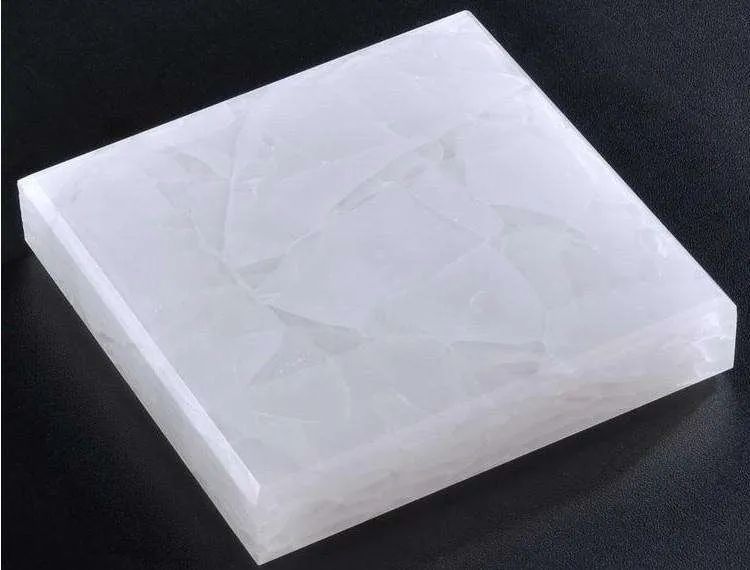

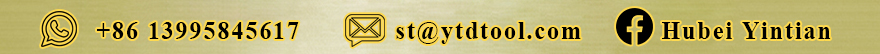

Marble is a kind of carbonate stone.Because of the plentiful beautiful natural colors and less radiation,it’s taken as the perfect stone for interior decoration.And it has the characteristics of good looking and rich patterns,mild colors, which will bring high-grade and magnificent decorative effects.Therefore, the higher requirements are put forward for the processing of marble stones.Specially for the hard marble ,there shall be no the phenomenon of chipping ,breaking during cutting.In order to produce the high-quality valuable marble stones products,it is necessary to use high-quality marble saw blades of processing.

.jpg)

But it’s not an easy thing to find a matching marble blade to cut super-hard marble stones.For general marble blades,it’s so hard to achieve a satisfactory cutting outcome.Some of the experienced marble blade dealers often concern about an issue,how can they make their customers satisfied?Because they usually get the complaints from the customers that their marble blades have a relative short lifespan or not sharp enough.Even,there are some phenomenons of chipping ,breaking or edge when cutting,which probably cause severe losses on their cost and reputation in the field.Looking for a kind of top quality marble blade that will satisfy customers has always been their goal.

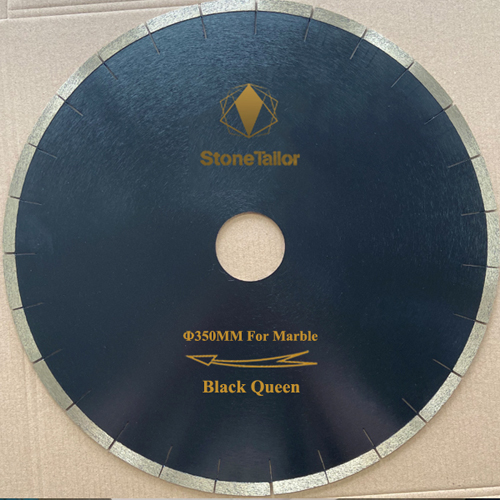

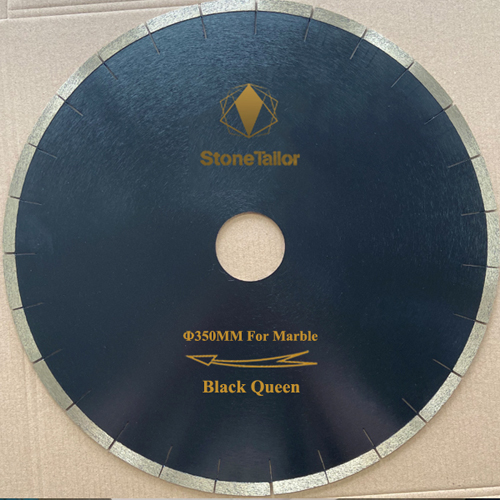

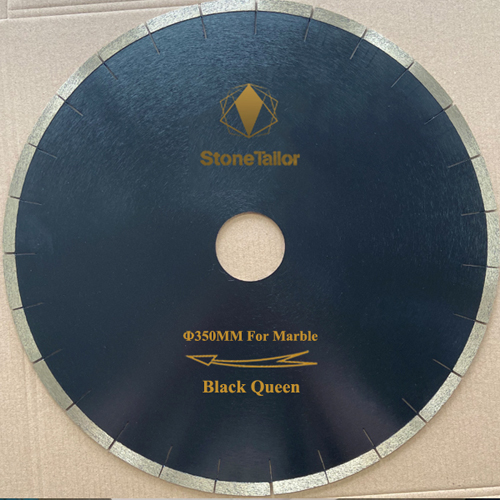

Hubei YINTIAN Diamond Tools has developed a top-quality marble blade,Black Queen,which is specializing in cutting the valuable & uncommon marbles and ultra-hard & hard-brittle artificial stones.This marble blade can help reduce all your worries on marble cutting.

.jpg)

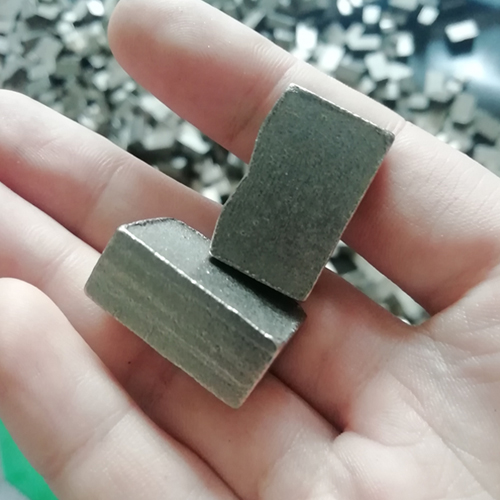

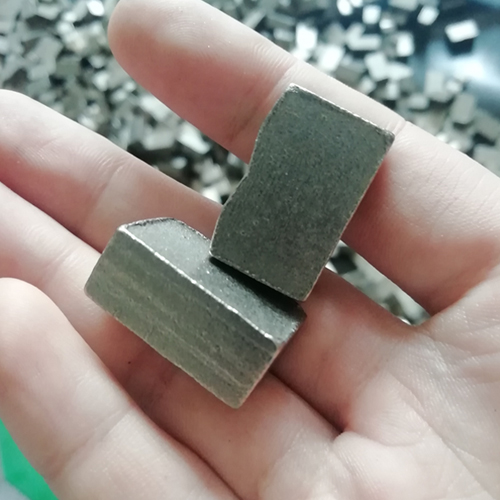

Black Queen cutting blade is a kind of top-level marble blade with high sharpness and precision,and it can cut out marble slabs an straight lines absolutely without chipping,breaking.Fast cutting super-hard marbles is as smooth as cutting mud,and our customers always are amazed by Black Queen's sharpness,and say “What a surprise, how sharp!It feels so good to cut,even if our marble is so hard!”Its high feeding speed make marble slabs pretty smooth after processing.Fine cutting quality guarantee stable performance without cracks,burr or vibration for cutting any marbles.Its segments are compact and dense ,high temperature resistance, good toughness, high welding strength ,which can cut out some marble slabs to make them a perfect combination after laying.

.jpg)

At the same time,YINTIAN Diamond saw blade for Marble can have a good balance between sharpness and wear resistance in one diamond saw blade.When cutting hard marble fast and smoothly,it can bring out a good chip removal and heat dissipation performance.Its longer lifespan with high wear resistance not only makes full use of cutting performance but also can prolong the lifespan of segments.

In addition,the high quality of Black queen Diamond disc for marble is also shown in its beautiful appearance.The attractive and exquisite look also has been recognized and praised by many customers.They left good reviews repeatedly.

In the face of this compliments from customers, every employee of our Hubei YINTIAN is really happy.We have been committed to meeting customer needs and provide our customer with high quality marble blades. Every customer's affirmation is our greatest return.

YINTIAN Black Queen Marble cutting blades are of top quality, high performance and good market reputation,it can always give you desired cutting outcomes.

|

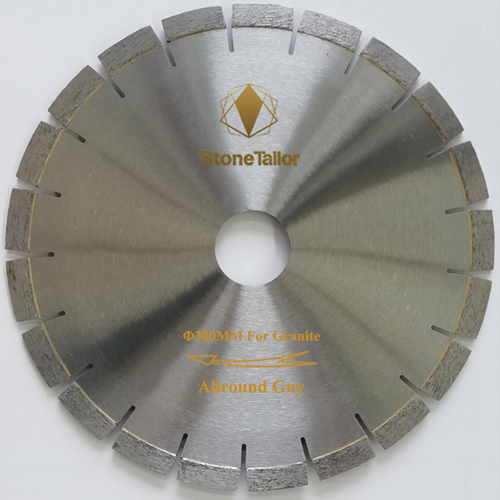

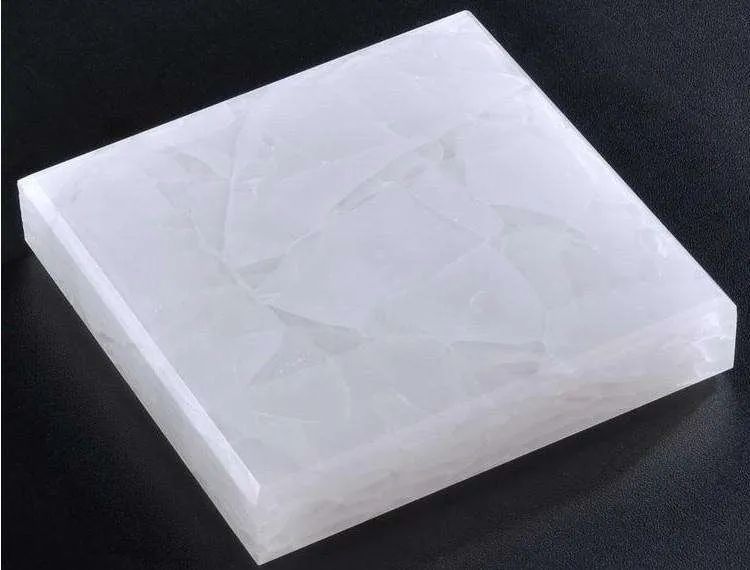

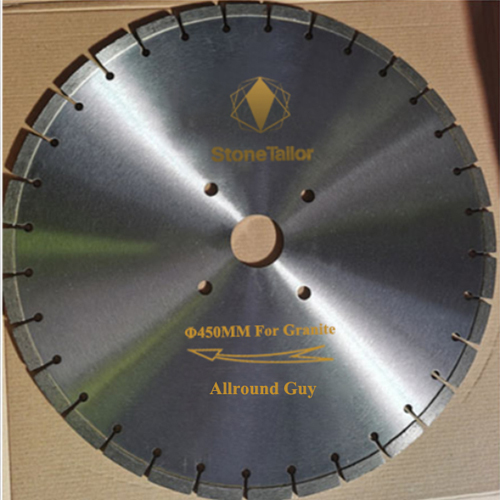

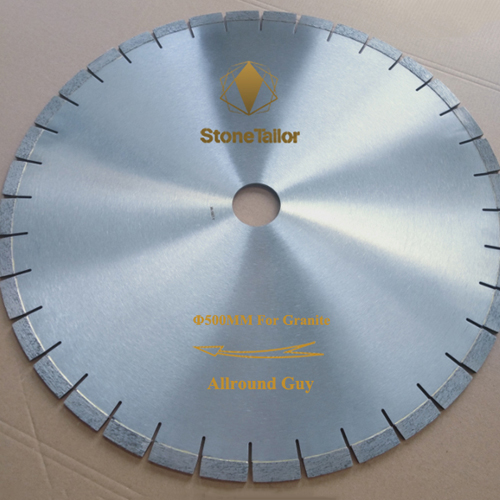

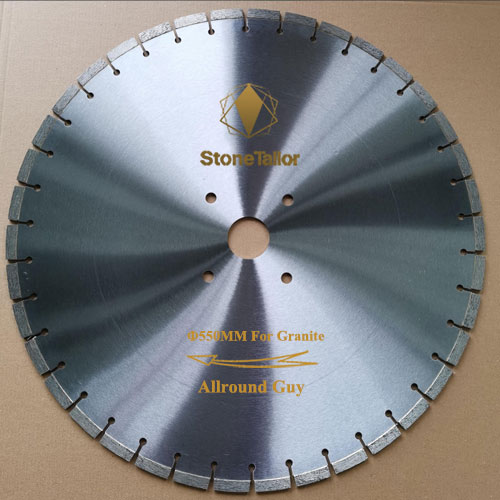

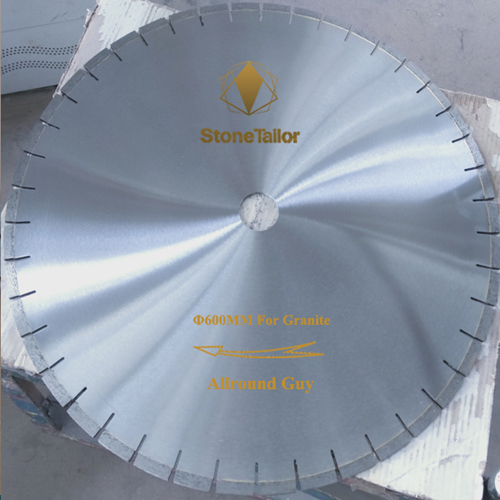

Diamond Saw Blade For Granite 01

|

| ITEM |

DIA.MM |

PICTURE |

TYPE |

SPEC.MM |

HOLES/SLOT |

SERIES |

CODE |

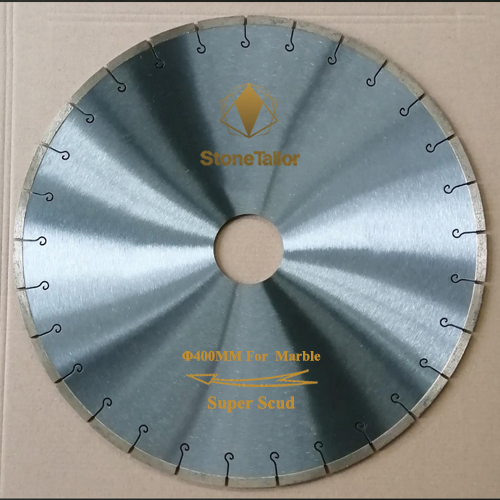

1

|

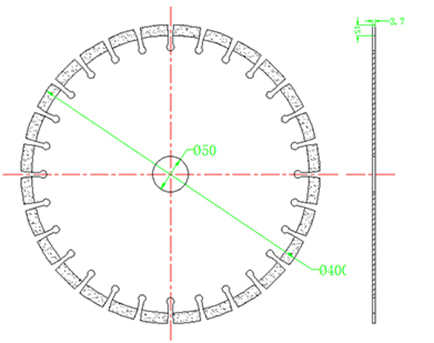

φ300

12”

|

|

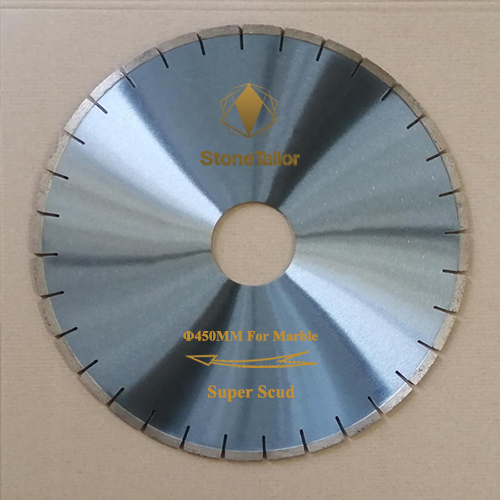

Normal

Silent

|

(40*3.2*15)

*(2.4*21T*50) |

None Hole

U Slot

|

Allround

Guy

|

02

|

2

|

φ350

14''

|

|

Normal

Silent

|

(40*3.3*15)

*(2.4*24T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

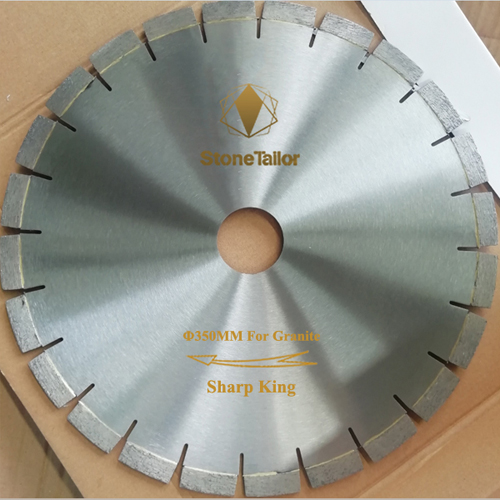

3

|

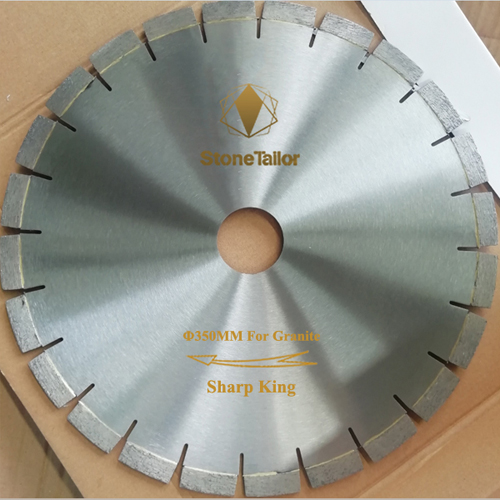

φ350

14''

|

|

Normal

Silent

|

(40*3.3*15)

*(2.4*24T*50)

|

None Hole

U Slot

|

Sharp

King

|

05

|

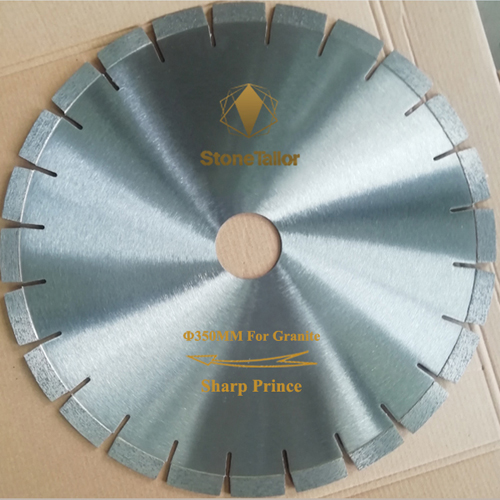

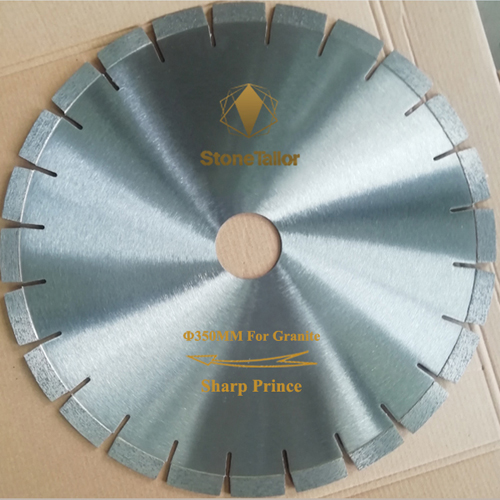

4

|

φ350

14''

|

|

Normal

Silent

|

(40*3.3*15)

*(2.4*24T*50)

|

None Hole

U Slot

|

Sharp

Prince

|

06

|

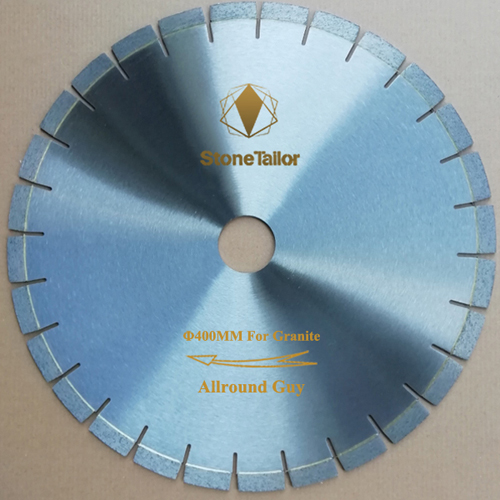

5

|

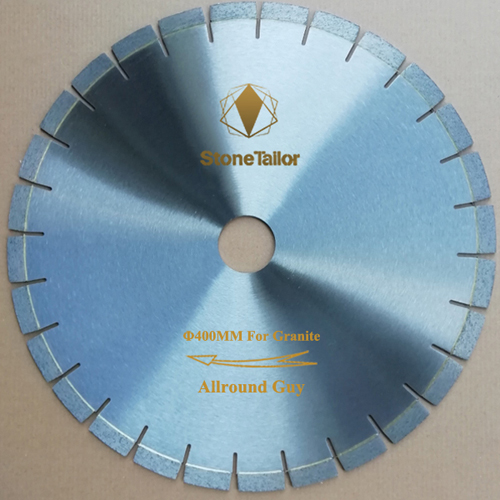

φ400

16''

|

|

Normal

Silent

|

(40*3.6*15)

*(2.8*28T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

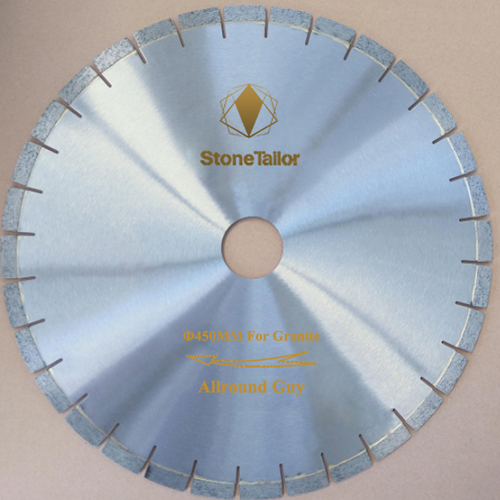

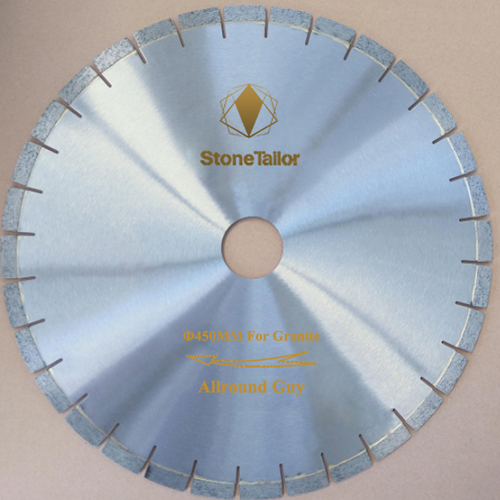

6

|

φ450

18''

|

|

Normal

Silent

|

(40*4.2*12)

*(3.0*32T*50)

|

None Hole

U Slot

|

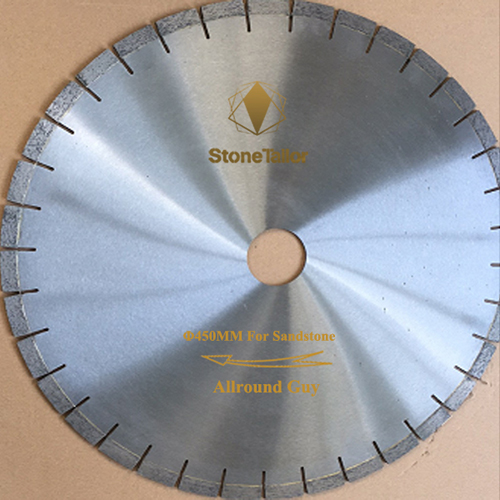

Allround

Guy

|

02

|

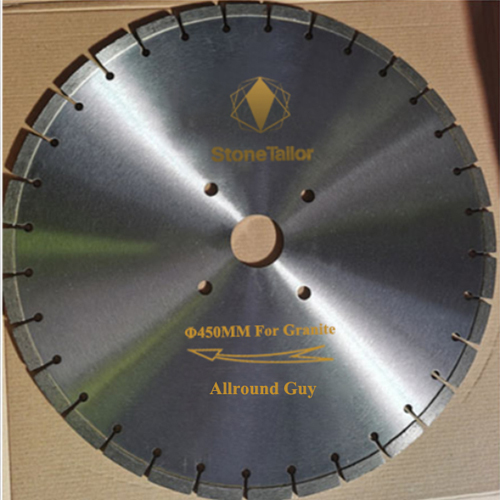

7

|

φ450

18''

|

|

Normal

Silent

|

(40*4.2*15)

*(3.0*32T*50)

|

4 Holes

U Slot

|

Allround

Guy

|

02

|

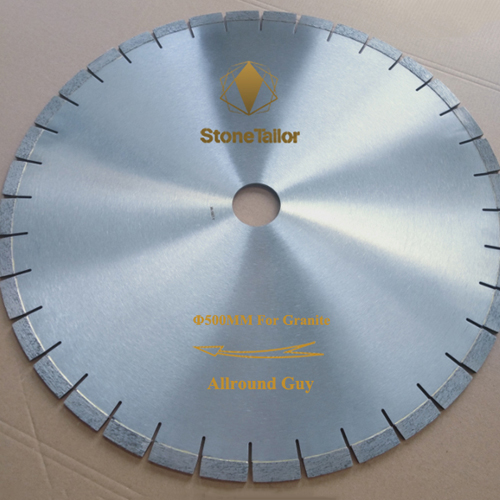

8

|

φ500

20''

|

|

Normal

Silent

|

(40*4.2*15)

*(3.0*36T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

9

|

φ500

20''

|

|

Normal

Silent

|

(40*4.2*12)

*(3.0*36T*50)

|

None Hole

U Slot

|

Practical

Guy

|

09

|

10

|

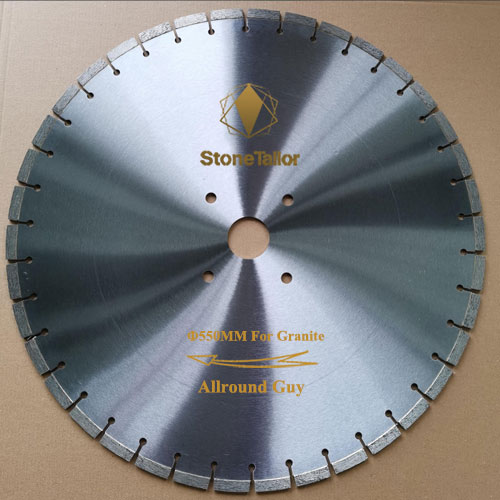

φ550

22''

|

|

Normal

Silent

|

(40*4.3*12)

*(3.2*38T*50)

|

None Hole

K Slot

|

Allround

Guy

|

09

|

11

|

φ600

24''

|

|

Normal

Silent

|

(40*4.8*12)

*(3.6*42T*50)

|

None Hole

U Slot

|

Practical

Guy

|

09

|

12

|

φ600

24''

|

|

Normal

Silent

|

(40*4.8*15)

*(3.6*42T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

13

|

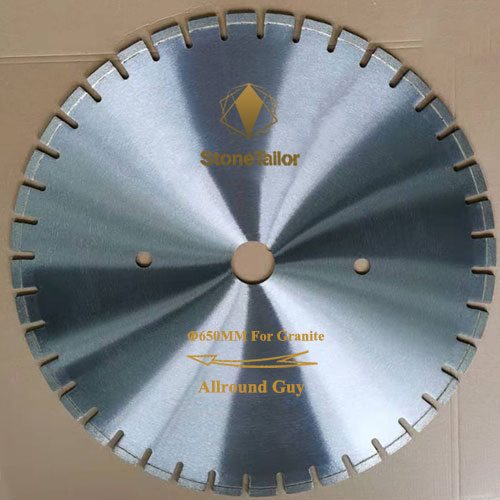

φ650

26''

|

|

Normal

Silent

|

(40*4.8*12)

*(3.6*40T*50)

|

2 Holes

U Slot

|

Allround

Guy

|

02

|

14

|

φ700

28''

|

|

Normal

Silent

|

(40*5.5*15)

*(4.0*40T*50)

|

4 Holes

U Slot

|

Allround

Guy

|

02

|

15

|

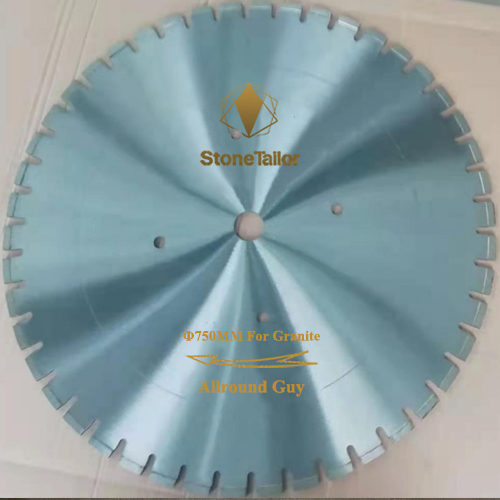

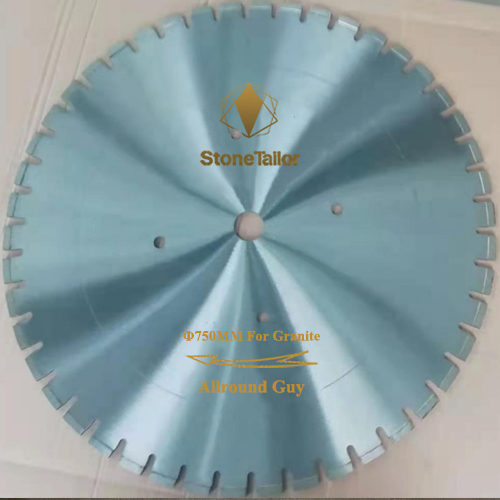

φ750

30''

|

|

Normal

Silent

|

(40*5.5*12)

*(4.0*46T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

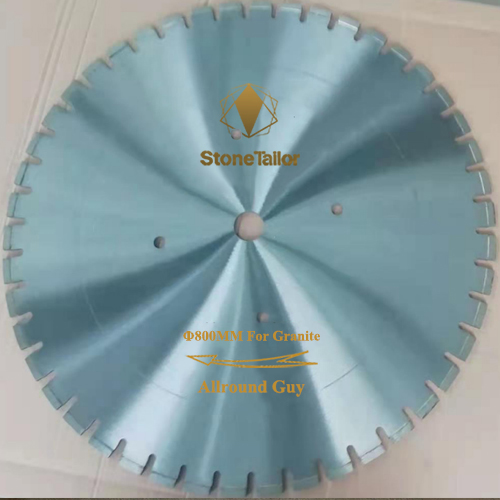

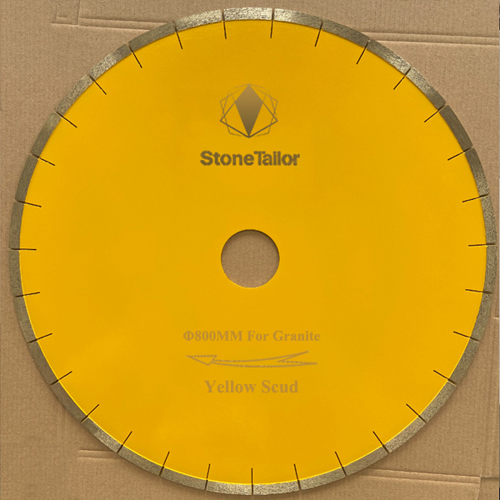

16

|

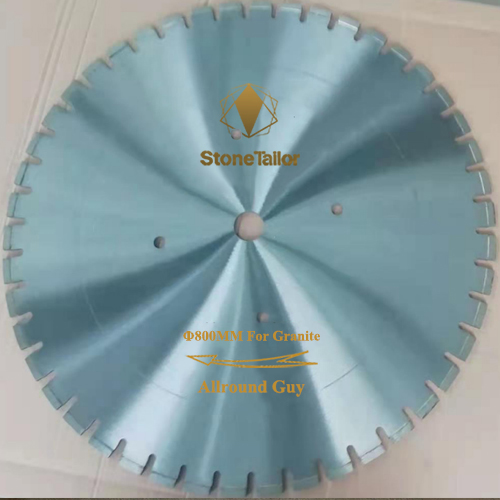

φ800

32''

|

|

Normal

Silent

|

(40*6.0*12)

*(4.5*46T*50)

|

4 Holes

U Slot

|

Allround

Guy

|

02

|

| Diamond Saw Blade For Marble 02 |

| ITEM |

DIA.MM |

PICTURE |

TYPE |

SPEC.MM |

HOLES/SLOT |

SERIES |

CODE |

17

|

φ300

12''

|

|

Normal

Silent

|

(40/39*2.7*8)

*(2.2*23T*50)

|

None Hole

Musical Slot

|

White

Angel

|

12

|

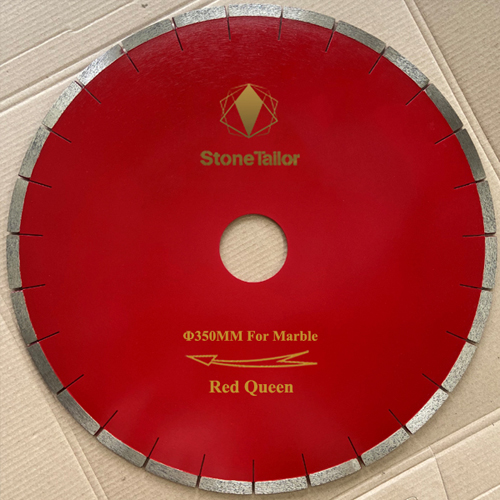

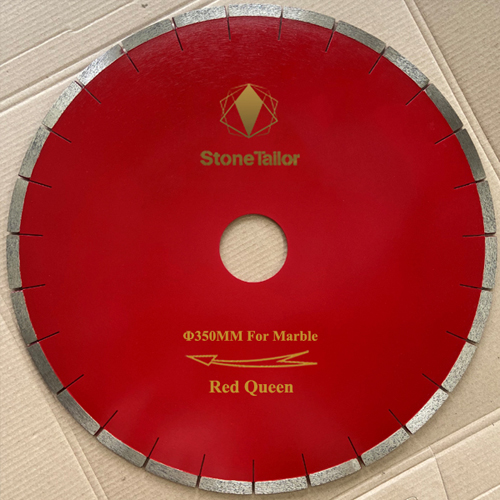

| 18 |

φ350

14''

|

|

Normal

Silent

|

(39/37.8*2.8*9)

*(2.3*27T*50)

|

None Hole

U Slot

|

Red

Queen

|

11

|

| 19 |

φ350

14''

|

|

Normal

Silent

|

(39/37.8*2.8*9)

*(2.3*27T*50)

|

None Hole

U Slot

|

Black

Queen

|

10 |

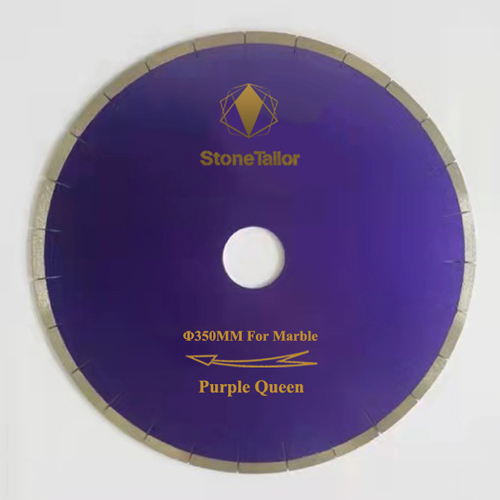

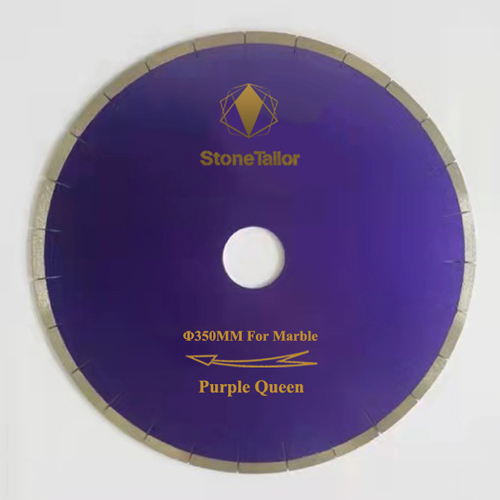

20

|

φ350

14''

|

|

Normal

Silent

|

(39/37.8*2.8*9)

*(2.3*27T*50)

|

None Hole

U Slot

|

Purple

Queen

|

10

|

21

|

φ350

14''

|

|

Normal

Silent

|

(40/39*2.7*8)

*(2.3*27T*50)

|

None Hole

Musical Slot

|

White

Angel

|

12

|

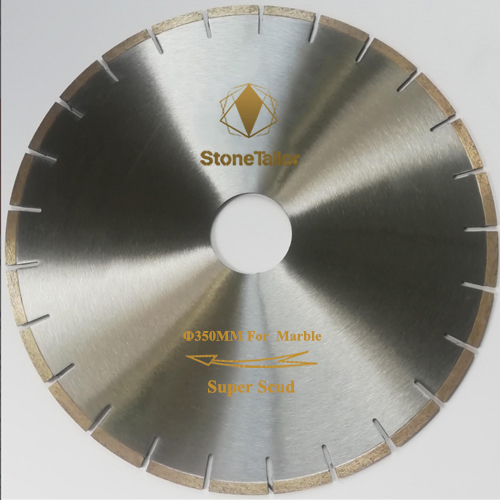

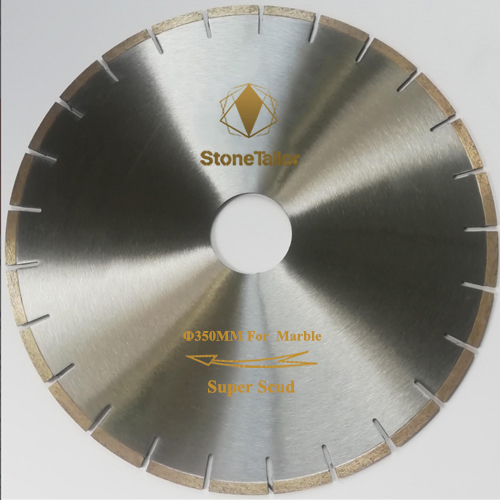

22

|

φ350

14''

|

|

Normal

Silent

|

(40/39*2.9*8)

*(2.3*27T*50)

|

None Hole

U Slot

|

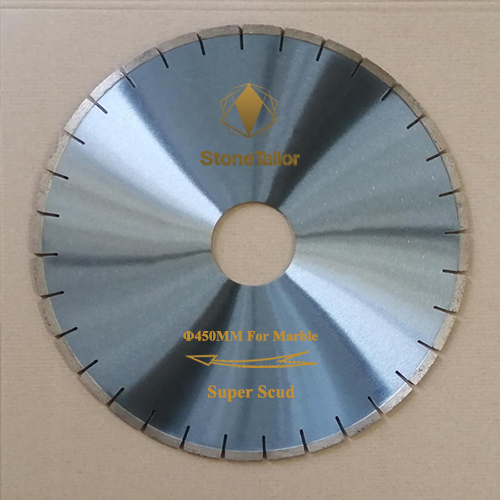

Super

Scud

|

13

|

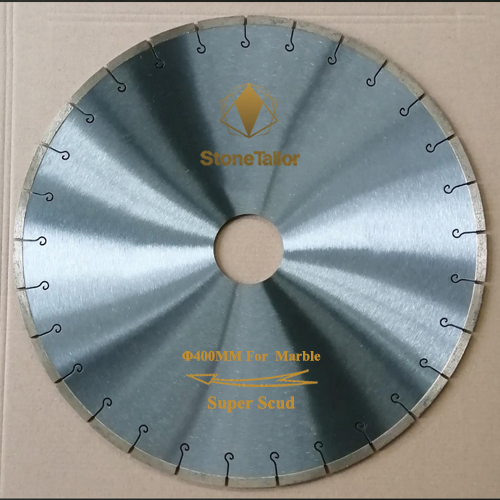

23

|

φ400

16''

|

|

Normal

Silent

|

(39/37.8*3.4*9)

*(2.6*31T*50)

|

None Hole

U Slot

|

Super

Scud

|

13

|

24

|

φ400

16''

|

|

Normal

Silent

|

(39/37.8*3.4*9)

*(2.6*31T*50)

|

None Hole

U Slot

|

Red

Queen

|

11

|

25

|

φ400

16''

|

|

Normal

Silent

|

(41.5/40*2.9*8)

*(2.2*30T*50)

|

None Hole

Musical Slot

|

White

Angel

|

12

|

26

|

φ350

14''

|

|

Normal

Silent

|

(43/41.5*2.9*8)

*(2.2*25T*60)

|

None Hole

U Slot

|

Super

Scud

|

13

|

27

|

φ400

16''

|

|

Normal

Silent

|

(40*3.6*10)

*(2.8*28T*60)

|

None Hole

U Slot

|

Super

Scud

|

13

|

28

|

φ450

18''

|

|

Normal

Silent

|

(40*4.2*10)

*(3.0*32T*90/60)

|

None Hole

U Slot

|

Super

Scud

|

13

|

29

|

φ500

20''

|

|

Normal

Silent

|

(40*4.3*10)

*(3.0*36T*50)

|

None Hole

U Slot

|

Scud |

14

|

30

|

φ500

20''

|

|

Normal

Silent

|

(40*4.2*10)

*(3.0*36T*90/60)

|

None Hole

U Slot

|

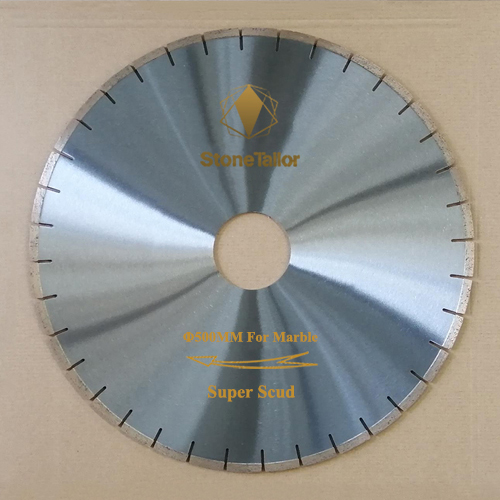

Super

Scud

|

13

|

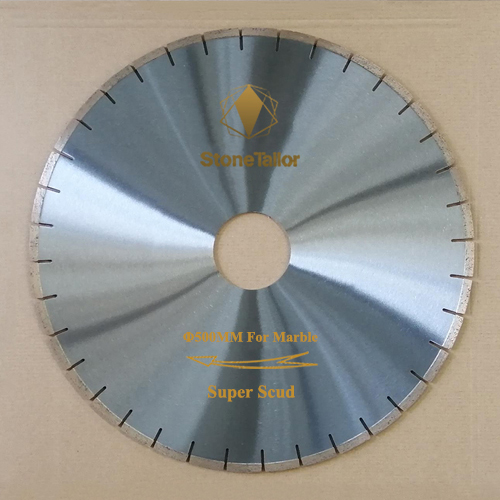

| 31 |

φ600

24''

|

|

Normal

Silent

|

(40*4.8*10)

*(3.6*42T*90/60)

|

None Hole

U Slot

|

Super

Scud

|

13

|

32

|

φ650

26''

|

|

Normal

Silent

|

(40*4.8*10)

*(3.6*40T*60)

|

None Hole

U Slot

|

Super

Scud

|

13

|

33

|

φ700

28''

|

|

Normal

Silent

|

(38*5.2*10)

*(4.0*40T*60)

|

None Hole

U Slot

|

Super

Scud

|

13

|

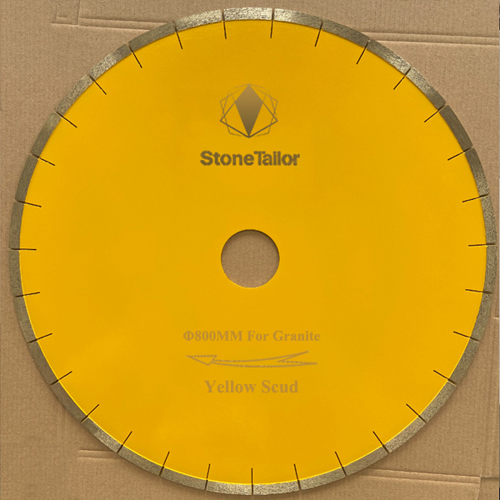

34

|

φ800

32''

|

|

Normal

Silent

|

(38*6.0*10)

*(4.5*46T*60)

|

None Hole

U Slot

|

Super

Scud

|

13

|

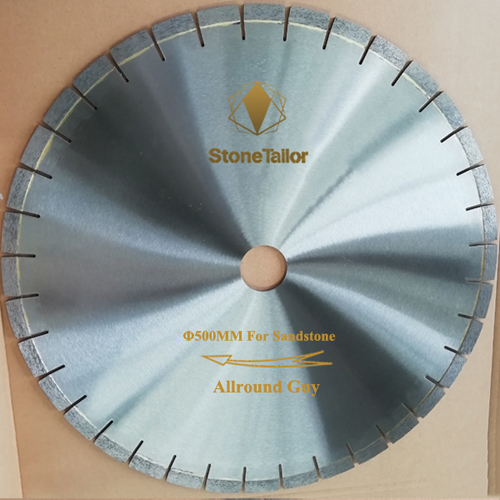

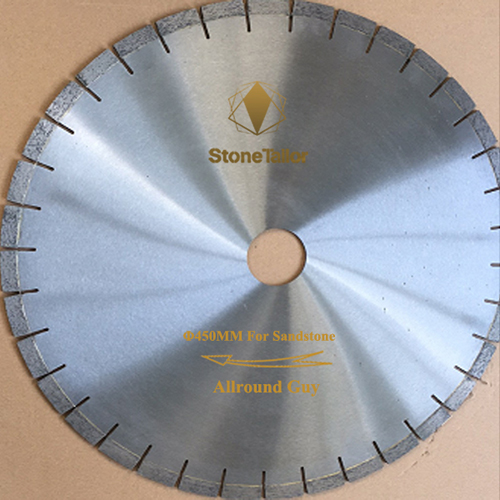

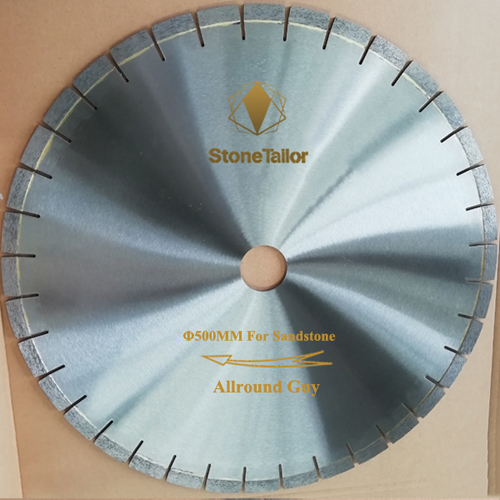

| Diamond Saw Blade For Sandstone 03 |

| ITEM |

DIA.MM |

PICTURE |

TYPE |

SPEC.MM |

HOLES/SLOT |

SERIES |

CODE |

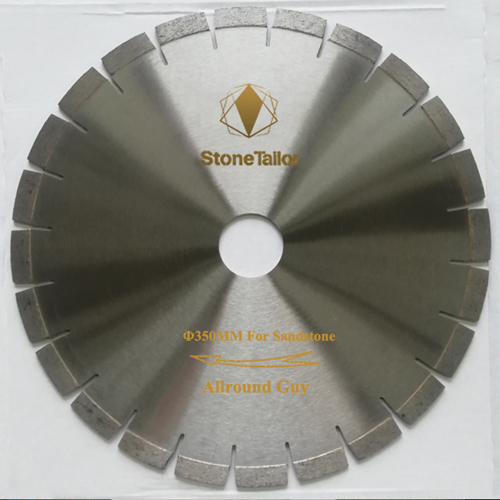

35

|

φ350

14''

|

|

Normal

Silent

|

(40*3.3*15)

*(2.4*24T*50)

|

None Hole

U Slot

|

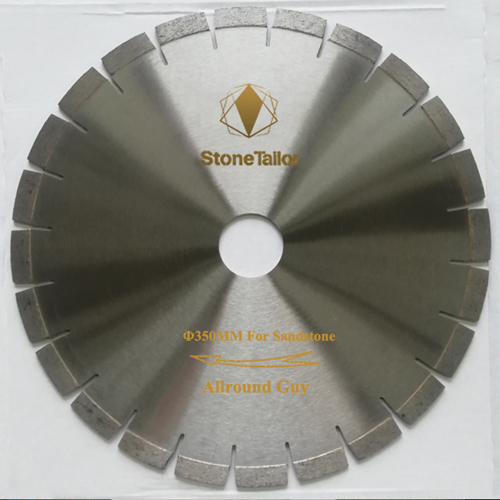

Allround

Guy

|

02

|

36

|

φ400

16''

|

|

Normal

Silent

|

(40*3.8*15)

*(2.8*28T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

37

|

φ450

18''

|

|

Normal

Silent

|

(40*4.0*15)

*(3.0*32T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

38

|

φ500

20''

|

|

Normal

Silent

|

(40*4.2*15)

*(3.0*36T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

39

|

φ600

24''

|

|

Normal

Silent

|

(40*4.5*15)

*(3.6*42T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

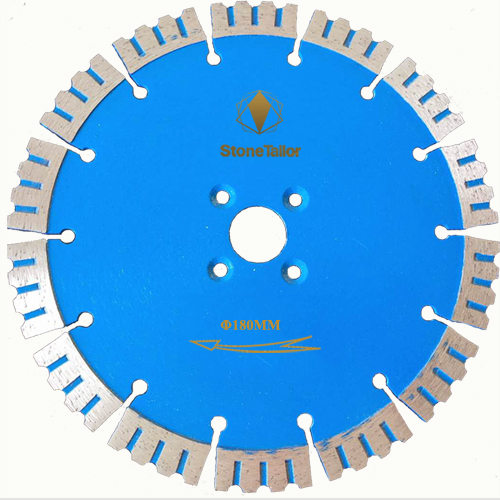

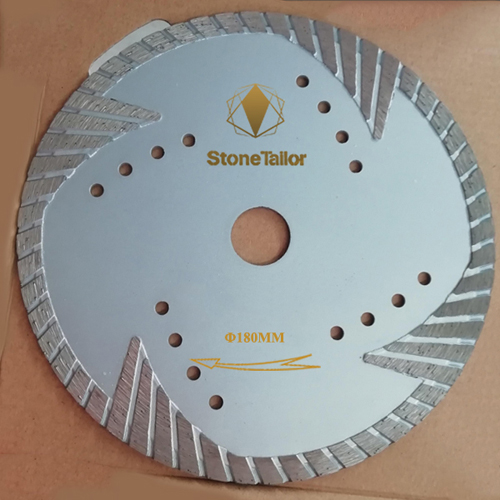

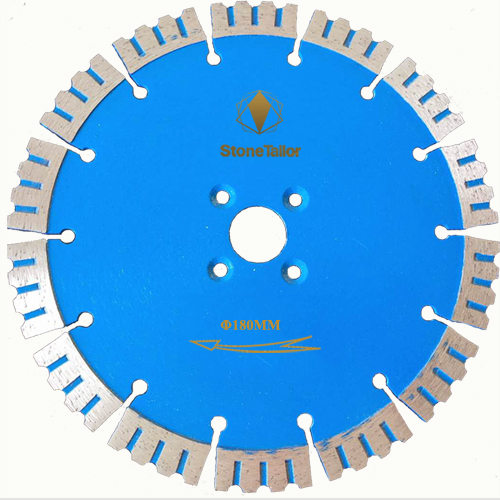

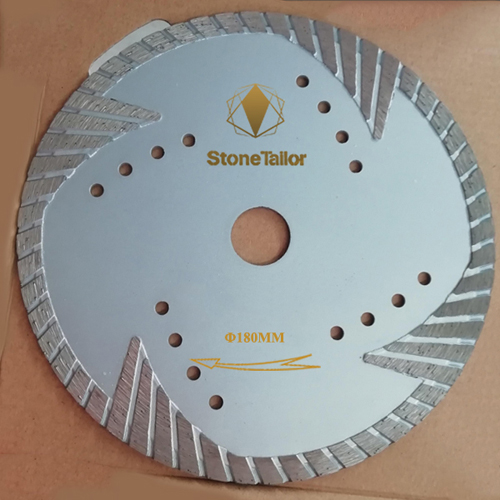

| Diamond Saw Blade For Hot-press 04 |

| ITEM |

DIA.MM |

PICTURE |

TYPE |

SPEC.MM |

HOLES/SLOT |

SERIES |

CODE |

40

|

φ110

4.5''

|

|

Protective

-teeth

|

2.0T*10X*1.2E*

9Z*22.23H

|

None Hole

U Slot

|

Allround

Guy

|

02

|

| 41 |

φ115

4.5''

|

|

Protective

-teeth

|

2.0T*15X*1.4E*

8Z*22.23H

|

None Hole

K Slot

|

Allround

Guy

|

02

|

42

|

φ125

5''

|

|

Segmented

T-teeth

|

2.2T*10X*1.2E*

10Z*22.23H

|

None Hole

U Slot

|

Allround

Guy

|

02

|

|

43

|

φ180

7''

|

|

Flower-teeth

|

2.4T*10X*1.6E*

14Z*22.23H

|

4 Holes

K Slot

|

Allround

Guy

|

02

|

|

44

|

φ180

7''

|

|

Triangular

-turbo

|

2.6T*10X*1.8E*

22.23H*Rim

|

12 Holes

Rim

|

Allround

Guy

|

02

|

|

45

|

φ180

7''

|

|

Rimmed

T-teeth

|

2.6T*10X*1.8E*

22.23H*Rim

|

15 Holes

Rim

|

Allround

Guy

|

02

|

|

46

|

φ230

9''

|

|

Protective

-teeth

|

2.6T*10X*1.8E*

21Z*22.23H

|

None Hole

U Slot

|

Allround

Guy

|

02

|

|

47

|

φ230

9''

|

|

Triangular

-turbo

|

2.8T*10X*2.0E*

22.23H*Rim

|

30 Holes

Rim

|

Allround

Guy

|

02

|

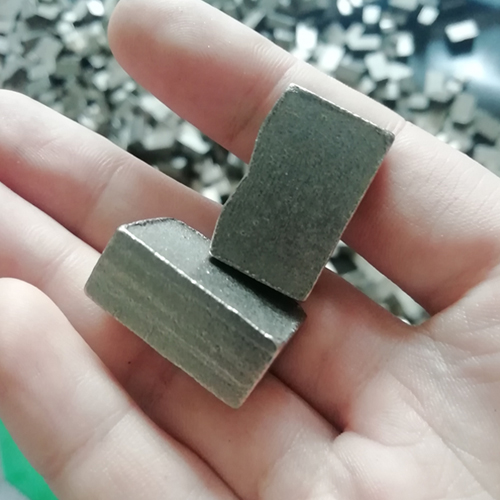

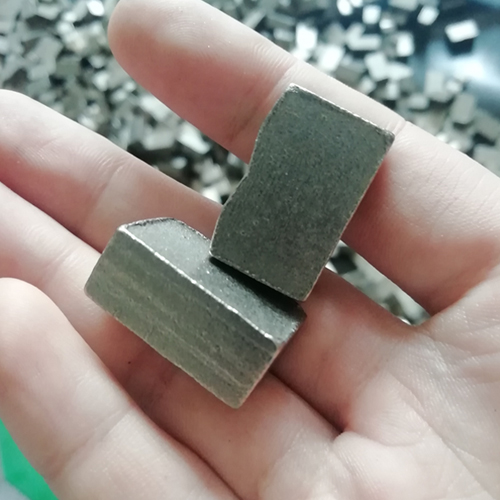

| Diamond Segments For Sandstone 05 |

| ITEM |

DIA.MM |

PICTURE |

THICKNESS |

SPEC.MM |

SEG. No |

SERIES |

CODE |

48

|

φ1600

64''

|

|

7.2

|

24*8.4/9.0*15/14

|

80 PCS

|

Allround

Guy

|

02

|

49

|

φ1600

64''

|

|

7.2

|

24*8.4/9.0*15/14

|

80 PCS

|

Allround

Guy

|

02

|

50

|

φ1600

64''

|

|

7.2

|

24*8.4/9.0*15 |

80 PCS

|

Allround

Guy

|

02

|

51

|

φ1600

64''

|

|

7.2

|

24*9.6/10.2*15/14 |

80 PCS

|

Allround

Guy

|

02

|

| Diamond Segments For Marble 06 |

| ITEM |

DIA.MM |

PICTURE |

THICKNESS |

SPEC.MM |

SEG. No |

SERIES |

CODE |

| 52 |

φ1600

64''

|

|

7.2/8

|

24*8.4/9.0*15 |

80 PCS

|

Allround

Guy

|

02

|

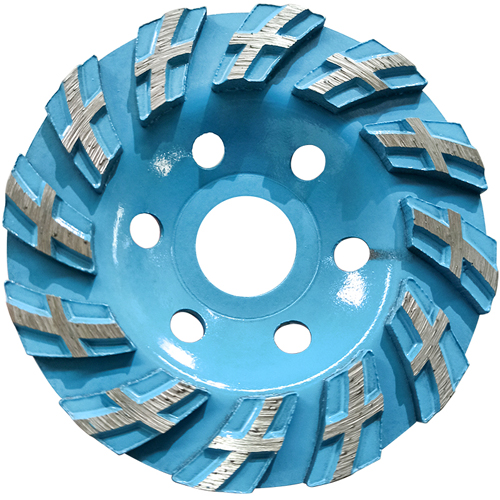

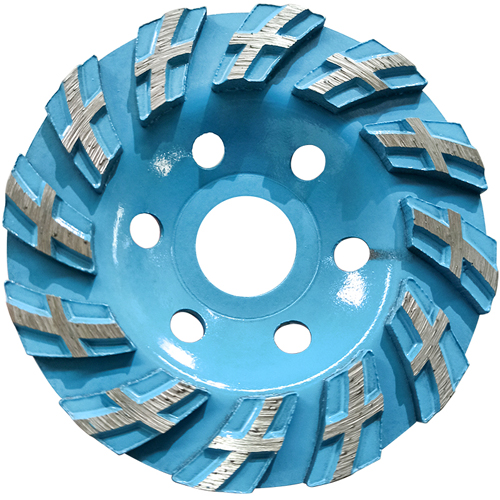

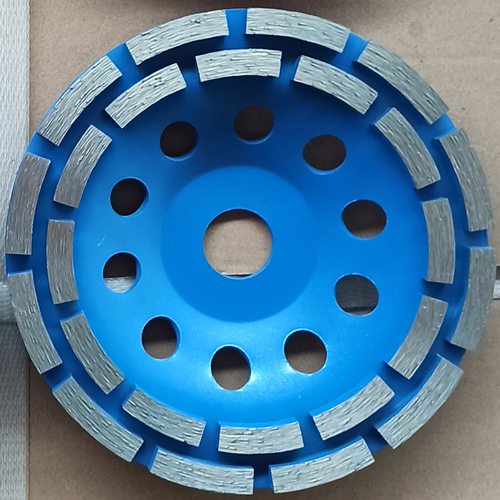

| For Cup Grinding Wheel 07 |

| ITEM |

DIA.MM |

PICTURE |

TYPE |

SPEC.MM |

HOLES/SLOT |

SERIES |

CODE |

53

|

φ100

4''

|

|

Cross-teeth

|

5.7*12*20/22.23

with Rings

|

Cross-teeth

Seg./11

|

Allround

Guy

|

02

|

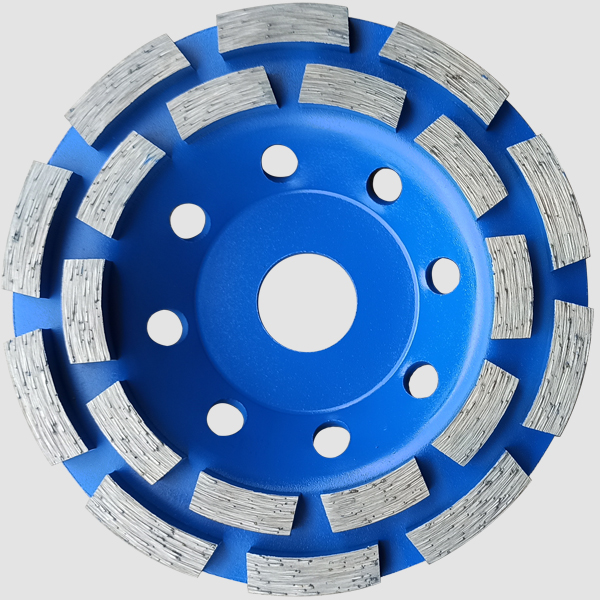

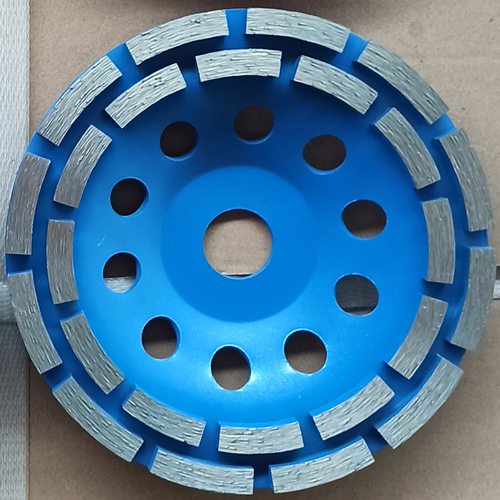

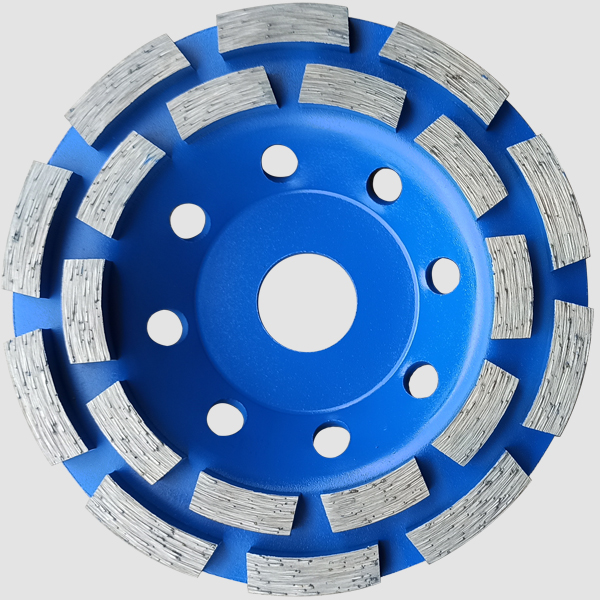

54

|

φ100

4''

|

|

Double-row

|

7*(8*2)

*22.23

|

Double-row

Seg./8*2

|

Allround

Guy

|

02

|

55

|

φ115

4.6''

|

|

Double-row

|

7*(9*2)

*22.23

|

Double-row

Seg./9*2

|

Allround

Guy

|

02

|

56

|

φ125

5''

|

|

Double-row

|

7*(10*2)

*22.23

|

Double-row

Seg./10*2

|

Allround

Guy

|

02

|

57

|

φ150

6''

|

|

Double-row

|

7*(12*2)

*22.23

|

Double-row

Seg./12*2

|

Allround

Guy

|

02

|

58

|

φ180

7''

|

|

Double-row

|

7*(12*2)

*22.23

|

Double-row

Seg./12*2

|

Allround

Guy

|

02

|

59

|

φ100

4''

|

|

Aluminuim

|

7.5*24

*M14

|

M14

&5/8-1

|

Allround

Guy

|

02

|

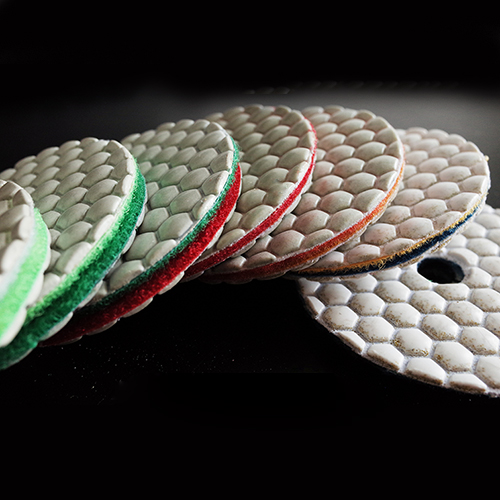

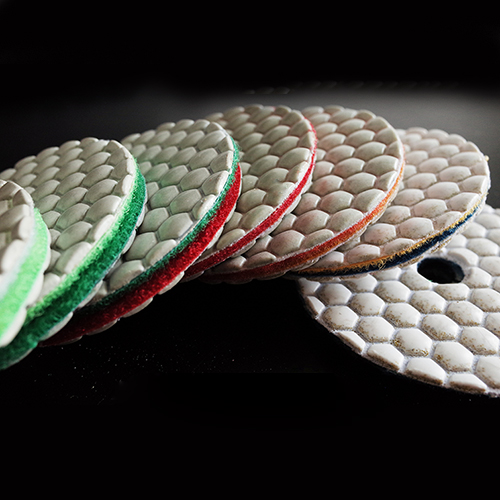

| For Polishing Pad 08 |

| ITEM |

DIA.MM |

PICTURE |

TYPE |

GRITS |

THICKNESS |

SERIES |

CODE |

| 60 |

φ100

4''

|

|

Convex-tooth

Dry

|

50# 100# 200#

400# 800# 1500#

3000# Buff#

|

2.5MM

|

Allround

Guy

|

02

|

61

|

φ100

4''

|

|

Flat-tooth

Dry

|

50# 100# 200#

400# 800# 1500#

3000# Buff#

|

2.5MM

|

Allround

Guy

|

02

|

62

|

φ100

4''

|

|

Flat-tooth

Wet

|

50# 100# 200#

400# 800# 1500#

3000# Buff#

|

3MM

|

Allround

Guy

|

02

|

-

Marble Blades Cutting Slabs

-

Marble Blades Cutting Slabs

-

Marble Blades Cutting Slabs

Saw Blades Cut

the Marble Stone use for Stairs

-

Saw Blades Cut

the Marble Stone use for Floor tile

-

Saw Blades Cut

the Marble Stone use for exterior wall

-

Saw Blades Cut

the Marble Stone Cabinet board

.jpg)

-

The first type of clients:The first type of clients:The structure of the stone that they are processing is complex.for example,for example,They cut varieties granite plate with larger quartz particles,high sand content,close coexists and high abrasiveness ,thus the segment easily get chipping in the cutting process.so They must choose the saw blade of high degree of sharpness and good abrasion in order to meet the needs of their daily stone processing

-

The second type of clients:The second type of clients:They come from all over the world,There are a large number of saw blades in their order.so they are cautious when they buy products from abroad every time,They pursue details extremely,From all aspects to test the saw blade,whether it's sharpness or longevity,they want to be better.then they came to China to look for a kind of saw blade with superb performance in order to meet all their requirements perfectly.

-

The third type of clients:The third type of clients:They have a wide range of customers, huge number from different parts of the country,They need to buy a lot of saw blades frequently,so they need a kind of saw blades which can cut different stones stablely.at the same time,the saw blades must keep a large stock to ensure that their customers are satisfied with the quality of the product, without delay their purchase cycle

-

The fourth category of customers:The fourth category of customers: Compared to the cost of saw blade, they are more valued safety and quality of the saw blade, their losses are huge for any safety accident, so their demand is no fall teeth or out of shape.

-

The fifth category of customers:The fifth category of customers:They have huge stone quantity, and the consumption of saw blades is extremely large, the biggest challenge that they faced with is how to smoothly complete a project with limited time under the reasonable cost. They need a sharp and long lifespan saw blade to help them solve the problem.

-

The sixth category of customers:The sixth category of customers: Stone factory is the permanent place that they stay across the country, and their clients target in high-end stone, while they asked for saw blades with high performance cost, not only the cutting effect is stable, lifespan should also be excellent.

.jpg)

Mr. Chen use Black Queen to cutting high-grade and super hard marble

“Having cutting marble for 10 years with many marble saw blades, we have tried many brands for better effect, but once we try Yintian Red queen out, we set it as our only brand for high-end marble cutting immediately, Yintian Red queen is the best!” Mr. Chen praised. There was a time when he didn’t find a satisfying supplier, and always disappointed at the chipping and breaking of the marble, leaving along the high expenses of the raw board, they have a less good reputation due to cutting effect. But all of these went away after his 3 months testing Yintian Red queen, he also introduce the blades to his business clients as its remarkable quality.

Choose the Wear-resistant and sharp Black Queen to cutting marble

Every time when Mr. Du was asked to introduce the marble diamond saw blade, Yintian White angel would always be his answer, not only high effienct, but also great sharpness, White angel won the preference of him. While cutting Nizwz K3 and Altman those stone with fragile feature, the board is straight with no chipping.”As a result of customers’ evaluation, I have a lot of new customers,the perfect cutting performance,long spanlife of White Angle stabilize these customers and driving my other affiliate business.Thank you very much for Yintian.Mr.Du also said he will tell this to his brother who sold diamond tools in another city,Yintian White Angle can bring more customers, and quickly cooperate with Yintian, so that the business will certainly be hot up.

Mr. Wu who come from Huangmei favored Yintian Black Queen series marble saw blade

“Bargin Blue is the most cost-effective and affordable.”Mr.Wu told the product consultant admiringly in the return call.Mr. Huang is a stone shop owner,he is more concerned about the price,Yellow Scud series saw blade have a good cutting performance for cutting medium and high hardness stone and it’s the best choice to cut the special granite which is loose and fragile such as Angola Black, African Persa etc. “To meet customer requirements with High feeding speed and high cutting efficiency” Before Yintian marble saw blade is not used ,we always buy the generla saw blade from the market, there is no discount in price and the cutting effect is not even up to the requirements of ordinary stone cutting.When Yintian product consultant called me I just try to buy a few pieces of saw blade for testing,I did not expect the price of the blade cutting effect is too surprising,The stone is perfect after cutting,reduce the rate of waste stone material and reached the requirements of the price at beginning.

.png)

.jpg)

.png)

.jpg)

.png)

.jpg)

.png)

.jpg)

.png)

.jpg)

.png)

.jpg)

.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

- comments in total【Write a Review】Customer Reviews