-

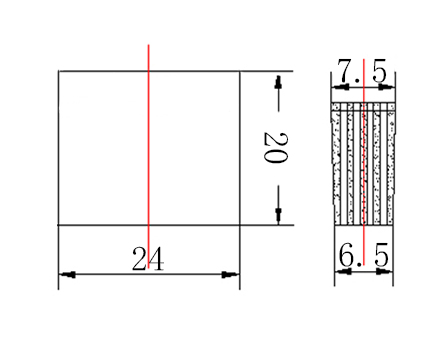

The first type of clients:They mainly use diamond single saws to process granite blocks. Because diamond single saws process stone, the cutting groove is narrower, which can reduce the waste of stone to a certain extent. This kind of customer mainly deals with expensive stone. In the selection of the segment, the saw blade is cut smoothly and has high precision. Yintian adopts the corresponding content and thickness design for the characteristics of the single saw, and the cutting edge has high cutting efficiency, which improves the finished product rate of stone processing.

-

The second type of clients:they have a large amount of stone processing, using a combination saw with large and small pieces of synchronous and high efficiency to process stone blocks. The hardness of the cutting head welded to the combination saw is high and the grinding resistance is good. The cutting effect in stone is perfect. At the same time, it is also possible to require high efficiency in stone processing. Yintian combination saw head is used in various combinations such as multi-piece combination, large-size combination, large and medium-sized combination. Using self-produced high-strength diamond as raw material, the product has good sharpness, wear resistance, strict production process and precise size, which guarantees the excellent quality of the product.

-

The third type of clients:They are mainly used for the mining of granite mine blocks. The mining segment tend to be too high in the middle or too low in the middle when cutting the blocks. Yintian mining tools used for mine mining are used in the last layer and the middle. High, stable quality, many sawing meters, good speed, the segment does not run off, the middle and the side layer are as high as they are used up, there will be no middle convex phenomenon, and the saw will not wear due to the bad segment. Sheets, cutting the number of meters can reduce the number of welding, extend the life of the saw blade, and improve mine production efficiency.

-

The fourth category of customers:They are inexperienced when purchasing the segment, and often choose the kind of shiny head, but the cutting effect after purchase is very unsatisfactory. The segment is judged according to the thickness and height difference of the diamond cutter segment whether the outer circle is flat. The degree of sharpness is very unscientific. The most important thing about a really good segment is its high sharpness and durability. High sharpness requires that the diamond of the segment be sharpened and the diamond can be clearly exposed. The other is to look at the tightness of the cutter body. The tighter the segment, the higher the holding force of the diamond.

-

The fifth category of customers:The hardness of the stone they saw and cut is higher, so the first consideration is the sharpness of the segment when purchasing the segment. The general segment is within a certain range, the lower the diamond content, the saw blade The sharpness and sawing efficiency are higher, and the service life is shorter. Conversely, the higher the diamond content, the lower the sharpness and sawing efficiency of the saw blade, and the longer the service life. Yintian uses different content for this kind of problem. Different thickness and fine particle design, the segment can be perfectly cut and cut more when cutting hard stone.

-

The sixth category of customers:the stone they cut is mainly loose and easy-cut stone such as sesame white. This kind of stone material is loose, but the stone particles are more. These customers usually choose some economical segment, but this The segment is generally not sharp enough, and the chipping is prone to chipping or uneven cutting, the yield of the stone is lowered, and the processing cost is increased. Yintian designed the blade for such loose and easy-cut stone, while ensuring economical benefits, it can also ensure the sharpness of the segment, and the cut stone will not be flattened.

.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

- comments in total【Write a Review】Customer Reviews