|

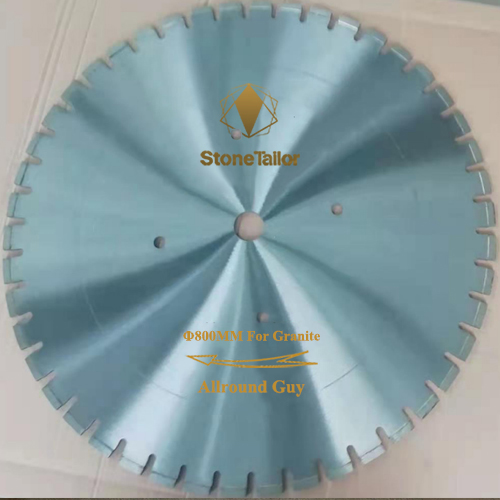

Diamond Saw Blade For Granite 01

|

| ITEM |

DIA.MM |

PICTURE |

TYPE |

SPEC.MM |

HOLES/SLOT |

SERIES |

CODE |

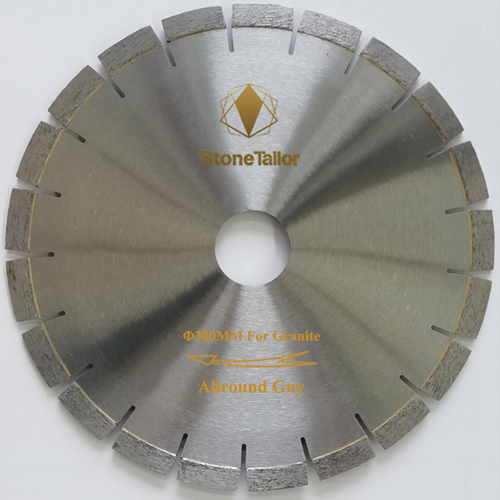

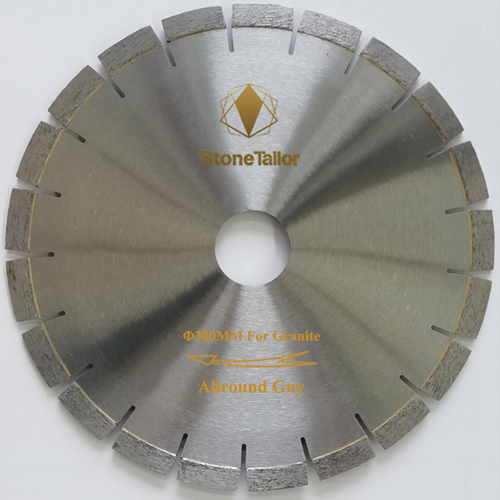

1

|

φ300

12”

|

|

Normal

Silent

|

(40*3.2*15)

*(2.4*21T*50) |

None Hole

U Slot

|

Allround

Guy

|

02

|

2

|

φ350

14''

|

|

Normal

Silent

|

(40*3.3*15)

*(2.4*24T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

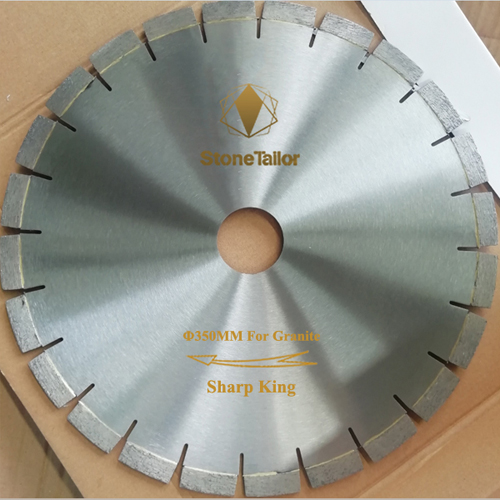

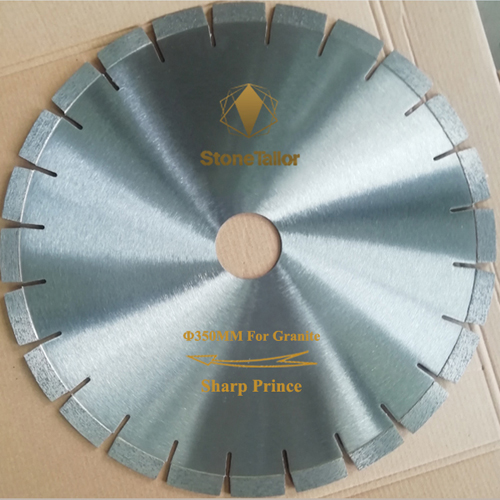

3

|

φ350

14''

|

|

Normal

Silent

|

(40*3.3*15)

*(2.4*24T*50)

|

None Hole

U Slot

|

Sharp

King

|

05

|

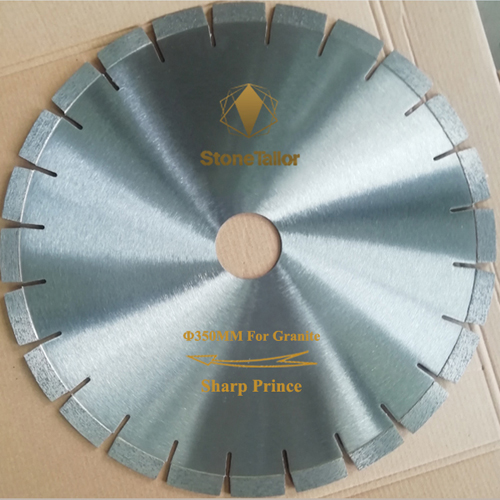

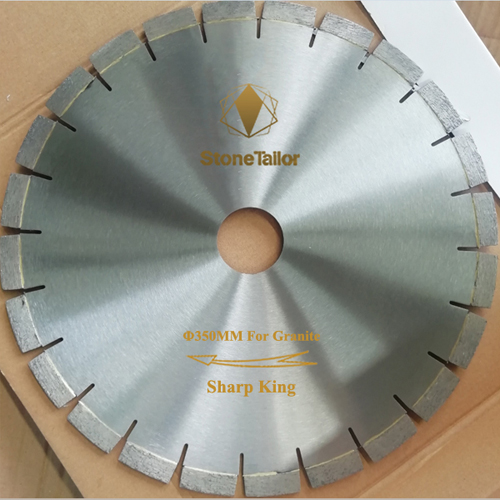

4

|

φ350

14''

|

|

Normal

Silent

|

(40*3.3*15)

*(2.4*24T*50)

|

None Hole

U Slot

|

Sharp

Prince

|

06

|

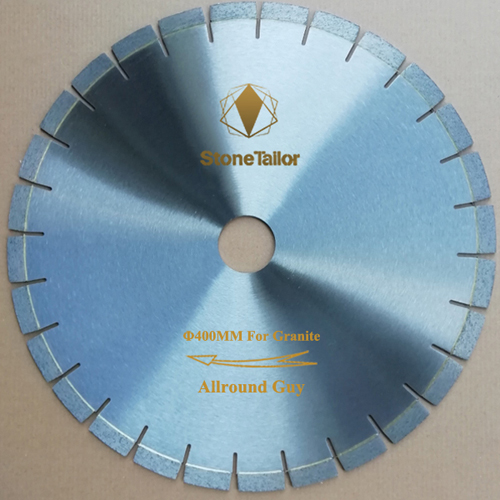

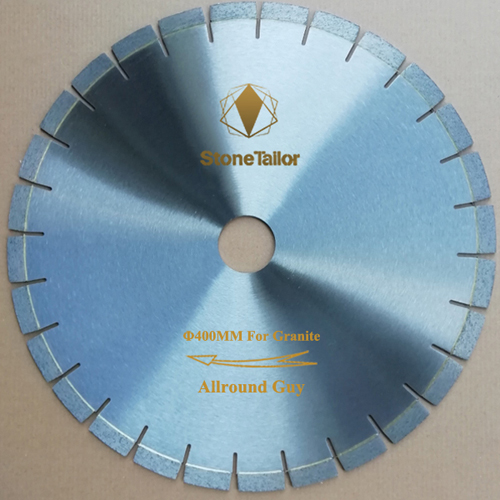

5

|

φ400

16''

|

|

Normal

Silent

|

(40*3.6*15)

*(2.8*28T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

6

|

φ450

18''

|

|

Normal

Silent

|

(40*4.2*12)

*(3.0*32T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

7

|

φ450

18''

|

|

Normal

Silent

|

(40*4.2*15)

*(3.0*32T*50)

|

4 Holes

U Slot

|

Allround

Guy

|

02

|

8

|

φ500

20''

|

|

Normal

Silent

|

(40*4.2*15)

*(3.0*36T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

9

|

φ500

20''

|

|

Normal

Silent

|

(40*4.2*12)

*(3.0*36T*50)

|

None Hole

U Slot

|

Practical

Guy

|

09

|

10

|

φ550

22''

|

|

Normal

Silent

|

(40*4.3*12)

*(3.2*38T*50)

|

None Hole

K Slot

|

Allround

Guy

|

09

|

11

|

φ600

24''

|

|

Normal

Silent

|

(40*4.8*12)

*(3.6*42T*50)

|

None Hole

U Slot

|

Practical

Guy

|

09

|

12

|

φ600

24''

|

|

Normal

Silent

|

(40*4.8*15)

*(3.6*42T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

13

|

φ650

26''

|

|

Normal

Silent

|

(40*4.8*12)

*(3.6*40T*50)

|

2 Holes

U Slot

|

Allround

Guy

|

02

|

14

|

φ700

28''

|

|

Normal

Silent

|

(40*5.5*15)

*(4.0*40T*50)

|

4 Holes

U Slot

|

Allround

Guy

|

02

|

15

|

φ750

30''

|

|

Normal

Silent

|

(40*5.5*12)

*(4.0*46T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

16

|

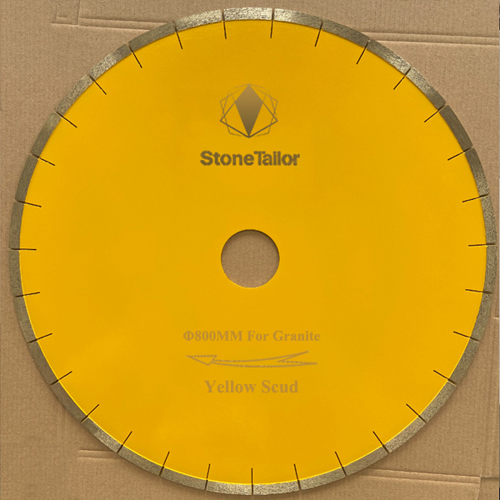

φ800

32''

|

|

Normal

Silent

|

(40*6.0*12)

*(4.5*46T*50)

|

4 Holes

U Slot

|

Allround

Guy

|

02

|

| Diamond Saw Blade For Marble 02 |

| ITEM |

DIA.MM |

PICTURE |

TYPE |

SPEC.MM |

HOLES/SLOT |

SERIES |

CODE |

17

|

φ300

12''

|

|

Normal

Silent

|

(40/39*2.7*8)

*(2.2*23T*50)

|

None Hole

Musical Slot

|

White

Angel

|

12

|

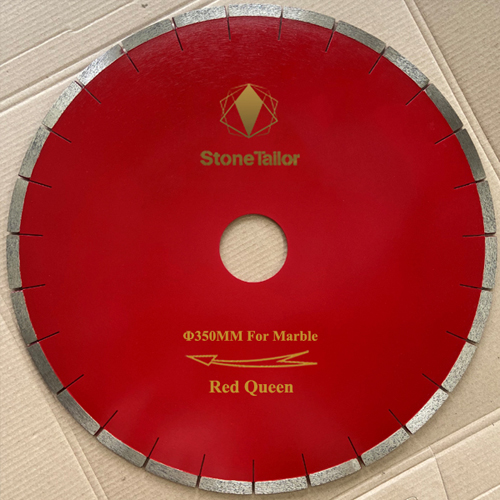

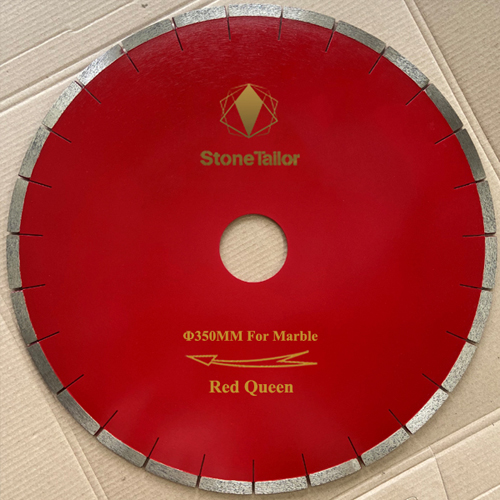

| 18 |

φ350

14''

|

|

Normal

Silent

|

(39/37.8*2.8*9)

*(2.3*27T*50)

|

None Hole

U Slot

|

Red

Queen

|

11

|

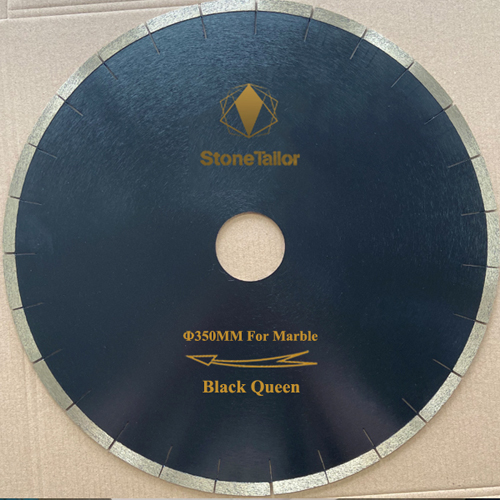

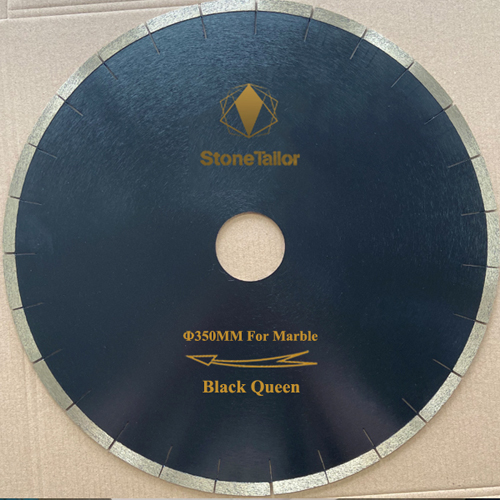

| 19 |

φ350

14''

|

|

Normal

Silent

|

(39/37.8*2.8*9)

*(2.3*27T*50)

|

None Hole

U Slot

|

Black

Queen

|

10 |

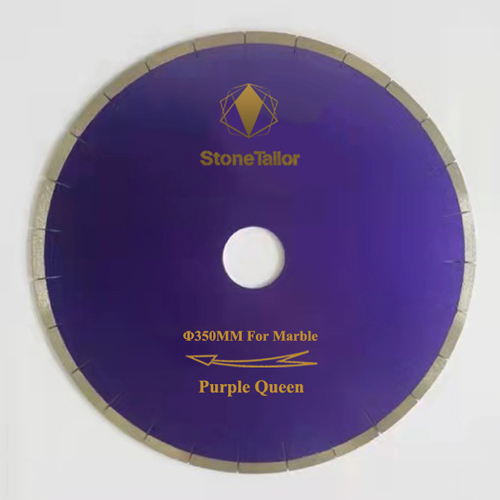

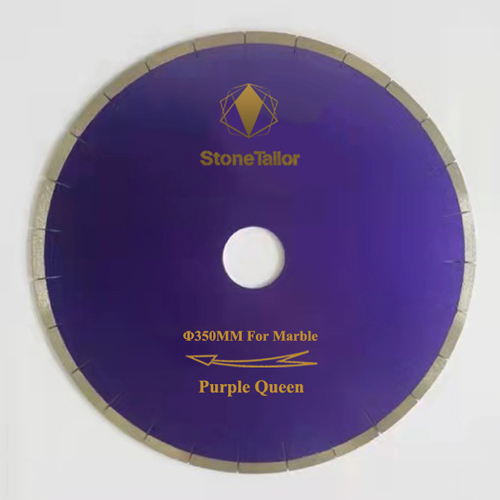

20

|

φ350

14''

|

|

Normal

Silent

|

(39/37.8*2.8*9)

*(2.3*27T*50)

|

None Hole

U Slot

|

Purple

Queen

|

10

|

21

|

φ350

14''

|

|

Normal

Silent

|

(40/39*2.7*8)

*(2.3*27T*50)

|

None Hole

Musical Slot

|

White

Angel

|

12

|

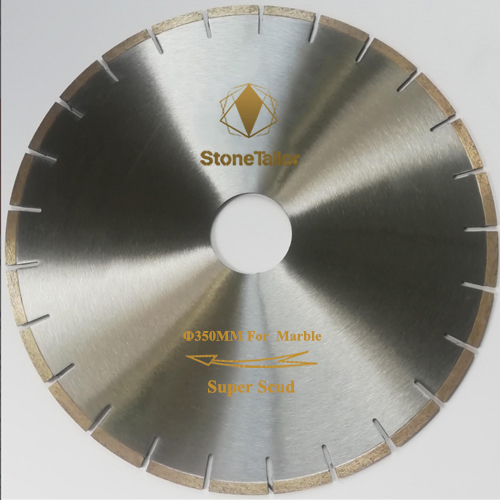

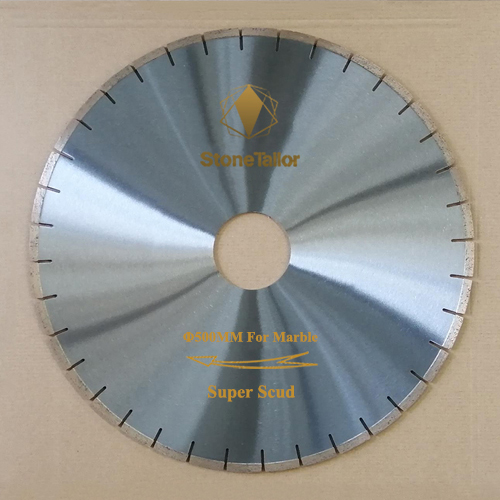

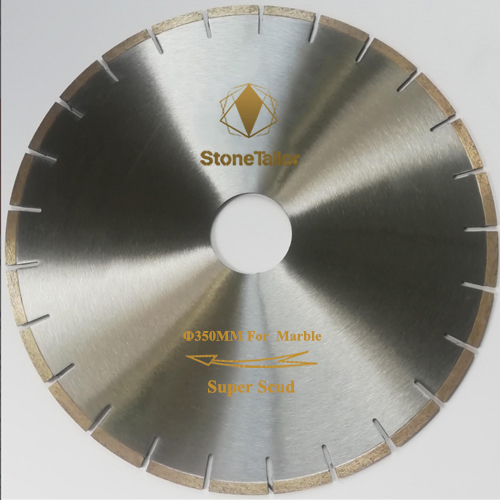

22

|

φ350

14''

|

|

Normal

Silent

|

(40/39*2.9*8)

*(2.3*27T*50)

|

None Hole

U Slot

|

Super

Scud

|

13

|

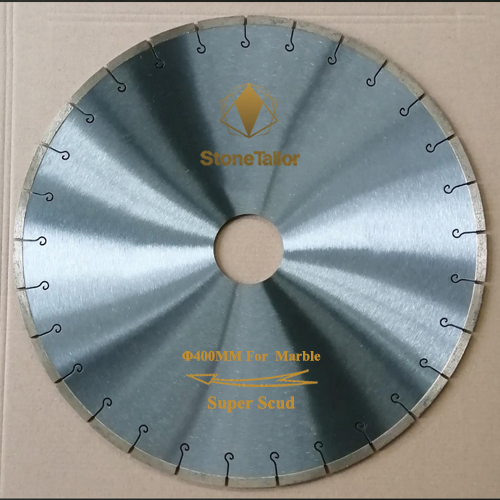

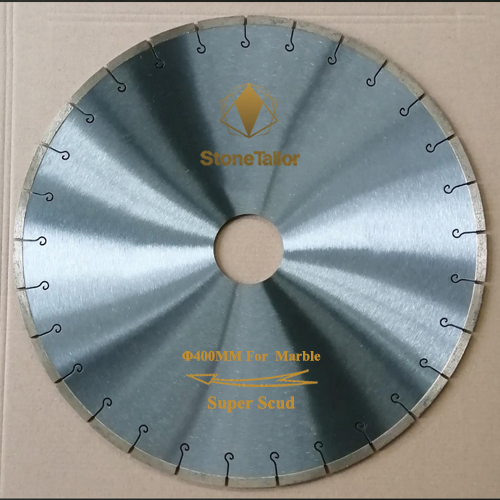

23

|

φ400

16''

|

|

Normal

Silent

|

(39/37.8*3.4*9)

*(2.6*31T*50)

|

None Hole

U Slot

|

Super

Scud

|

13

|

24

|

φ400

16''

|

|

Normal

Silent

|

(39/37.8*3.4*9)

*(2.6*31T*50)

|

None Hole

U Slot

|

Red

Queen

|

11

|

25

|

φ400

16''

|

|

Normal

Silent

|

(41.5/40*2.9*8)

*(2.2*30T*50)

|

None Hole

Musical Slot

|

White

Angel

|

12

|

26

|

φ350

14''

|

|

Normal

Silent

|

(43/41.5*2.9*8)

*(2.2*25T*60)

|

None Hole

U Slot

|

Super

Scud

|

13

|

27

|

φ400

16''

|

|

Normal

Silent

|

(40*3.6*10)

*(2.8*28T*60)

|

None Hole

U Slot

|

Super

Scud

|

13

|

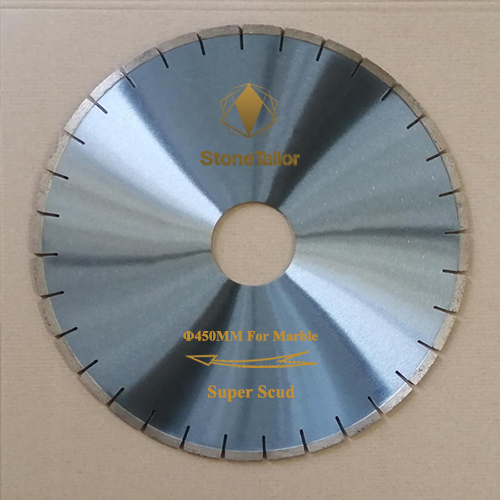

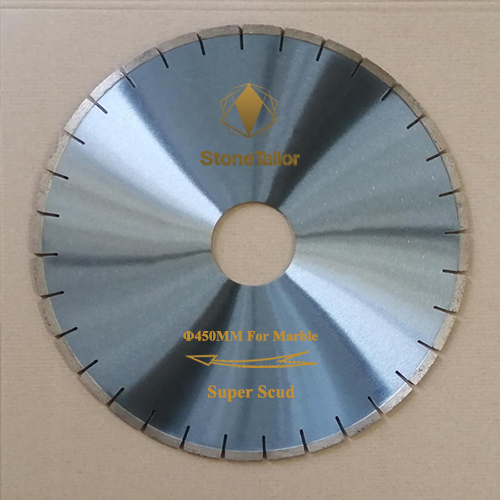

28

|

φ450

18''

|

|

Normal

Silent

|

(40*4.2*10)

*(3.0*32T*90/60)

|

None Hole

U Slot

|

Super

Scud

|

13

|

29

|

φ500

20''

|

|

Normal

Silent

|

(40*4.3*10)

*(3.0*36T*50)

|

None Hole

U Slot

|

Scud |

14

|

30

|

φ500

20''

|

|

Normal

Silent

|

(40*4.2*10)

*(3.0*36T*90/60)

|

None Hole

U Slot

|

Super

Scud

|

13

|

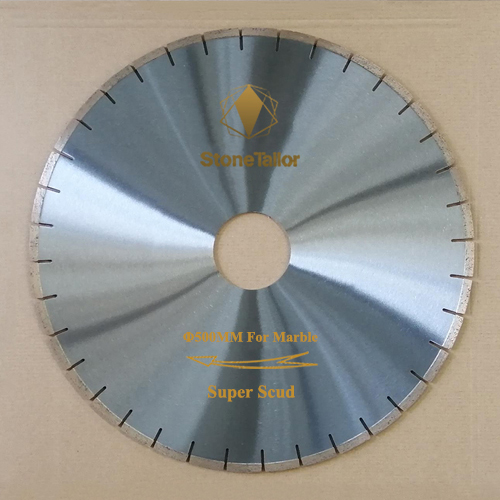

| 31 |

φ600

24''

|

|

Normal

Silent

|

(40*4.8*10)

*(3.6*42T*90/60)

|

None Hole

U Slot

|

Super

Scud

|

13

|

32

|

φ650

26''

|

|

Normal

Silent

|

(40*4.8*10)

*(3.6*40T*60)

|

None Hole

U Slot

|

Super

Scud

|

13

|

33

|

φ700

28''

|

|

Normal

Silent

|

(38*5.2*10)

*(4.0*40T*60)

|

None Hole

U Slot

|

Super

Scud

|

13

|

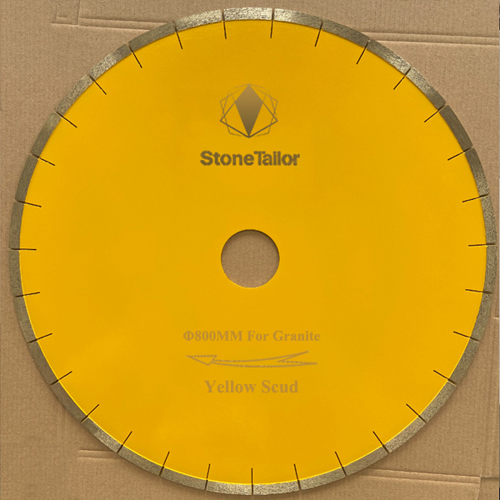

34

|

φ800

32''

|

|

Normal

Silent

|

(38*6.0*10)

*(4.5*46T*60)

|

None Hole

U Slot

|

Super

Scud

|

13

|

| Diamond Saw Blade For Sandstone 03 |

| ITEM |

DIA.MM |

PICTURE |

TYPE |

SPEC.MM |

HOLES/SLOT |

SERIES |

CODE |

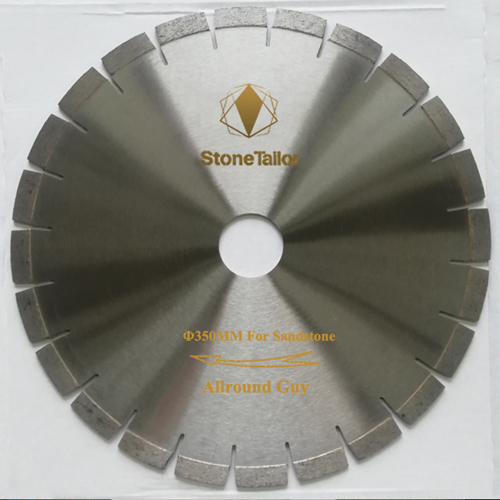

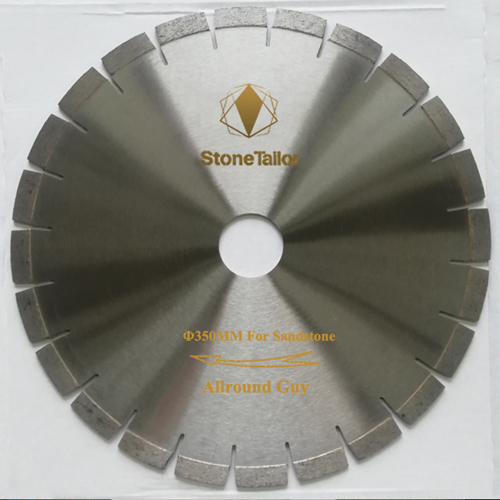

35

|

φ350

14''

|

|

Normal

Silent

|

(40*3.3*15)

*(2.4*24T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

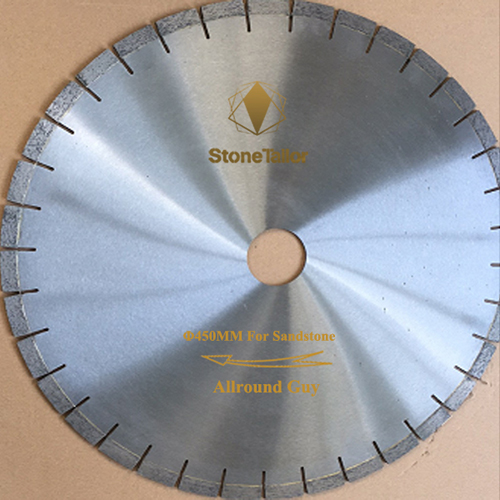

36

|

φ400

16''

|

|

Normal

Silent

|

(40*3.8*15)

*(2.8*28T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

37

|

φ450

18''

|

|

Normal

Silent

|

(40*4.0*15)

*(3.0*32T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

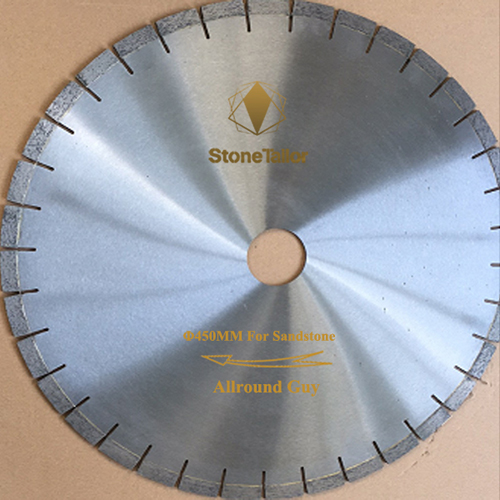

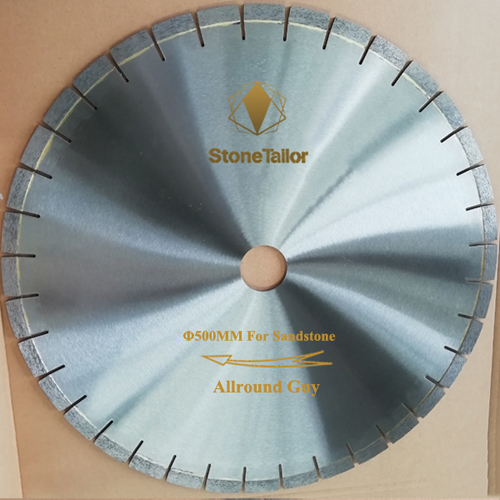

38

|

φ500

20''

|

|

Normal

Silent

|

(40*4.2*15)

*(3.0*36T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

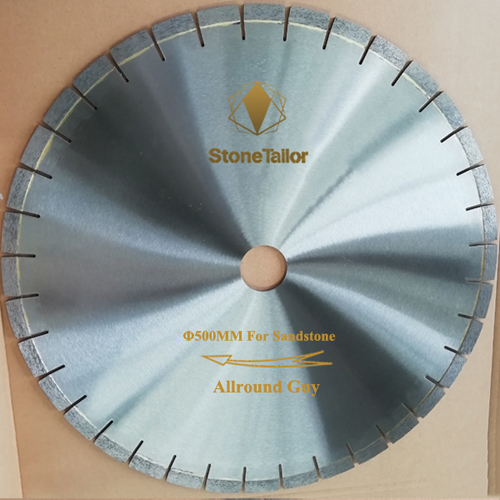

39

|

φ600

24''

|

|

Normal

Silent

|

(40*4.5*15)

*(3.6*42T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

| Diamond Saw Blade For Hot-press 04 |

| ITEM |

DIA.MM |

PICTURE |

TYPE |

SPEC.MM |

HOLES/SLOT |

SERIES |

CODE |

40

|

φ110

4.5''

|

|

Protective

-teeth

|

2.0T*10X*1.2E*

9Z*22.23H

|

None Hole

U Slot

|

Allround

Guy

|

02

|

| 41 |

φ115

4.5''

|

|

Protective

-teeth

|

2.0T*15X*1.4E*

8Z*22.23H

|

None Hole

K Slot

|

Allround

Guy

|

02

|

42

|

φ125

5''

|

|

Segmented

T-teeth

|

2.2T*10X*1.2E*

10Z*22.23H

|

None Hole

U Slot

|

Allround

Guy

|

02

|

|

43

|

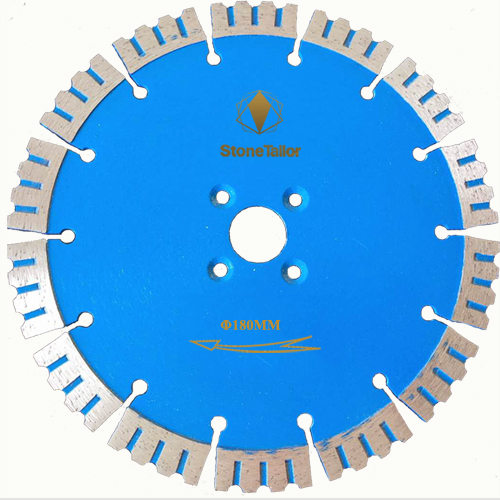

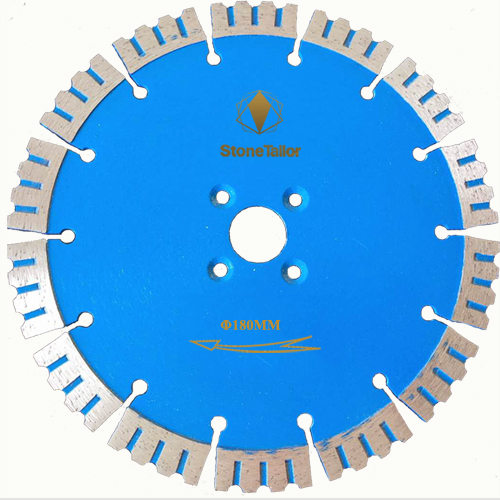

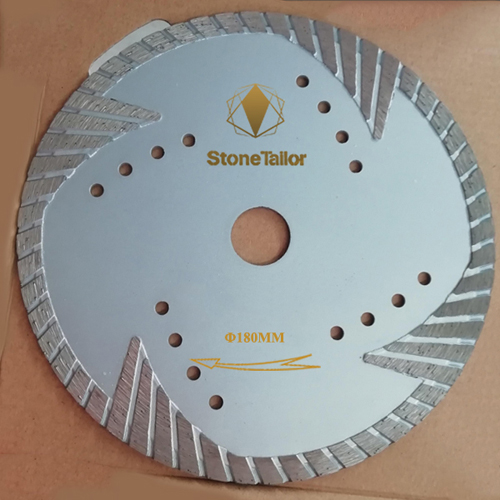

φ180

7''

|

|

Flower-teeth

|

2.4T*10X*1.6E*

14Z*22.23H

|

4 Holes

K Slot

|

Allround

Guy

|

02

|

|

44

|

φ180

7''

|

|

Triangular

-turbo

|

2.6T*10X*1.8E*

22.23H*Rim

|

12 Holes

Rim

|

Allround

Guy

|

02

|

|

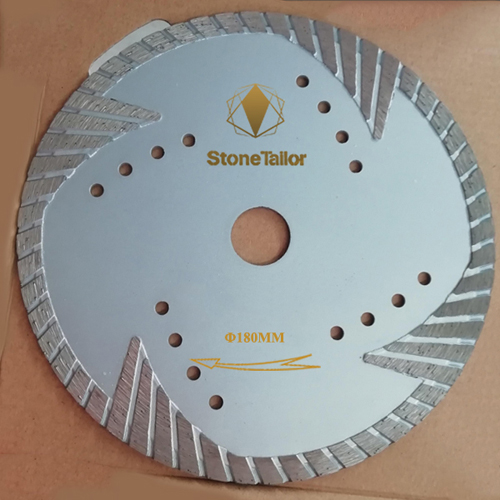

45

|

φ180

7''

|

|

Rimmed

T-teeth

|

2.6T*10X*1.8E*

22.23H*Rim

|

15 Holes

Rim

|

Allround

Guy

|

02

|

|

46

|

φ230

9''

|

|

Protective

-teeth

|

2.6T*10X*1.8E*

21Z*22.23H

|

None Hole

U Slot

|

Allround

Guy

|

02

|

|

47

|

φ230

9''

|

|

Triangular

-turbo

|

2.8T*10X*2.0E*

22.23H*Rim

|

30 Holes

Rim

|

Allround

Guy

|

02

|

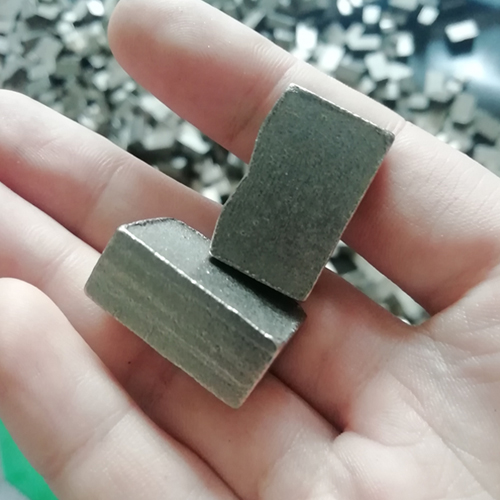

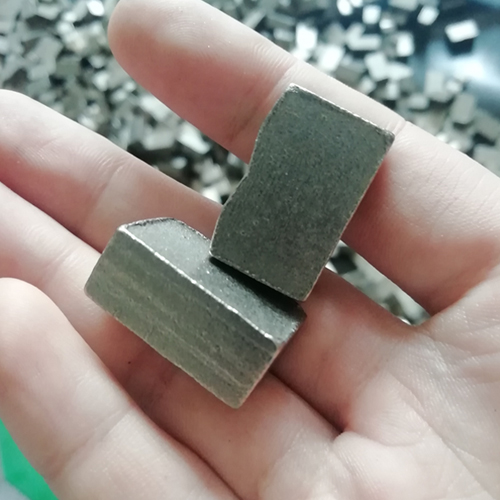

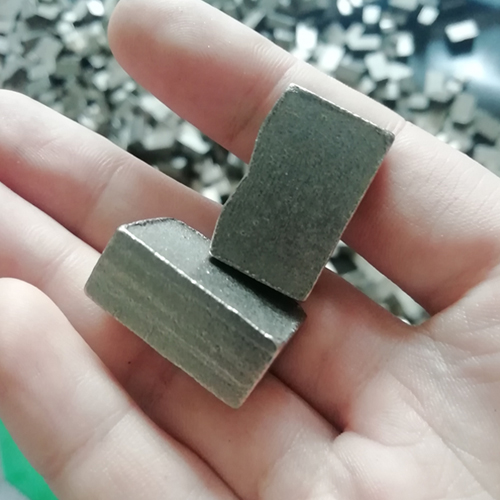

| Diamond Segments For Sandstone 05 |

| ITEM |

DIA.MM |

PICTURE |

THICKNESS |

SPEC.MM |

SEG. No |

SERIES |

CODE |

48

|

φ1600

64''

|

|

7.2

|

24*8.4/9.0*15/14

|

80 PCS

|

Allround

Guy

|

02

|

49

|

φ1600

64''

|

|

7.2

|

24*8.4/9.0*15/14

|

80 PCS

|

Allround

Guy

|

02

|

50

|

φ1600

64''

|

|

7.2

|

24*8.4/9.0*15 |

80 PCS

|

Allround

Guy

|

02

|

51

|

φ1600

64''

|

|

7.2

|

24*9.6/10.2*15/14 |

80 PCS

|

Allround

Guy

|

02

|

| Diamond Segments For Marble 06 |

| ITEM |

DIA.MM |

PICTURE |

THICKNESS |

SPEC.MM |

SEG. No |

SERIES |

CODE |

| 52 |

φ1600

64''

|

|

7.2/8

|

24*8.4/9.0*15 |

80 PCS

|

Allround

Guy

|

02

|

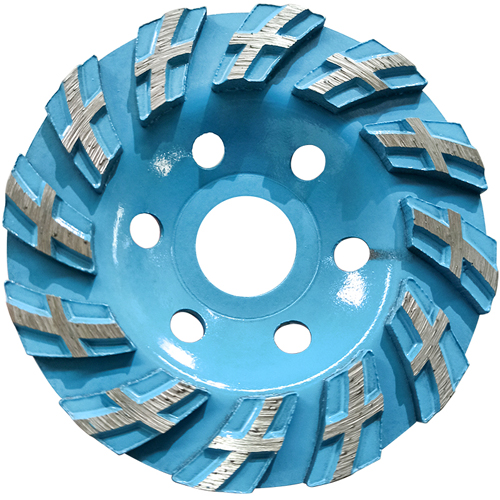

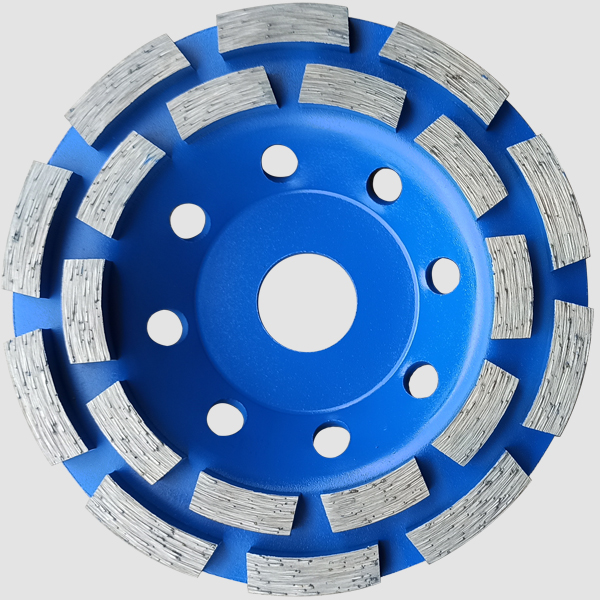

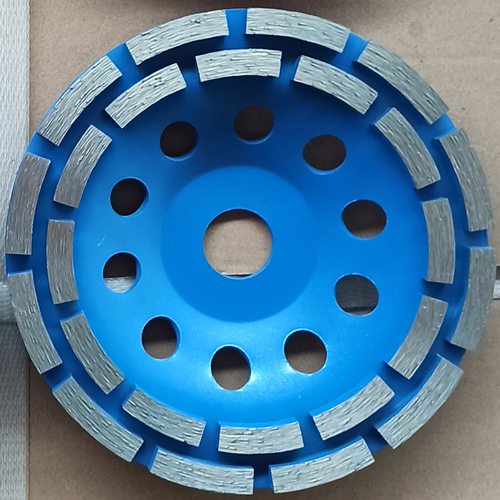

| For Cup Grinding Wheel 07 |

| ITEM |

DIA.MM |

PICTURE |

TYPE |

SPEC.MM |

HOLES/SLOT |

SERIES |

CODE |

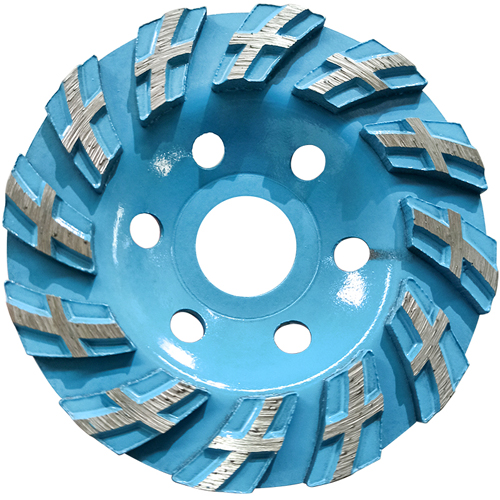

53

|

φ100

4''

|

|

Cross-teeth

|

5.7*12*20/22.23

with Rings

|

Cross-teeth

Seg./11

|

Allround

Guy

|

02

|

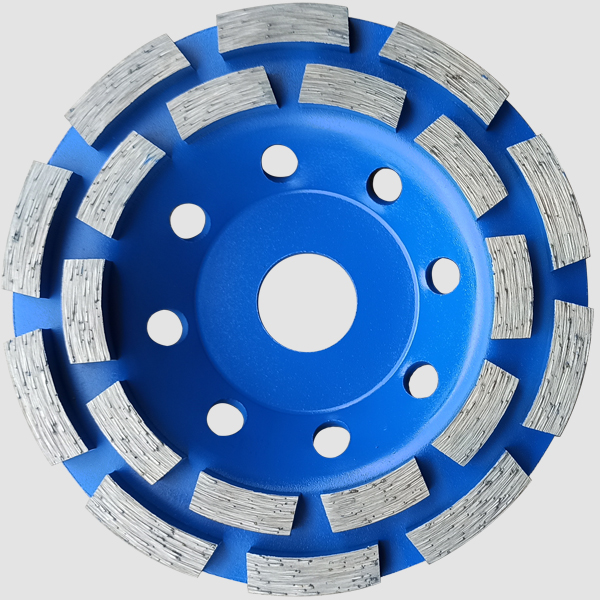

54

|

φ100

4''

|

|

Double-row

|

7*(8*2)

*22.23

|

Double-row

Seg./8*2

|

Allround

Guy

|

02

|

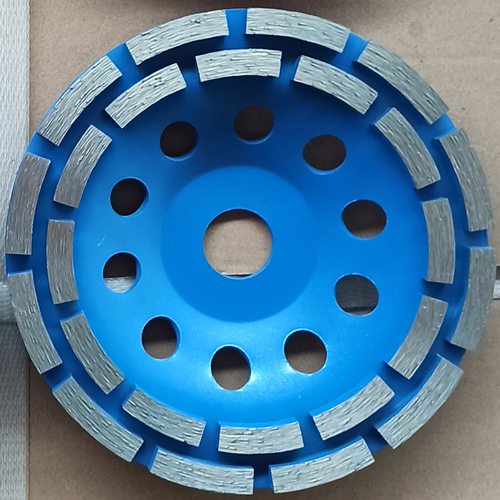

55

|

φ115

4.6''

|

|

Double-row

|

7*(9*2)

*22.23

|

Double-row

Seg./9*2

|

Allround

Guy

|

02

|

56

|

φ125

5''

|

|

Double-row

|

7*(10*2)

*22.23

|

Double-row

Seg./10*2

|

Allround

Guy

|

02

|

57

|

φ150

6''

|

|

Double-row

|

7*(12*2)

*22.23

|

Double-row

Seg./12*2

|

Allround

Guy

|

02

|

58

|

φ180

7''

|

|

Double-row

|

7*(12*2)

*22.23

|

Double-row

Seg./12*2

|

Allround

Guy

|

02

|

59

|

φ100

4''

|

|

Aluminuim

|

7.5*24

*M14

|

M14

&5/8-1

|

Allround

Guy

|

02

|

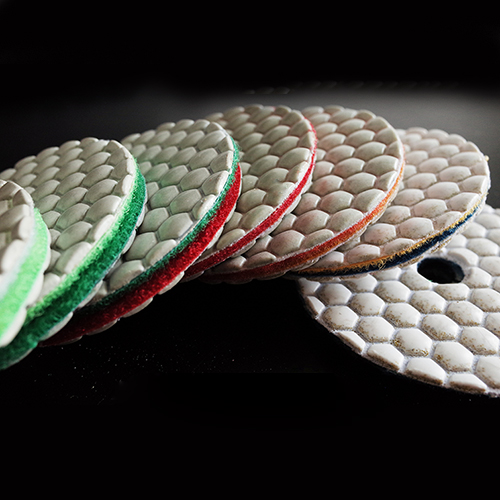

| For Polishing Pad 08 |

| ITEM |

DIA.MM |

PICTURE |

TYPE |

GRITS |

THICKNESS |

SERIES |

CODE |

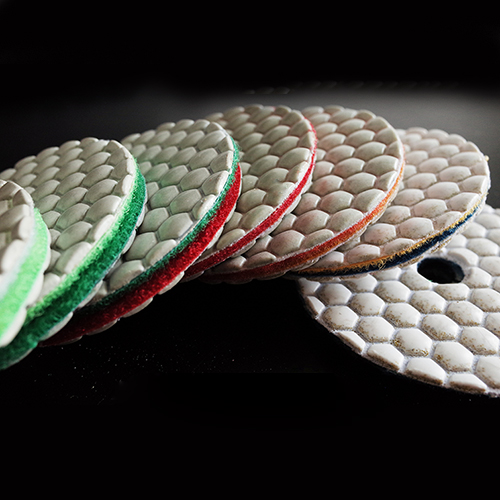

| 60 |

φ100

4''

|

|

Convex-tooth

Dry

|

50# 100# 200#

400# 800# 1500#

3000# Buff#

|

2.5MM

|

Allround

Guy

|

02

|

61

|

φ100

4''

|

|

Flat-tooth

Dry

|

50# 100# 200#

400# 800# 1500#

3000# Buff#

|

2.5MM

|

Allround

Guy

|

02

|

62

|

φ100

4''

|

|

Flat-tooth

Wet

|

50# 100# 200#

400# 800# 1500#

3000# Buff#

|

3MM

|

Allround

Guy

|

02

|

.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

- comments in total【Write a Review】Customer Reviews