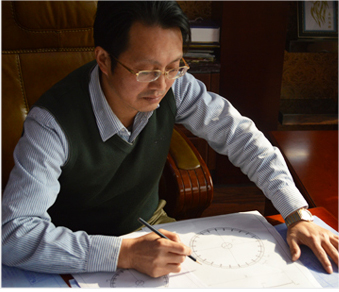

In 1991, Mr. Xiong Caihua, driven by desire and passion to construct his hometown, returned to Ezhou as soon as he graduated from ZhongNan Finance & Economics University, By the time, Chinese diamond tool industry was originated in Ezhou. Without hesitation, he devoted himself to R&D fomulas for diamond tools. From then on, he started his professional career of saw blade.

Thanks to his talent, hard-working, exploration and innovation, Mr. Xiong invevted 2SD Ultimate Balance Point Formula, which helped Yintian to solve the contradiction between sharpness and lifespan of a saw blad, and created the rudiment of Yintian All-Round King in 1994.which helped Mr. Xiong earn his First Pot of Gold althrough he was just running a small business.

In 1997, Mr. Xiong launched Hubei Yintian Dia-mond Tools Co.,Ltd. Later he gathered an expert team. In order to develop products fitting in well with the demand of stone processing, they often went deep into some typical large scale stone mining area and stone trade bases to do research. Additionally, they spent a lot of time in dissecting and studying diamond blades imported from German, Italy, Japan, Korean and America.

When time went by 2009, Yintian's annual sales scale exceeded 1 million pcs & sets. Aimed at long-term business in the international market, Lucy Lau, Mr. Xiong'wife,set up Overseas Business Department, and based on it, established Hubei Yintian Cutting Industry Co.,Ltd in 2012, developping highend blade &segment for the overseas market in OEM /ODM. Gratefully, their products have been sold well in more than 20 countries, such as Brazil, India, Turkey, Vietnam, Egypt, Jordan, Spain, Australia, Canada, Russia etc.

Offering OEM/ODM for overseas dealers helped Yintian broaden their vision in international markets. From 2012 to 2016, a large scale renewal & transformation of technical equipments took placed in Yintian. As the results, Yintian built more than 50 production lines with more than 100 sets of advanced equipments, including 72 process flow and 38 check & test procedures.Besides, They created a kind of flexible manufacturing technology to achieve ultra-high productivity,while perfectly providing customized saw blades & segments in precise delivery.

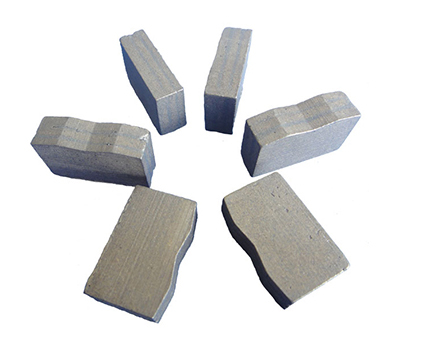

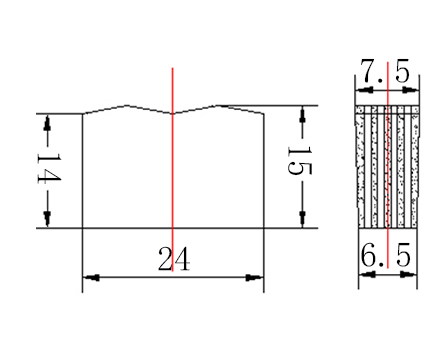

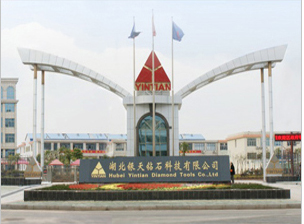

Up to now, Led by Mr. and Mrs. Xiong, Yintian Group has built two manufacturing enterprises, one trade company, and a pro-duction base—Yintian Science and Technology Industrial park in Ezhou, working out a series of products fitting in well with the demand not only in domestic but also in overseas, including more than 200 specifications & 1000 models welding saw blades, 100 kinds of sintered saw blades, and more than 60 models of segments for mining saw, etc., solving many kinds of tough problems in stone proessing.

Yintian do their best efforts in the feild for 20 years, making full use of essence of not only the local Industry but also the forien technology, growing up as one of the top enterprises. Yintian take it as their misson to supply the most perfect saw blade all over the world, take it as their vision to help stone processing easy, take it as their obligation to deserve every penny of the customers. Yintian will be dedicated to serve you forever !

.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

- comments in total【Write a Review】Customer Reviews