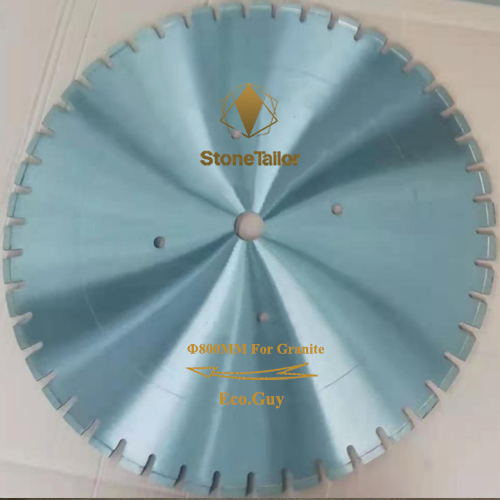

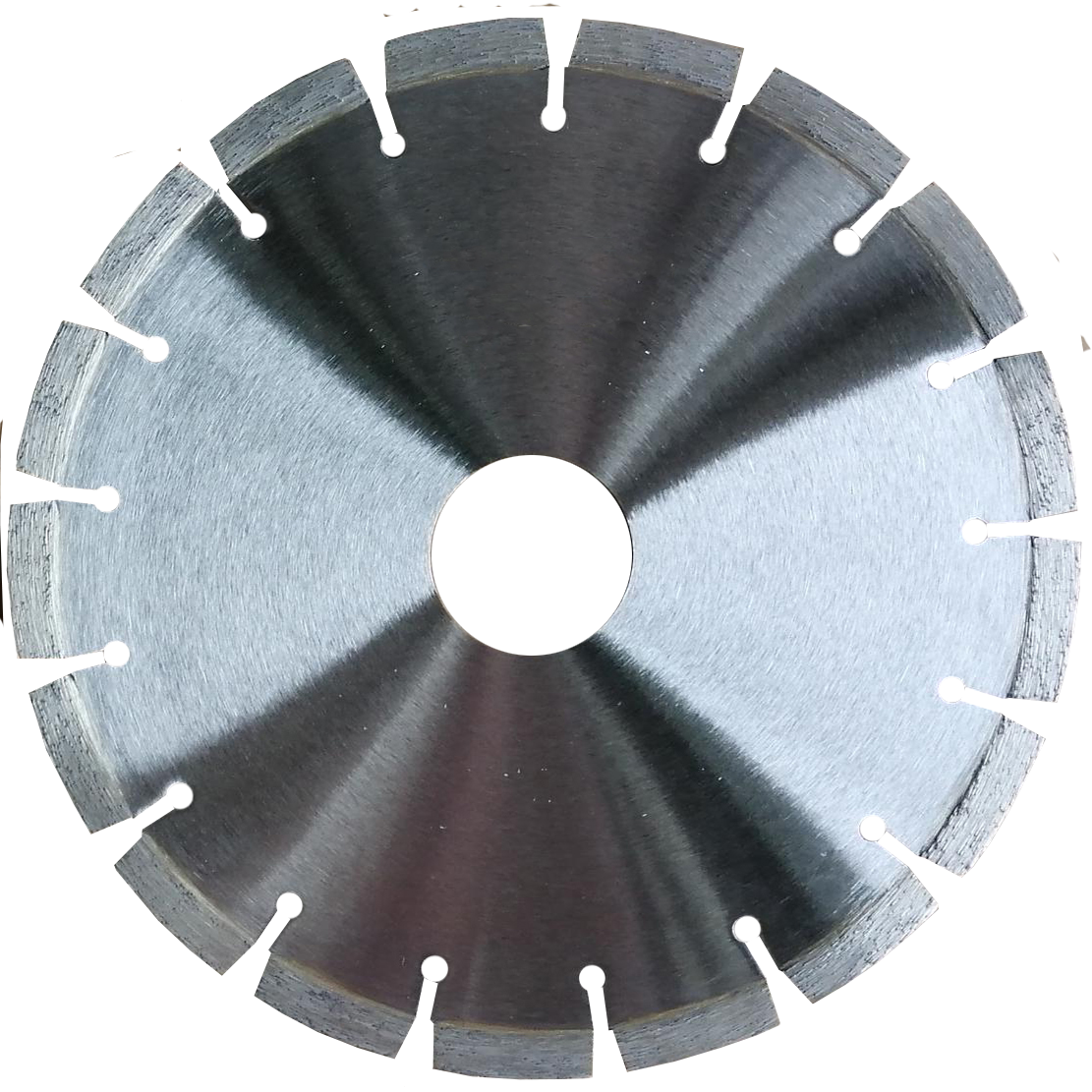

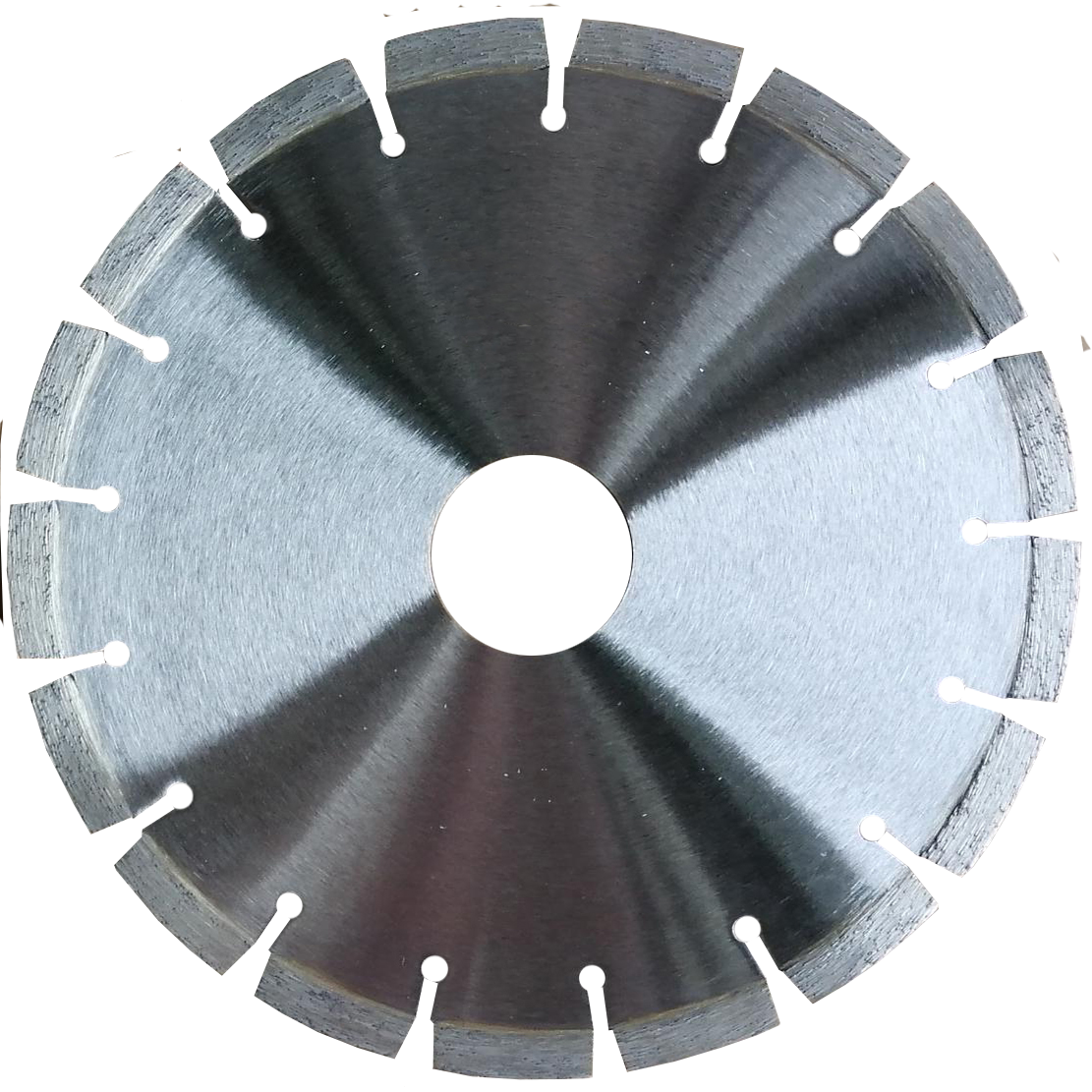

Diamond cutting blade is kind of cutting tools and widely used for processing hard and brittle material such as granite,marble,concrete,ceramics etc.The sharpness and durability are two main factors influence the saw blade cutting effects.In the eyes of ordinary people, saw blades made of metal materials often have the impression of being strong and wear-resistant, but in fact these so-called cutting tools are not so invincible as we think.For example,using the saw blade to cut some stones,the hard characteristics of the stone will make the saw blade lose its original impression instantly.In the daily use of the various blades,if we wanna prolong the working lifespan of blade,the durability has to be improved.As the hardest stone among them,granite’s hardness is a big test for the durability of blade.

.jpg)

Generally speaking,the durability is related to its raw material and formula.The higher the quality of the raw materials, the more professional the formula. Of course, the higher the wear resistance of the saw blade, the longer the working lifespan.However, the disadvantages of poor wear resistance and short working lifespan have always been the main reasons for restricting its development.

In the daily cutting process, the common problems such as poor quality of the segment and cracks between the segment and the blank saw blade are frequent factors that seriously affect the wear resistance of the saw blade.On the one hand,when the formula is not advanced,it’s obvious that the segment will not sharp enough to cut granite well, the segment will wear out quickly,what’s worse cutting efficiency is reduced.On the other hand,due to the backward production technologies,the welding outcome is not so good and there are some cracks caused between segments and blank saw.When weld line is not straight or even,it’s easy to cause segments to damage and produce the breaking and chipping of granite slabs.Once the similar problems occur for a long time but can’t be solved properly,it will inevitably lead to an increase in saw blade consumption and waste granite material.

In order to overcome these disadvantages,Hubei YINTIAN adopted excellent crystal,original formula and superior welding technology to develop a Durable King Granite Saw Blade with very long working lifespan after continuous research and test.Based on the high sharpness,YINTIAN Durable King granite saw blade is excellent balance of wear-resistance and sharpness.The excellent crystal produce high-quality segments,which is the premise of very long durability and greatly prolong the lasting lifespan and make full use of the value of granite saw blades.

.jpg)

The Durable King of YINTIAN Granite Cutting Blade is very long lasting lifespan and have a ideal wear-resistance and strong continuous operation.It can be lower the production cost and enhance production efficiency and reduce the labor intensity of workers.Taking Brazil Durable King Granite saw blade as an example,it can reach 380 square meters when cutting 2cm thickness granite slabs.The working lifespan is much longer than other brand identical products’.

.jpg)

Except the very long lasting working life,Durable King Diamond Disc for Granite is suitable for the common hardness granite stones.It will cut the common hard granite species very fast,stable and wear-resistant without breaking and chipping phenomena.There is a very beautiful and smooth straight line after cutting.The feature of long lasting life with extra wear resistance and excellent cutting result,let Durable King deeply won the customers’ trust and support and also strengthen competitiveness of Hubei YINTIAN and attract more and more customers.

.jpg)

India is a major producer of natural stones,among the exported stones, granite slabs is the first.Mr. MOHA is one of the owners of many stone shops and runs a large-scale stone processing factory in the suburbs of New Delhi.Recently,Mr MOHA found YINTIAN through the Internet and told to us the reason why he’s so eager to find a manufacturer of cutting blade.He said because cutting effect of previous granites are not so stable and wear-resistant,which seriously affected the delivery time of the factory to customers and further impacted the credit.This time,they hope to find a manufacturer that has high cost effective and stable effect products and can guarantee the long-term stable and sufficient supply.After getting this information,Hubei YINTIAN recommended Durable King Granite Saw Blade to him.This is granite blade with long last lifespan and wear resistant,the longest lifespan can reach 500 meters.Mr.MOHA felt satisfied with Durable King after several time trial order.He said that it is just what he wants and it totally solved the problems he faced and then there is no need to change the blade frequently any more.And Durable King greatly increase their working efficiently.Now Mr.MOHA is our regular customer.

.jpg)

The segments of Hubei YINTIAN stone cutting blade has been optimized and updated for many times in formula and process.we has been committed to technology research and development and improvement, and maintains the leading position in product formula and technology.Taking processing efficiency into account,Hubei YINTIAN Diamond Tools specially developed Durable King Granite Granite Cutting Blade.It has absolutely advantages of working lifespan and ideal cutting effects for common hardness granite stones. It is your dream cutting tools for common hard granite species.

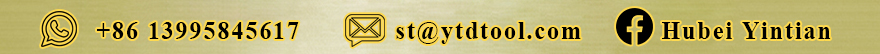

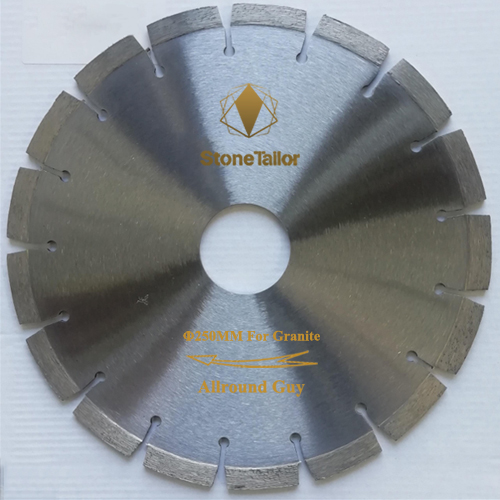

| Products Guiding Map 01 For Granite Saw Blade |

| Item |

Diameter |

Picture |

Type |

Spec. |

Holes/Slot |

Series |

Code |

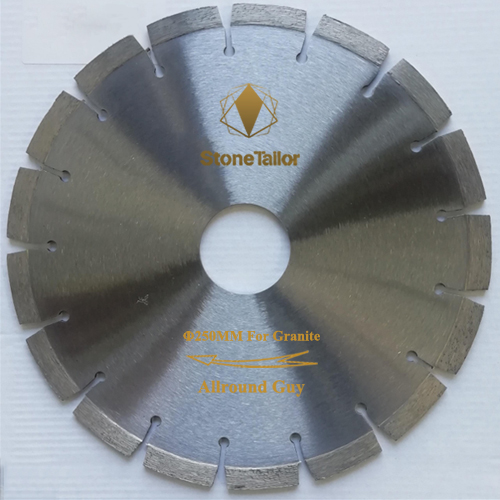

1

|

250MM

10''

|

|

Normal

Silent

|

(40*3.2*12)

*(50*2.2*17)

|

None Holes

K Slot

|

Allround

Guy

|

02

|

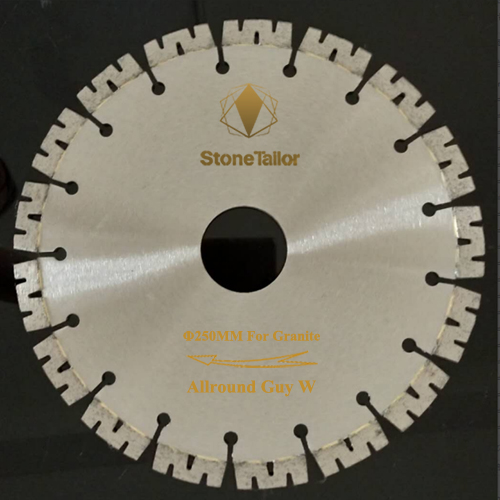

2

|

250MM

10''

|

|

Normal

Silent

|

(40*3.2*15.2

*(50*2.2*17)

|

None Holes

K Slot

|

Allround

Guy

|

02

|

3

|

250MM

10''

|

|

Normal

Silent

|

(40*3.3*12)

*(50*2.2*17)

|

None Holes

K Slot

|

Durable King

|

07

|

4

|

300MM

12''

|

|

Normal

Silent

|

(40*3.3*12)

*(50*2.4*21)

|

4 Holes

K Slot

|

Allround Guy

|

02 |

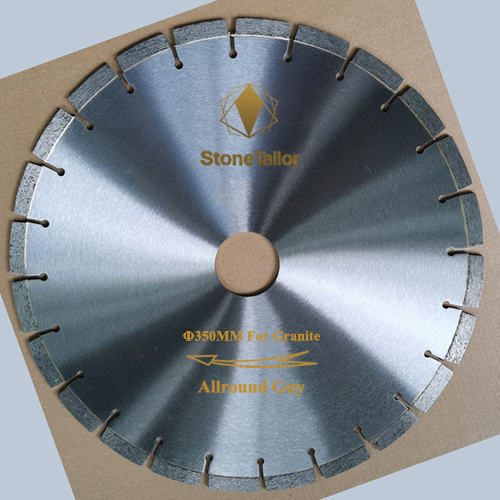

5

|

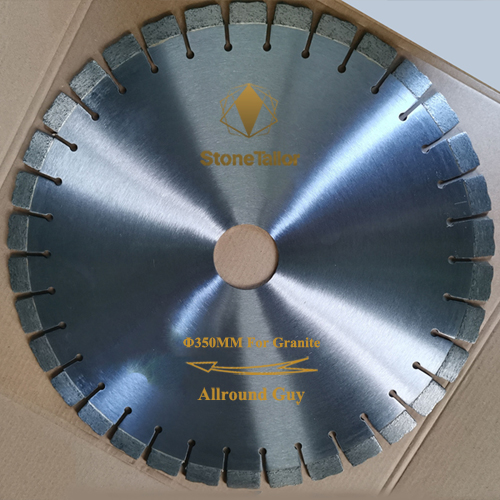

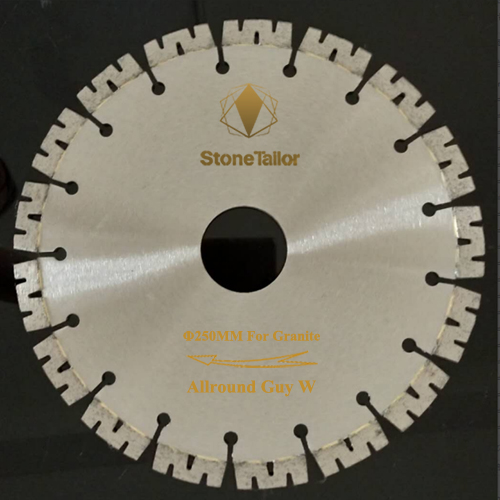

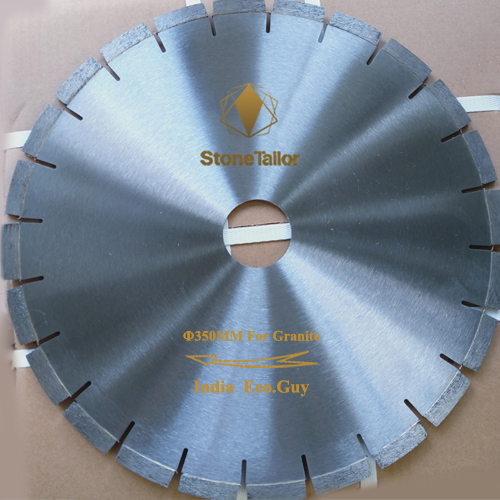

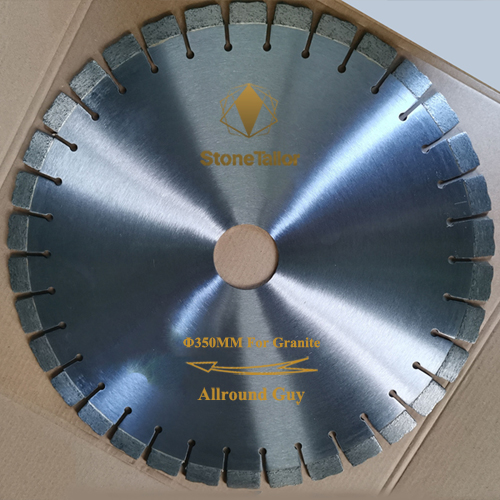

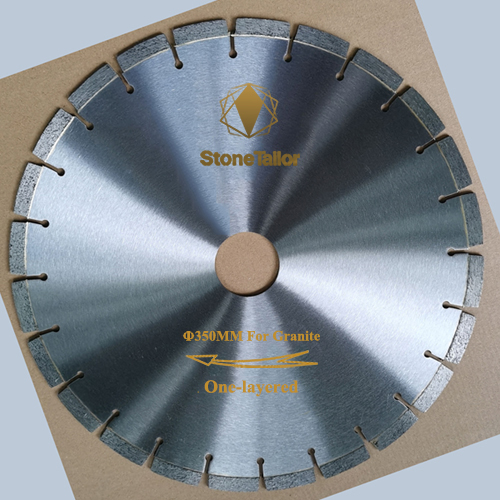

350MM

14''

|

|

Normal

Silent

|

(40*3.3*12)

*(50*2.4*24)

|

None Holes

K Slot

|

Allround Guy

|

02 |

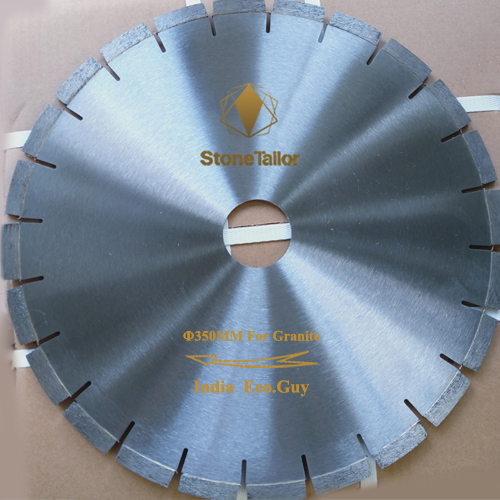

6

|

350MM

14''

|

|

Normal

Silent

|

(40*3.3*12)

*(50*2.4*24)

|

None Holes

U Slot

|

Eco.Guy

|

09 |

7

|

350MM

14''

|

|

Normal

Silent

|

(27*3.3*15/14)

*(50*2.4*34)

|

None Holes

K Slot

|

Allround Guy

|

02 |

8

|

350MM

14''

|

|

Normal

Silent

|

(40*3.3*15.2)

*(50*2.4*24)

|

None Holes

K Slot

|

Sharp King

|

05 |

9

|

350MM

14''

|

|

Normal

Silent

|

(40*3.3*15.2)

*(50*2.4*24)

|

None Holes

K Slot

|

Sharp King

|

05 |

10

|

350MM

14''

|

|

Normal

Silent

|

(40*3.3*15.2)

*(50*2.4*24)

|

None Holes

K Slot

|

Eco.Guy

|

09 |

11

|

350MM

14''

|

|

Normal

Silent

|

(40*3.2*12)

*(50*2.4*24)

|

None Holes

U Slot

|

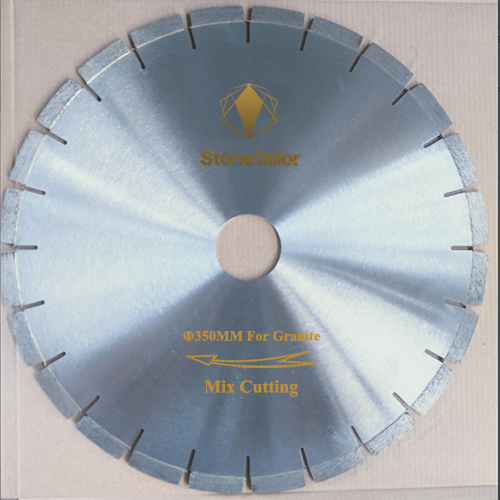

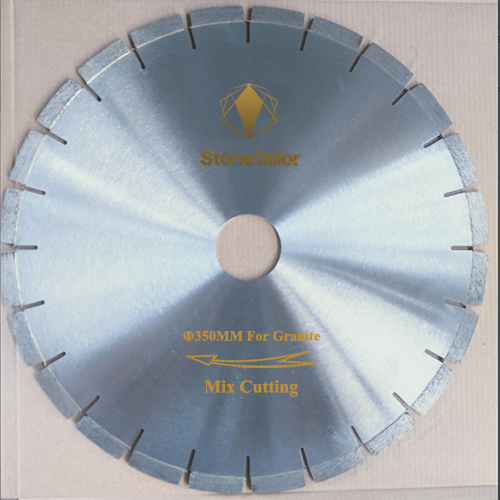

Mix Cutting

|

|

12

|

350MM

14''

|

|

Normal

Silent

|

(40*3.2*12)

*(50*2.4*24)

|

None Holes

U Slot

|

Mix Cutting

|

|

13

|

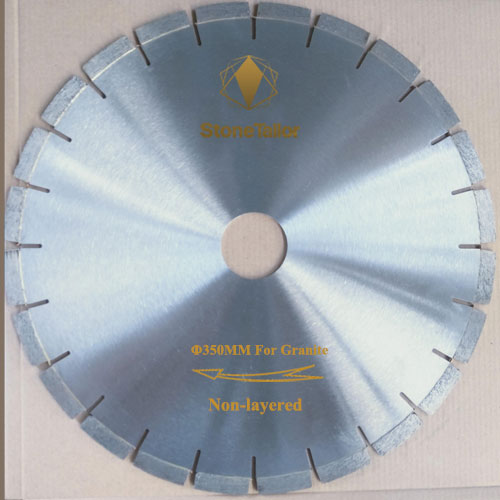

350MM

14''

|

|

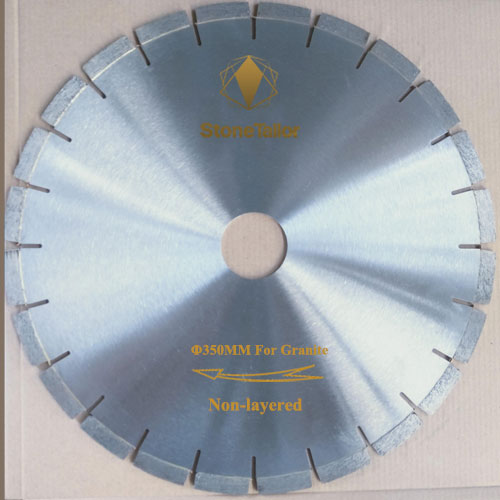

Normal

Silent

|

(40*3.3*12)

*(50*2.4*24)

|

None Holes

U Slot

|

Non-layered

|

|

14

|

350MM

14''

|

|

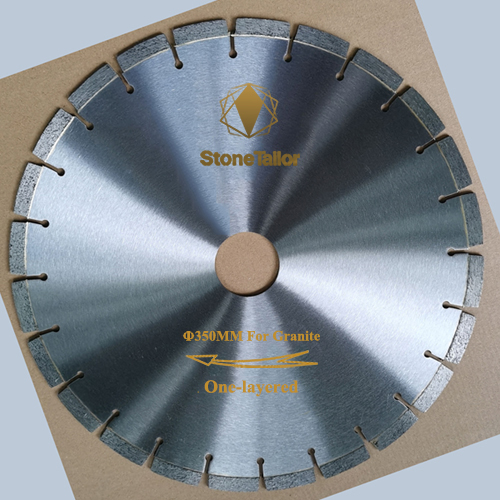

Normal

Silent

|

(40*3.3*12)

*(50*2.4*24)

|

None Holes

K Slot

|

One-layered

|

|

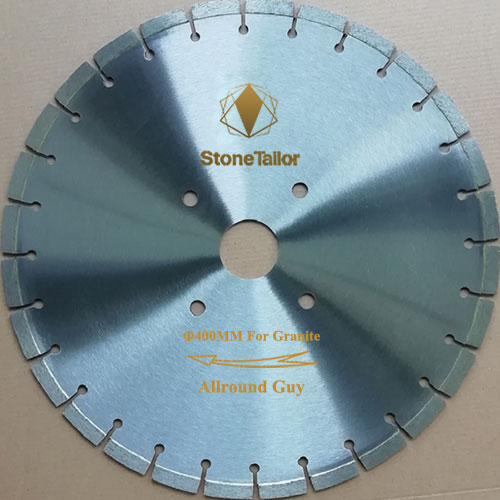

15

|

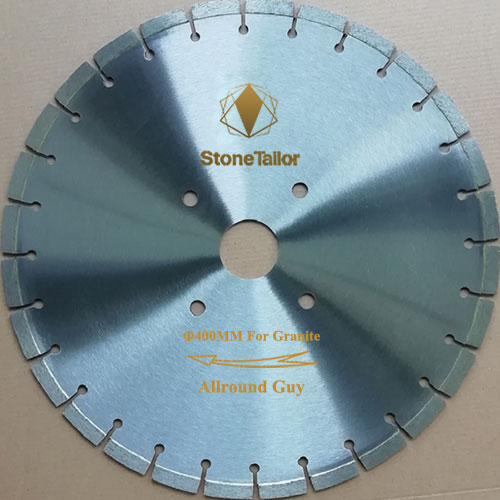

400MM

16''

|

|

Normal

Silent

|

(40*3.7*12)

*(50*2.8*28)

|

None Holes

K Slot

|

Allround Guy

|

02 |

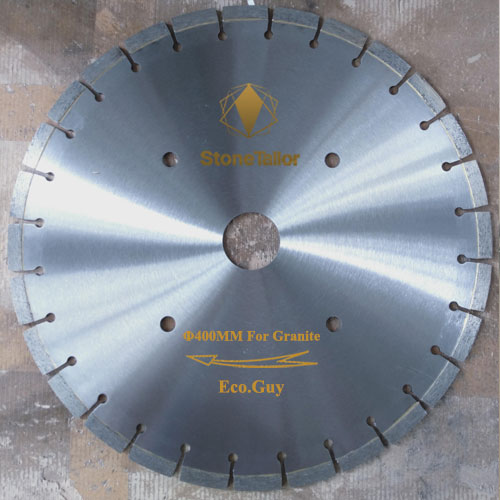

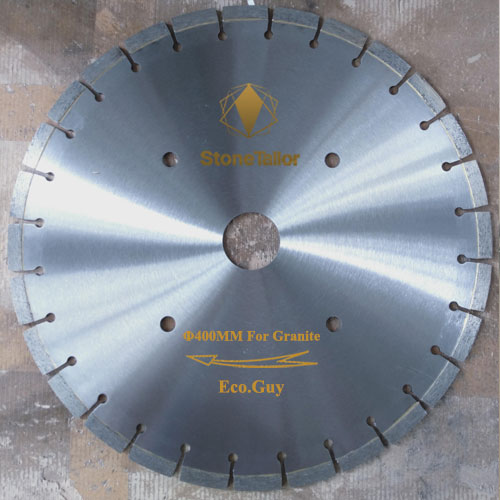

16

|

400MM

16''

|

|

Normal

Silent

|

(40*3.7*12)

*(50*2.8*28)

|

None Holes

K Slot

|

Eco.Guy

|

09 |

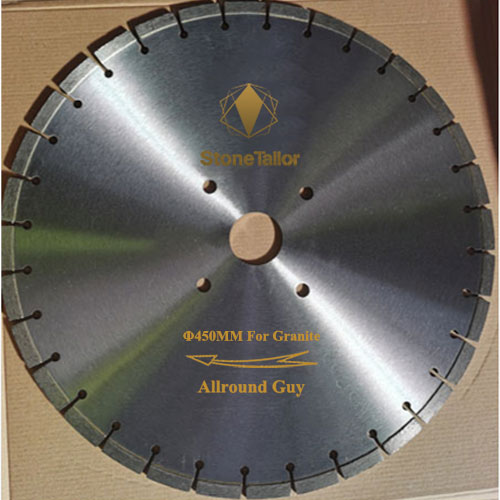

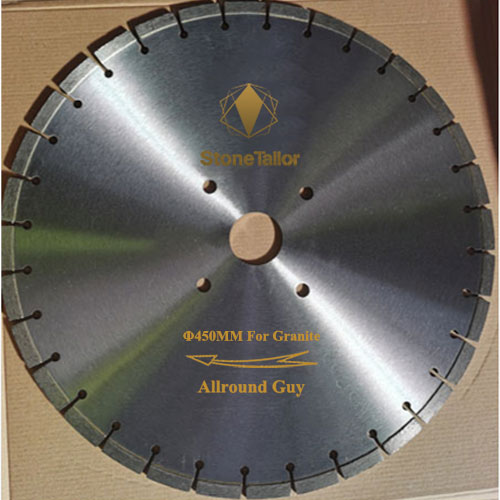

17

|

450MM

18''

|

|

Normal

Silent

|

(40*4.3*12)

*(50*3.0*32)

|

4 Holes

K Slot

|

Allround Guy

|

02 |

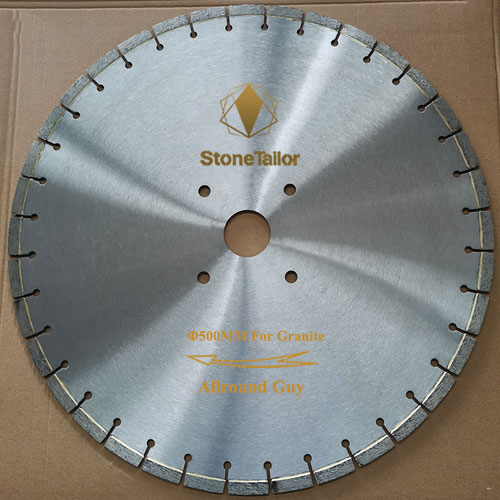

18

|

500MM

20''

|

|

Normal

Silent

|

(40*4.3*12)

*(50*3.0*36)

|

4 Holes

K Slot

|

Mix cutting

|

02 |

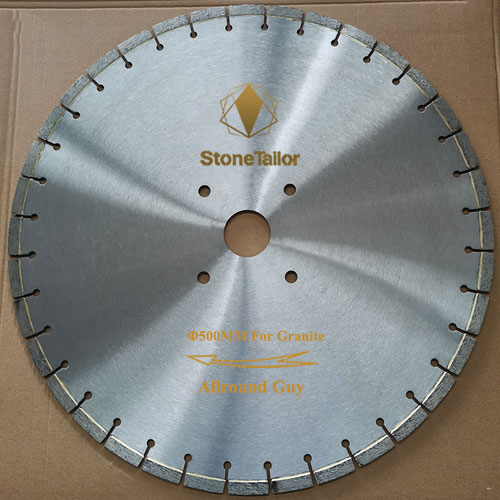

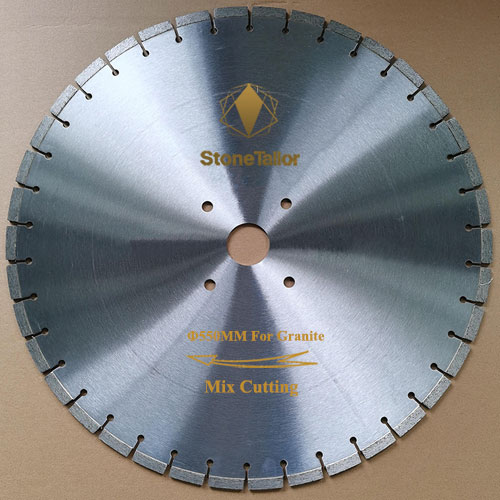

19

|

500MM

20''

|

|

Normal

Silent

|

(40*4.3*12)

*(50*3.0*36)

|

4 Holes

K Slot

|

Allround Guy

|

02 |

20

|

550MM

22''

|

|

Normal

Silent

|

(40*4.3*12)

*(50*3.6*38)

|

4 Holes

K Slot

|

Mix cutting

|

02 |

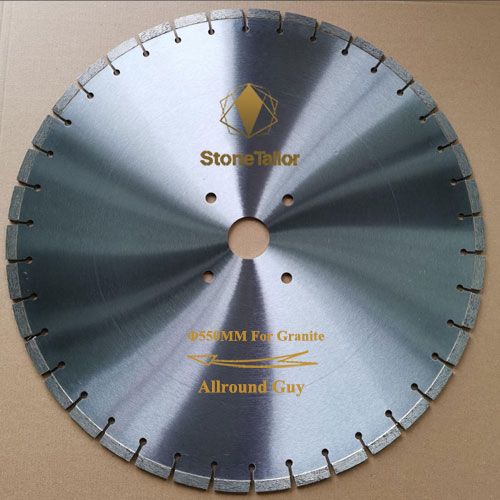

21

|

550MM

22''

|

|

Normal

Silent

|

(40*4.3*12)

*(50*3.6*38)

|

4 Holes

K Slot

|

Allround Guy

|

02 |

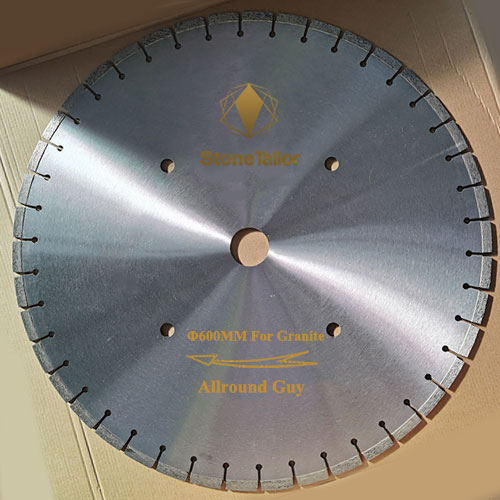

22

|

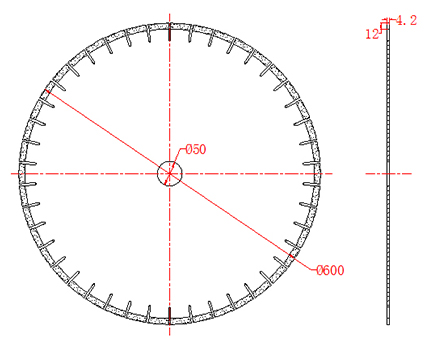

600MM

24'

|

|

Normal

Silent

|

(40*4.8*12)

*(50*3.6*42)

|

4 Holes

K Slot

|

Allround Guy

|

02 |

23

|

600MM

24'

|

|

Normal

Silent

|

(24*4.8*15/14)

*(60*3.6*58)

|

4 Holes

K Slot

|

Allround Guy

|

02 |

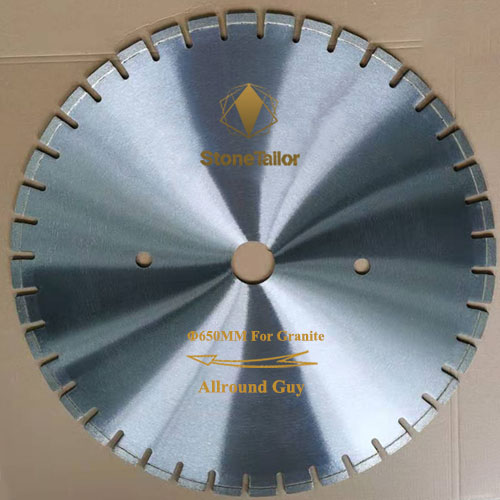

24

|

650MM

26'

|

|

Normal

Silent

|

(40*5.5*12)

*(50*4.0*40)

|

2 Holes

U Slot

|

Allround Guy

|

02 |

25

|

700MM

28'

|

|

Normal

Silent

|

(40*5.5*12)

*(50*4.0*40)

|

None Holes

U Slot

|

Eco.Guy

|

09 |

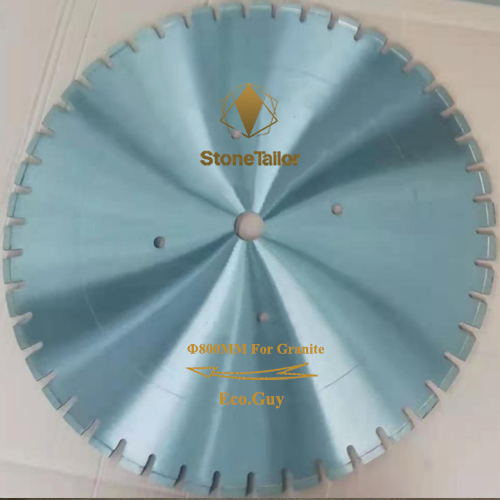

| 26 |

800MM

32'

|

|

Normal

Silent

|

(40*6.0*12)

*(50*4.5*46)

|

None Holes

U Slot

|

Eco.Guy

|

09 |

| Products Guiding Map 02 For Sintered Saw Blade |

| Item |

Diameter |

Picture |

Type |

Spec. |

Holes/Slot |

Series |

Code |

27

|

110MM

4.3'

|

|

Turbo-rim

|

(13*10)

*(1.0*72*20*Rim)

|

/

|

Allround Guy

|

02

|

28

|

110MM

4.3''

|

|

Segmented

Blade

|

(1.4*10)

*(1.0*8*20)

|

/

|

Allround Guy

|

02

|

29

|

110MM

4.3''

|

|

Segmented

Blade

|

(1.6*10)

*(1.0*8*20)

|

/

|

Allround Guy

|

02

|

| Products Guiding Map 03 For Limestone Segment |

| Item |

Diameter |

Picture |

Type |

Spec. |

Holes/Slot |

Series |

Code |

|

30

|

1600MM

64''

|

|

6.5/7.2/8/9

|

24*7.5*15

|

70

|

Allround Guy

|

02

|

| Products Guiding Map 04 For Granite Segment |

| Item |

Diameter |

Picture |

Type |

Spec. |

Holes/Slot |

Series |

Code |

31

|

800MM

32''

|

|

4.5

|

40*6.4*12

|

46

|

Allround Guy

|

02

|

32

|

1000MM

40''

|

|

6.5/7.2/8/9

|

24*7.2/6.4*15/14

|

80

|

Allround Guy

|

02

|

33

|

1600MM

64''

|

|

6.5/7.2/8/9

|

24*8.2/7.6*15/14

|

108

|

Allround Guy

|

02

|

34

|

1800MM

72''

|

|

6.5/7.2/8/9

|

22*10/9.4*15/14

|

120

|

Allround Guy

|

02

|

35

|

2000MM

80''

|

|

6.5/7.2/8/9

|

24*10.3/9.7*15/14

|

128

|

Allround Guy

|

02

|

36

|

2000MM

80''

|

|

6.5/7.2/8/9

|

24*10.3/9.7*15/14

|

128

|

Allround Guy

|

02

|

37

|

2000MM

80''

|

|

6.5/7.2/8/9

|

24*11.2/10.6*14/13 |

128

|

Allround Guy

|

02

|

| Products Guiding Map 05 For Sandstone Segment |

| Item |

Diameter |

Picture |

Thickness |

Spec. |

Seg. Number |

Series |

Code |

38

|

1600MM

64''

|

|

7.2

|

24*9.6/8.8*20 |

108 |

Allround Guy |

02 |

39

|

1600MM

64''

|

|

7.2

|

24*9.0/8.4*15/14 |

108 |

Allround Guy |

02 |

40

|

1600MM

64''

|

|

7.2

|

24*9.0/8.4*15/14 |

108 |

Allround Guy |

02 |

41

|

1600MM

64''

|

|

7.2

|

24*9.0/8.4*15/14 |

108 |

Allround Guy |

02 |

42

|

1600MM

64''

|

|

7.2

|

24*10.2/9.6*15/14 |

108 |

Allround Guy |

02 |

43

|

1600MM

64''

|

|

7.2

|

24*9.6/8.8*20 |

108 |

Allround Guy |

02 |

-

Durable King Cutting The Golden Diamond Grain

-

Durable King Cutting The Plateau Snow

-

Durable King Cutting The Imperial Red

Durable King Cut the Antique Green

use for stone table, stone stool

-

Durable King Cut

the Golden Aspen use for indoor floor

-

Durable King Cut the Shidao Red

use for building outer walls

-

Durable King Cut the

Mongolia Black use for outdoor floor

.jpg)

-

The first type of clients:They have too many visitors or business to deal with, there is not much time to find a manufacturer to match the different orders, therefore, they are more inclined to look for a strong R & D capability, large production scale, short delivery period, stable quality suppliers to meet the needs of various orders of different customers.

-

The second type of clients:They came to China from far away, trying to find a universal blade which can cut their own country's different hardness of stone so that can not only save their time, at the same time, it can reduce waste in different degrees.

-

The third type of clients:They have a strong sense of safety and environmental protection, the project should be reduced to the lowest degree of every link, In the process of cutting stone the worker's injury was caused by the fall of the segment is absolutely intolerable, these have a great impact on the duration of the project, each of them is a huge loss of security incidents.

-

The fourth category of customers:They have a wide range of customers, In the area of stone also has its own characteristics, the cutting requirements and quality requirements of the blade is not the same, so they've been looking for a saw blade manufacturer that can solve this problem perfectly, but the saw blades they bought before are not ideal, It was not until they knew that Yintian could meet all kinds of requirements with different formulations, and they really got rid of their worries.

-

The fifth category of customers:They have a large number of projects, the construction period is also special instancy, Therefore, when selecting the saw blade, they are more concerned about the sharpness and wear resistance,In the process of cutting stone, collapse, drop angle and other issues will be a serious waste of their precious time

-

The sixth category of customers:The stone which they processed has a complex composition, containing a higher composition of quartz, stone material product value is expensive and difficult to cut, so they must find a high degree of sharp saw blade to meet the needs of their quality and cost.

.jpg)

_3.jpg)

Mr. Bassam, Owner of Mkatbi company, KSA

Every time I come to China, I visit Yintian Company first, for me, they are not just my OEM supplier but also my good friends and partners, we met in 2010, after 3 times testing, I was sure Yintian diamond blade was much sharper than any other supplier's, and it can cut all kinds of granite slabs of different hardness. But at that time, my company is just starting and have a small order, Yintian supported my idea to establish my own brand, from then on, our quantity gets bigger and bigger, the varity gets more and more and demands of the package and printing request gets higher and higher, without exception, they meet our requirements in the contract. I'm quite satisfied with Yintian.

Noel Rosa, Brazil TG Diamond Tools Company.

I've distributed Yintian's marble saw blade including jade stone saw blade for 2 years. My evaluation is "Do More with Less" due to its several advantages. First, it has sharp, fast and stable cutting performance with low power consumption. Second, it has longer lifespan which cuts nearly 2000 ㎡ Giallo Reale with 16 days, Third, it has smooth and straight cutting lines without chipping, especially when cutting Aran White, Fourth, it is able to save cost in two ways: save cost of labor and electricity by its fast cutting; save stone slabs by good cutting performance without breaking and chipping

Gamal Abdul Nasser, Libyan dealer, Amamar Stone Tool Company.

I come from a small town, Tazerbo, in Libya, and I have done diamond saw blade business in capital city Tripoli for 3 years, In the first year, without finding stable qualified supplier, I had to ask my friends in Tripoli who have stone factories here for help, and sold the saw blades to them, In 2003,I found Yintian Company in Xiamen stone fair, and I thought they are very professional, So I asked my Chinese friend to help me buy some saw blades to have test in different factories of my friends, Surprisedly, the cutting result is very good. Especially, Yintian high-grade saw blade can cut various granite and marble in different hardness with high speed and no chipping ,and its lifespan can reach 1000 ㎡.Now, my business gets better and better, and I am thinking about setting up a Yintian agent in Libya.

.png)

.jpg)

.png)

.jpg)

.png)

.jpg)

.png)

.jpg)

.png)

.jpg)

.png)

.jpg)

.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

_1(1).jpg)

_2.jpg)

_3.jpg)

- comments in total【Write a Review】Customer Reviews