We use marble everywhere in our daily life.Because marble is formed by nature, so it needs to be cut and processed to meet the needs of use.In such a case ,the marble cutting blade is very necessary.Due to the large and fast consumption,some of stone companies have a headache in reducing stone cutting consumption and ensuring the supply of the diamond blades.So stone processing industry has the responsibility to help customers improve the labor productivity,reduce labor intensity and enhance the safety of the working environment,rather than only pursuing economic interests.Otherwise,it will bring inconvenience to users or even become a burden.

.jpg)

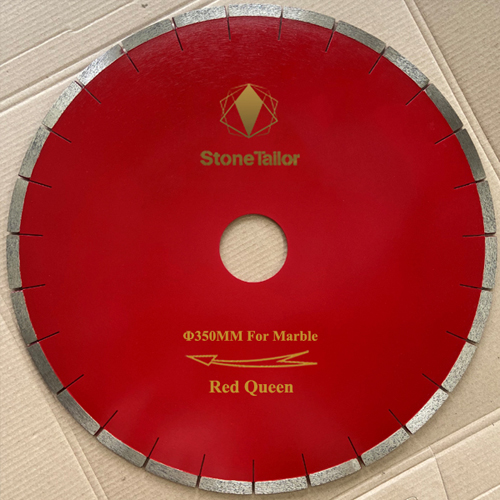

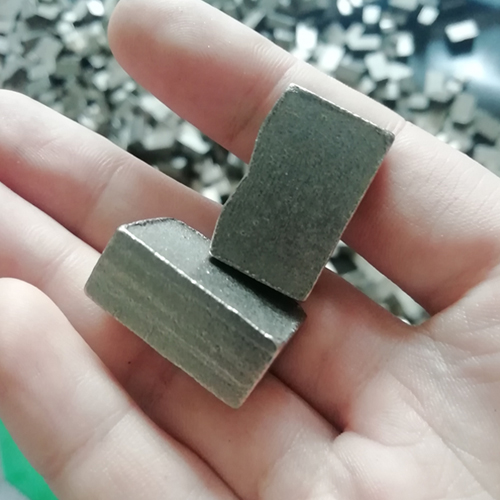

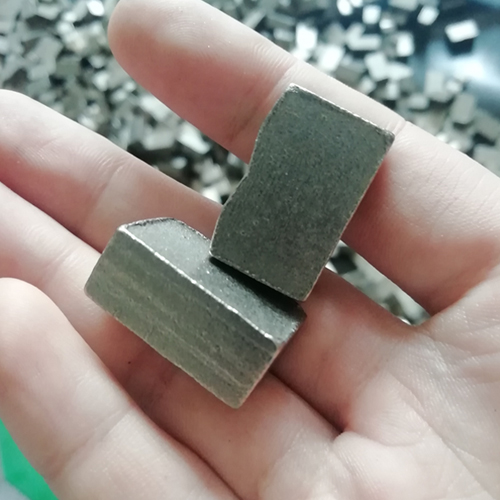

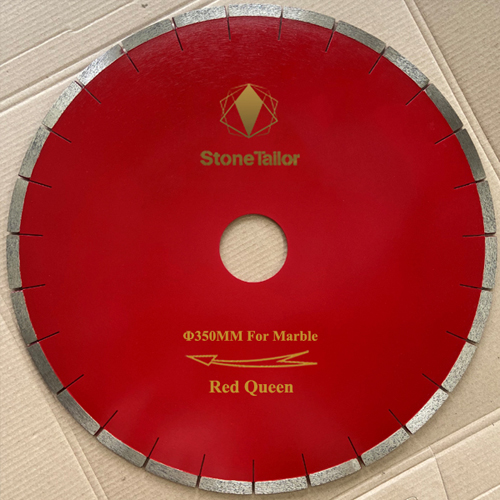

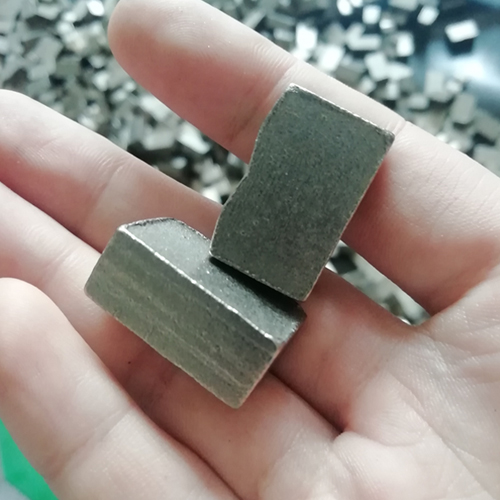

In order to reduce the cost of production,some producers prefer to reduce the diamond content in the blade.It is evident that it will produce a simple and rude product in quality.The customers find the marble blade is so blunt and not durable because the diamonds in segment are not even.There are some phenomena of breaking,chipping and marks happening when cutting,especially for hard marble stones.All the above factors will have an great influence on the efficiency and quality of blades.Hubei YINTIAN Diamond Tools,as an experienced manufacturer from the perspective of the customers,we have launched a high-quality and cost-effective marble cutting blade,Red Queen.which is a marble saw blade of top quality and high cost-effective.

.jpg)

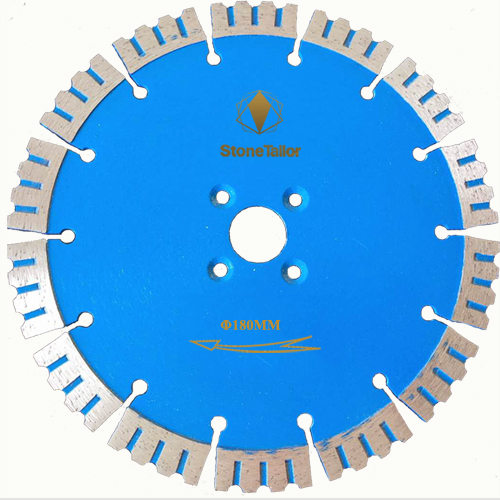

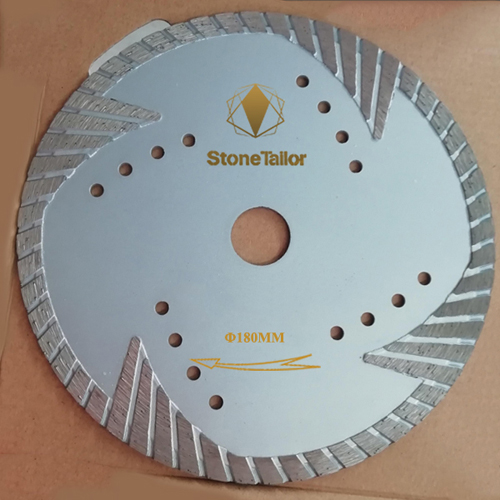

The Red Queen,is a high-quality blade smoothly cutting any marbles with high precision and sharpness,specially designed for valuable,ultra-hard and brittle marble stones.Its high performance is just next to Black Queen,another one top-quality in YINTIAN Diamond Tools.As for The Red Queen Marble cutting blade, we have made significant improvements to the solution for breaking & chipping &vibration in the cutting process.Its Fast feeding speed and stable cutting output help cut out a neat effect and cutting line is pretty smooth and straight.Besides,the Red Queen Diamond Disc for Marble has conquered all kinds of marble stones,not only suitable for cutting hard marbles slabs,but also microlite and artificial stones.The blade goes smoothly and cuts accurately,which appear a remarkable,smooth and sharp the cutting effect without dropping segments.High safety and low noise will greatly increase your efficiency as well.The Red Queen will give you a outstanding consistency performance for cutting various kinds of marbles.

.jpg)

In addition, Red Queen marble saw blades can combine high performance and cost effectiveness at the same time.While it can also provide high sharpness and high precision, it has stable output and consistent effect.It is not only sharp and durable but also has cost-effective performance, which can reduce the consumption of enterprises and the cost of stone processing.It is a great value marble saw blade.

.jpg)

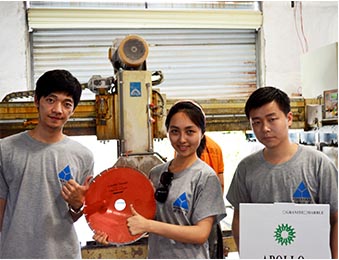

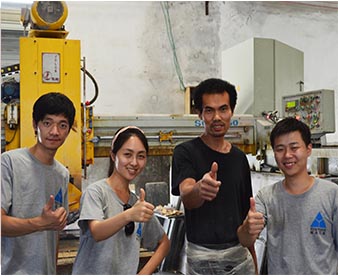

The high quality of Red Queen blade has surprised many customers.One of our foreign dealers specializes in high-grade marble slabs business.He tried the marble saw blades of some factories, but the cutting effect is not satisfactory. The precision and sharpness can not meet their requirements, there is a lot of stone waste and high cost.He couldn't find a satisfactory marble saw blade all the time. Under the introduction of his friends, he began to try the Red Queen marble saw blade in Hubei YINTIAN. After the several trials, he was very satisfied and chose to cooperate with us for a long time. He said that under the condition of ensuring safety and wear resistance, the marble saw blade of Hubei YINTIAN is sharp and accurate, high-quality and long working life. More importantly, the price also satisfied them, and the unit consumption decreased rapidly.

In nearly 20 years accumulation,according to the needs of customers,we continue to overcome difficulties and constantly design and develop the different uses and performances of marble blade to fit the demands of specific customers at all levels.For the past 10 years,the Red Queen Cutting blade has become a pioneer marble blade in overseas markets.Hubei YINTIAN has also won the trust and support of customers in various markets in the international market.They feel very happy to cooperate with Hubei YINTIAN.

In the future,Hubei YINTIAN will further promote innovation and development to meet the stone processing needs at all levels and bring infinite possibilities for marble cutting blade skills.

|

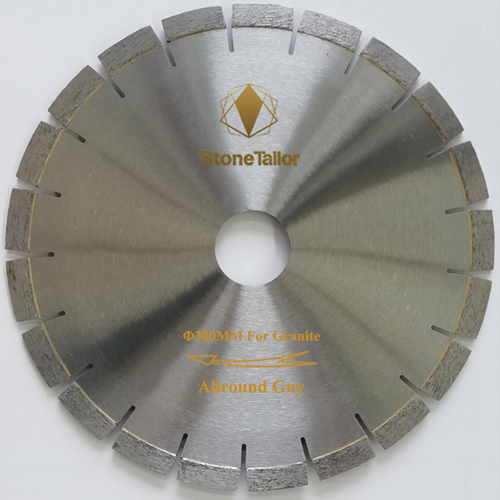

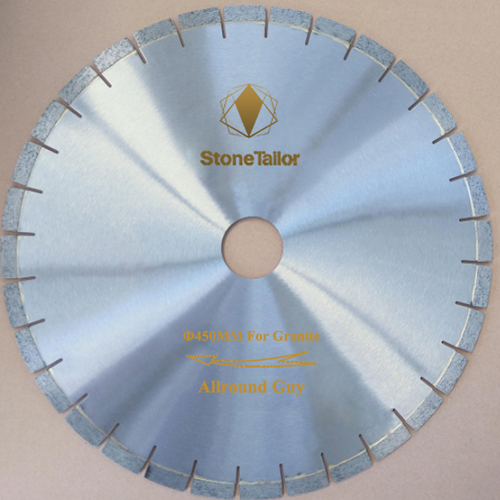

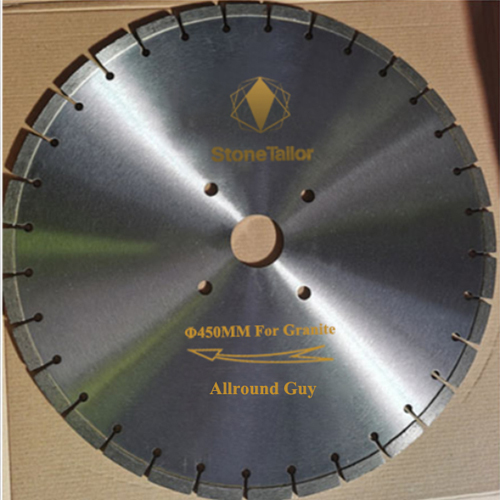

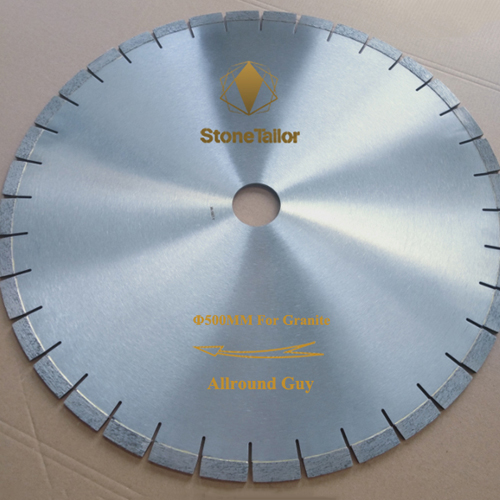

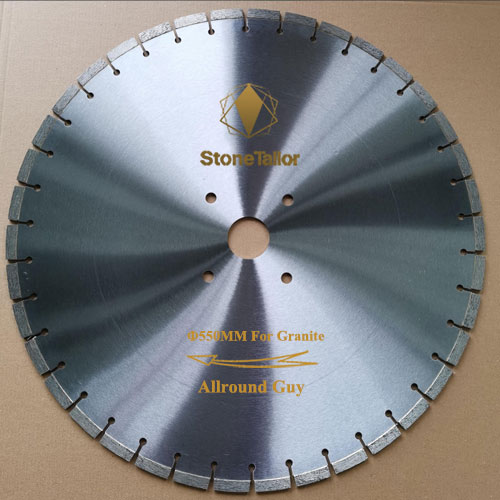

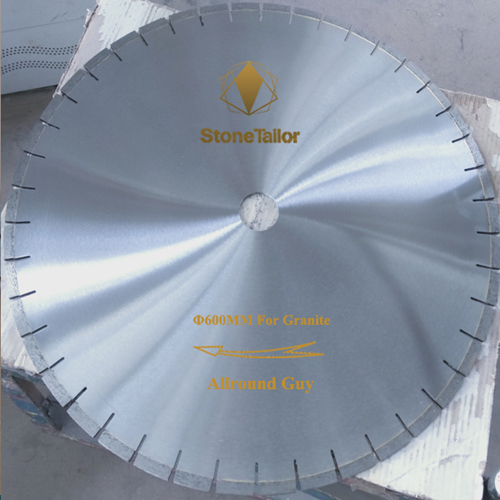

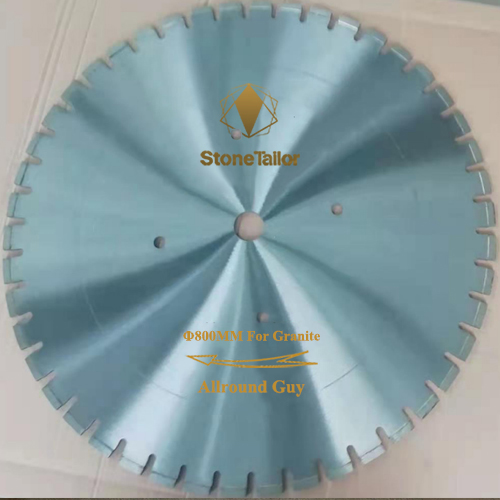

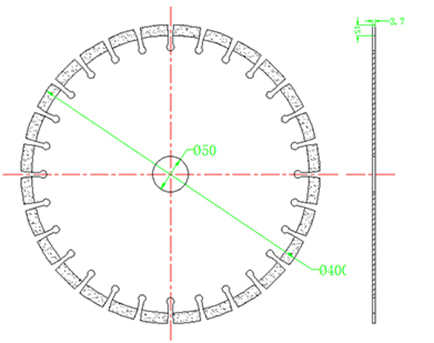

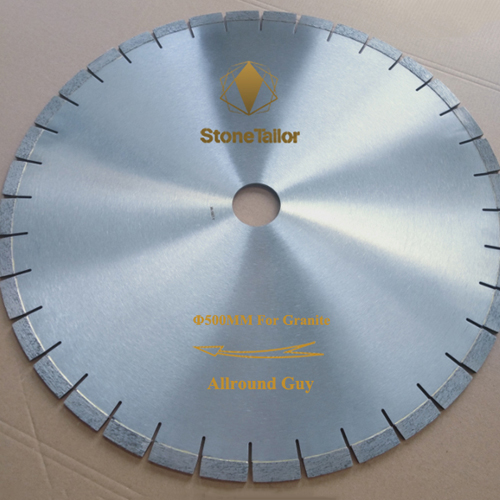

Diamond Saw Blade For Granite 01

|

| ITEM |

DIA.MM |

PICTURE |

TYPE |

SPEC.MM |

HOLES/SLOT |

SERIES |

CODE |

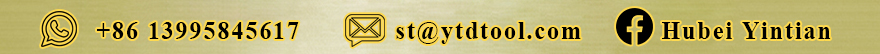

1

|

φ300

12”

|

|

Normal

Silent

|

(40*3.2*15)

*(2.4*21T*50) |

None Hole

U Slot

|

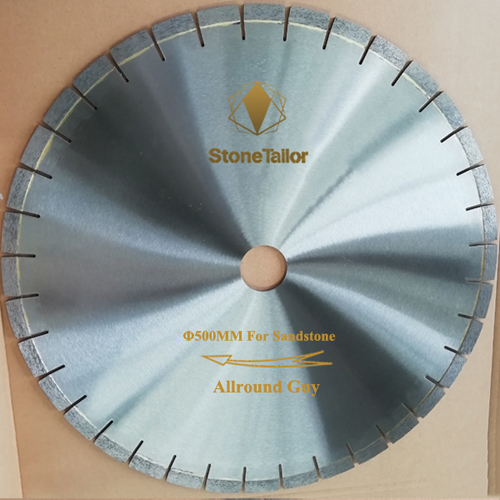

Allround

Guy

|

02

|

2

|

φ350

14''

|

|

Normal

Silent

|

(40*3.3*15)

*(2.4*24T*50)

|

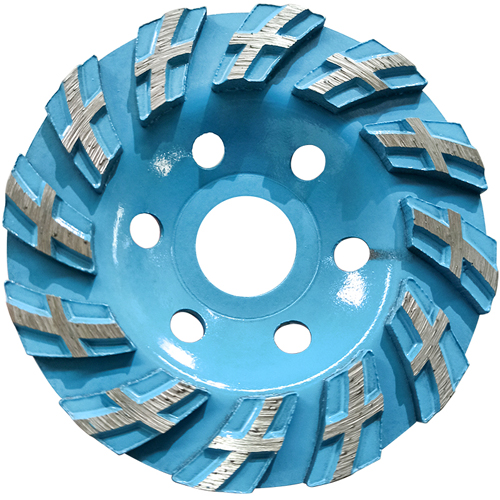

None Hole

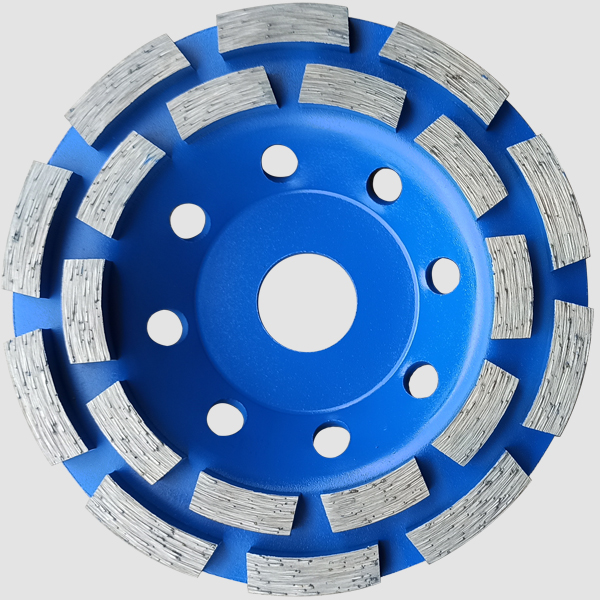

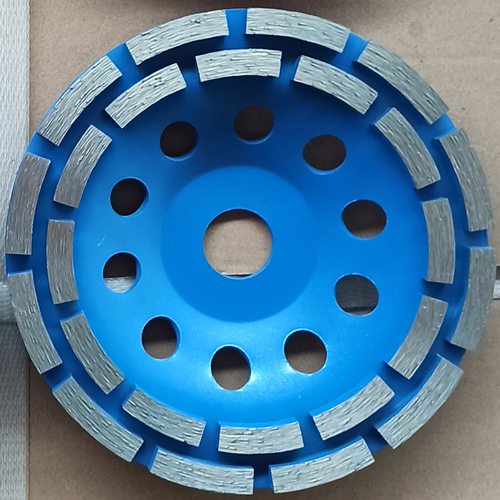

U Slot

|

Allround

Guy

|

02

|

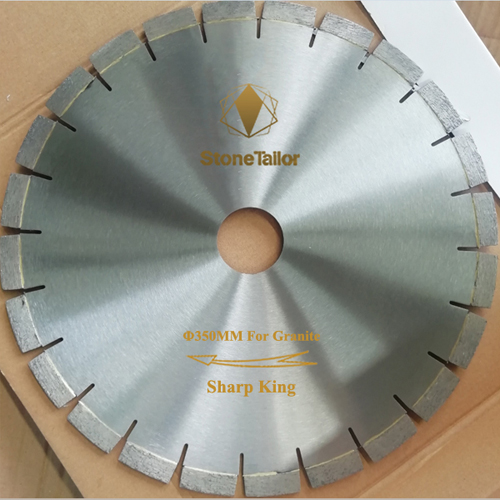

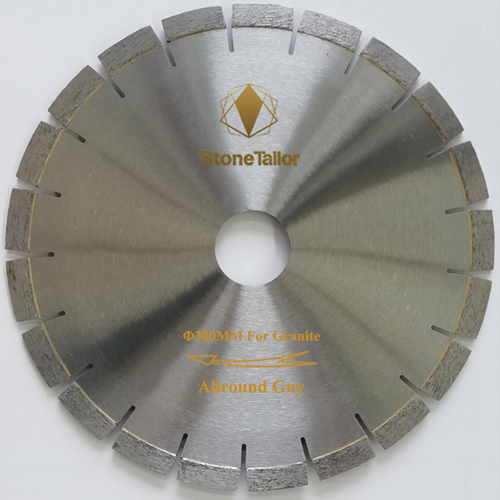

3

|

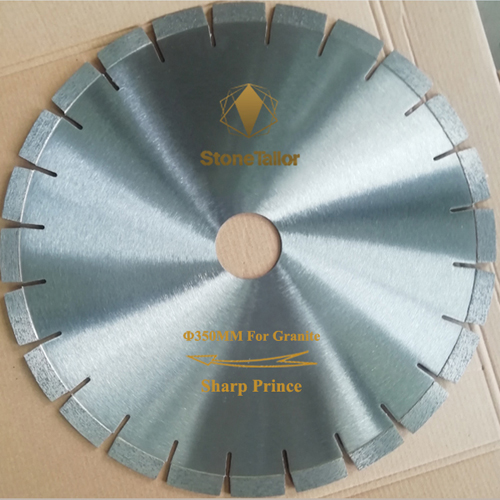

φ350

14''

|

|

Normal

Silent

|

(40*3.3*15)

*(2.4*24T*50)

|

None Hole

U Slot

|

Sharp

King

|

05

|

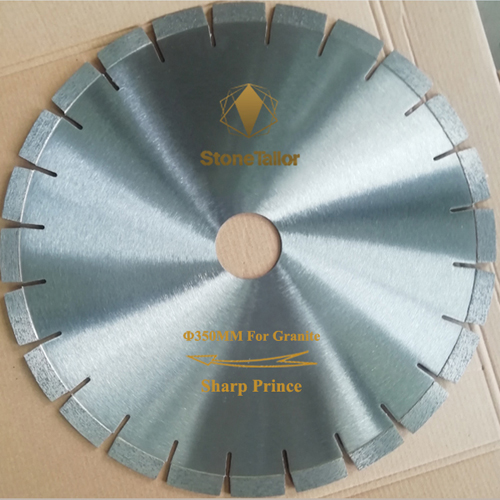

4

|

φ350

14''

|

|

Normal

Silent

|

(40*3.3*15)

*(2.4*24T*50)

|

None Hole

U Slot

|

Sharp

Prince

|

06

|

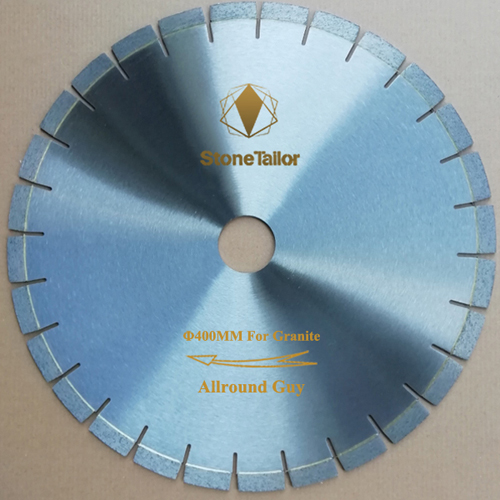

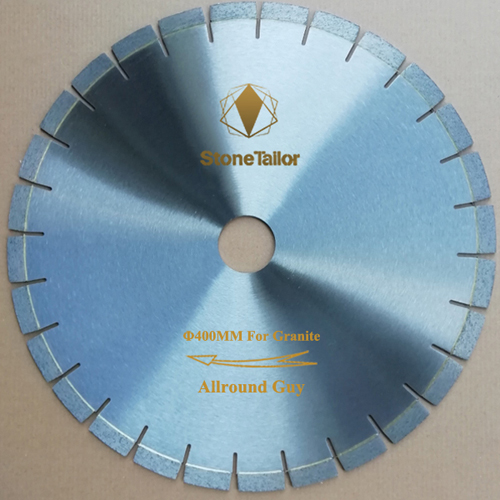

5

|

φ400

16''

|

|

Normal

Silent

|

(40*3.6*15)

*(2.8*28T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

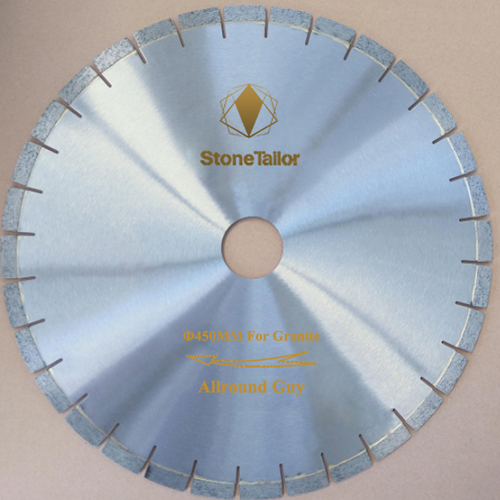

6

|

φ450

18''

|

|

Normal

Silent

|

(40*4.2*12)

*(3.0*32T*50)

|

None Hole

U Slot

|

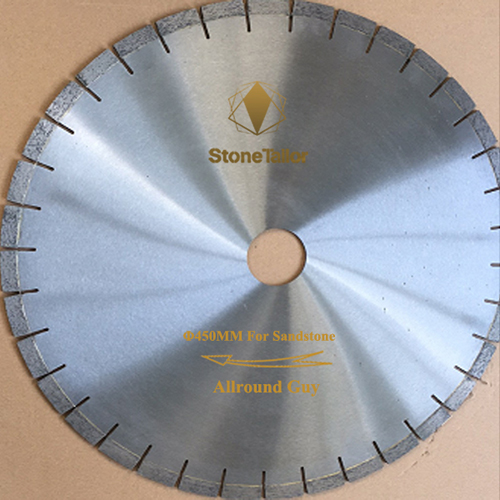

Allround

Guy

|

02

|

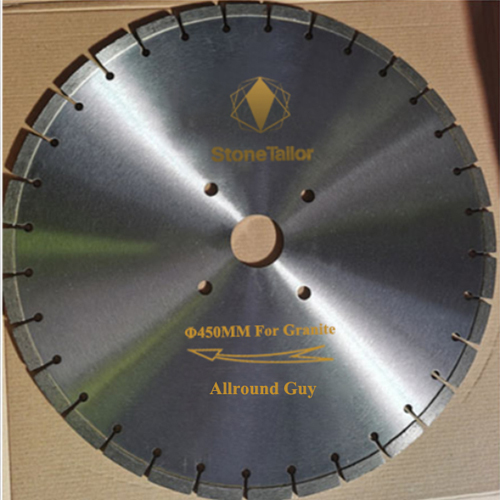

7

|

φ450

18''

|

|

Normal

Silent

|

(40*4.2*15)

*(3.0*32T*50)

|

4 Holes

U Slot

|

Allround

Guy

|

02

|

8

|

φ500

20''

|

|

Normal

Silent

|

(40*4.2*15)

*(3.0*36T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

9

|

φ500

20''

|

|

Normal

Silent

|

(40*4.2*12)

*(3.0*36T*50)

|

None Hole

U Slot

|

Practical

Guy

|

09

|

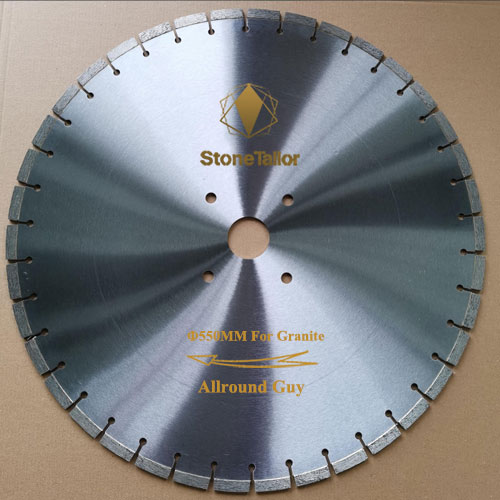

10

|

φ550

22''

|

|

Normal

Silent

|

(40*4.3*12)

*(3.2*38T*50)

|

None Hole

K Slot

|

Allround

Guy

|

09

|

11

|

φ600

24''

|

|

Normal

Silent

|

(40*4.8*12)

*(3.6*42T*50)

|

None Hole

U Slot

|

Practical

Guy

|

09

|

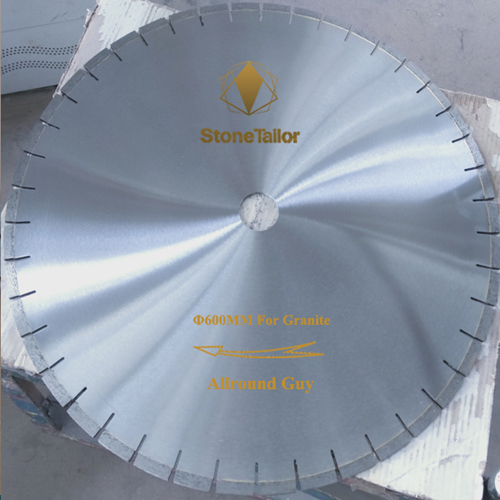

12

|

φ600

24''

|

|

Normal

Silent

|

(40*4.8*15)

*(3.6*42T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

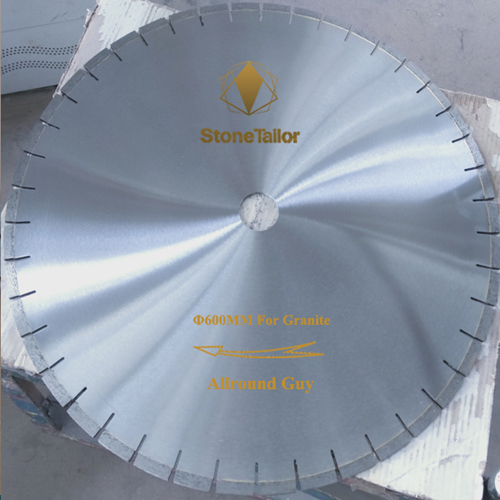

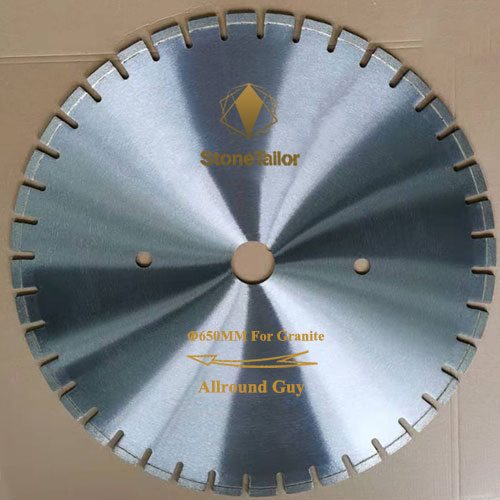

13

|

φ650

26''

|

|

Normal

Silent

|

(40*4.8*12)

*(3.6*40T*50)

|

2 Holes

U Slot

|

Allround

Guy

|

02

|

14

|

φ700

28''

|

|

Normal

Silent

|

(40*5.5*15)

*(4.0*40T*50)

|

4 Holes

U Slot

|

Allround

Guy

|

02

|

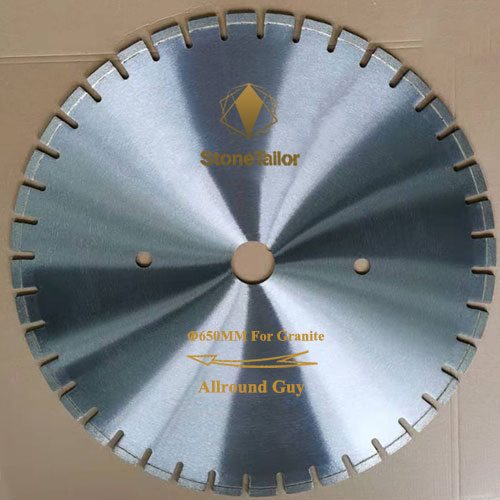

15

|

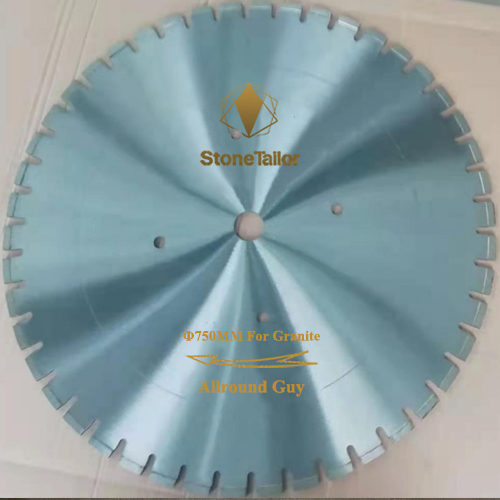

φ750

30''

|

|

Normal

Silent

|

(40*5.5*12)

*(4.0*46T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

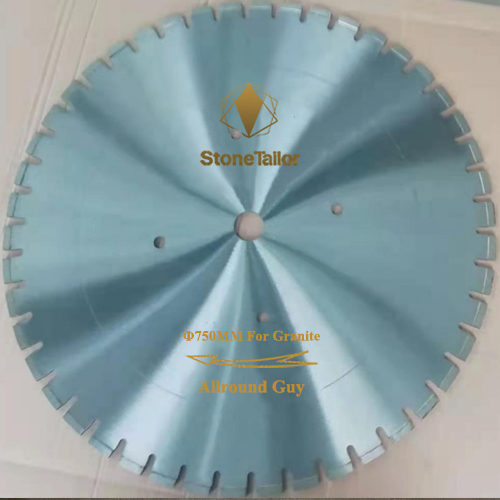

16

|

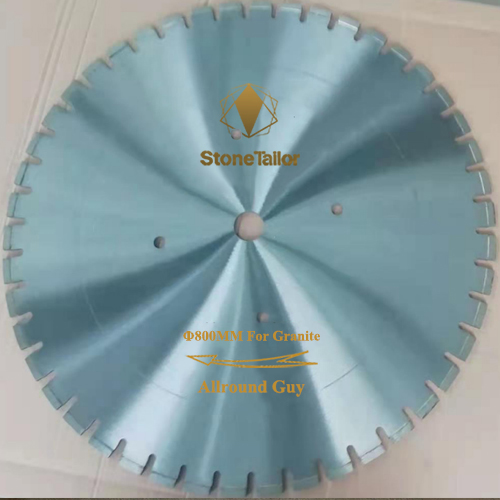

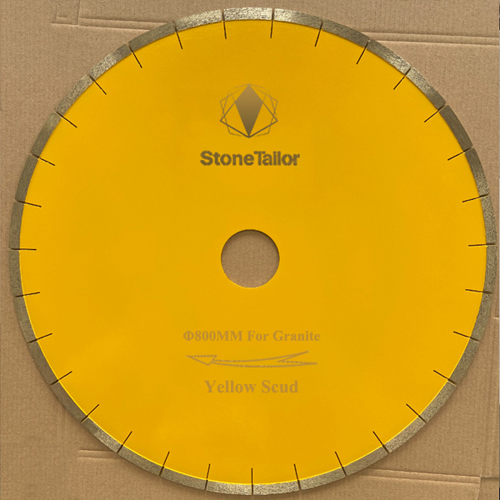

φ800

32''

|

|

Normal

Silent

|

(40*6.0*12)

*(4.5*46T*50)

|

4 Holes

U Slot

|

Allround

Guy

|

02

|

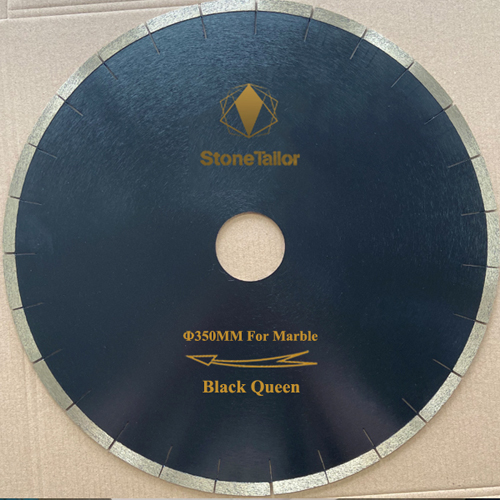

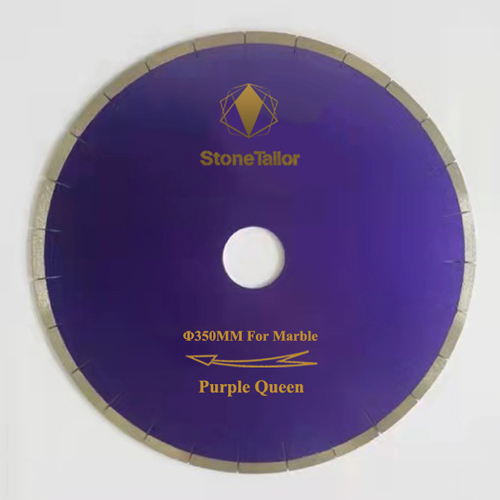

| Diamond Saw Blade For Marble 02 |

| ITEM |

DIA.MM |

PICTURE |

TYPE |

SPEC.MM |

HOLES/SLOT |

SERIES |

CODE |

17

|

φ300

12''

|

|

Normal

Silent

|

(40/39*2.7*8)

*(2.2*23T*50)

|

None Hole

Musical Slot

|

White

Angel

|

12

|

| 18 |

φ350

14''

|

|

Normal

Silent

|

(39/37.8*2.8*9)

*(2.3*27T*50)

|

None Hole

U Slot

|

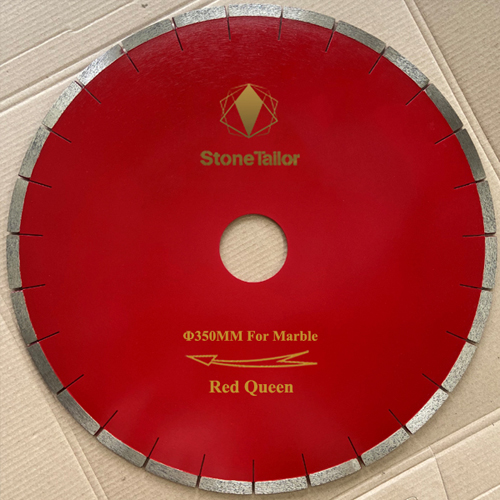

Red

Queen

|

11

|

| 19 |

φ350

14''

|

|

Normal

Silent

|

(39/37.8*2.8*9)

*(2.3*27T*50)

|

None Hole

U Slot

|

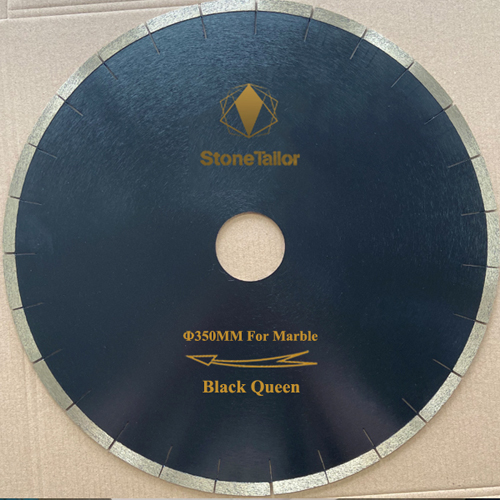

Black

Queen

|

10 |

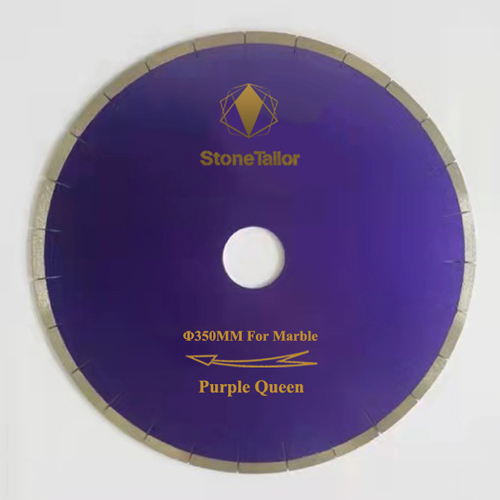

20

|

φ350

14''

|

|

Normal

Silent

|

(39/37.8*2.8*9)

*(2.3*27T*50)

|

None Hole

U Slot

|

Purple

Queen

|

10

|

21

|

φ350

14''

|

|

Normal

Silent

|

(40/39*2.7*8)

*(2.3*27T*50)

|

None Hole

Musical Slot

|

White

Angel

|

12

|

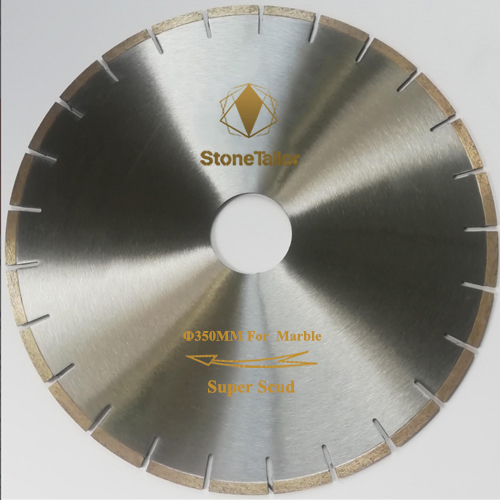

22

|

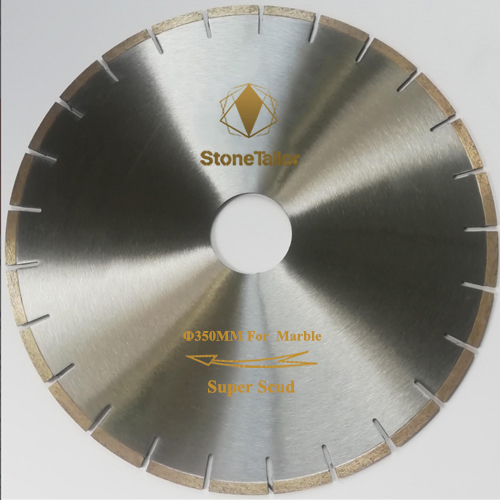

φ350

14''

|

|

Normal

Silent

|

(40/39*2.9*8)

*(2.3*27T*50)

|

None Hole

U Slot

|

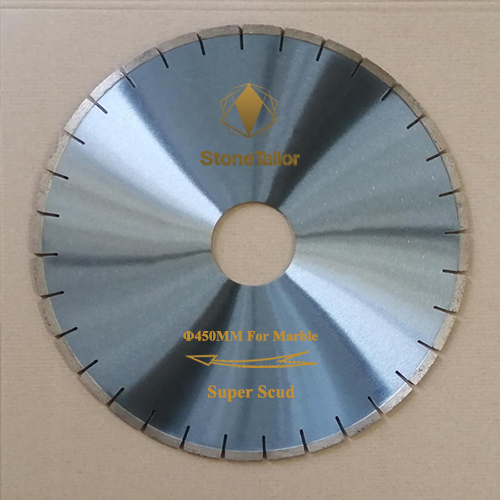

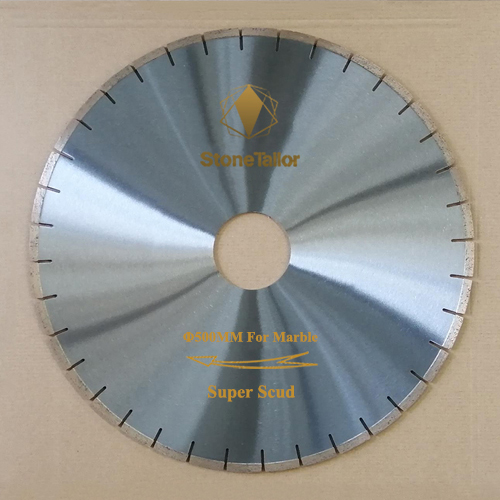

Super

Scud

|

13

|

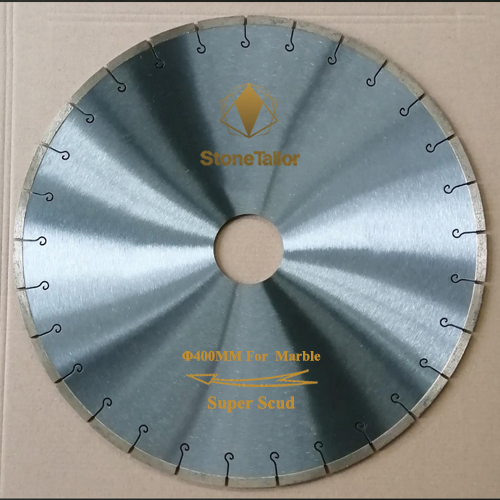

23

|

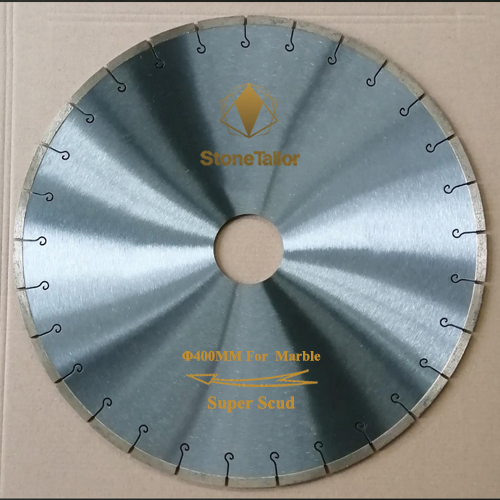

φ400

16''

|

|

Normal

Silent

|

(39/37.8*3.4*9)

*(2.6*31T*50)

|

None Hole

U Slot

|

Super

Scud

|

13

|

24

|

φ400

16''

|

|

Normal

Silent

|

(39/37.8*3.4*9)

*(2.6*31T*50)

|

None Hole

U Slot

|

Red

Queen

|

11

|

25

|

φ400

16''

|

|

Normal

Silent

|

(41.5/40*2.9*8)

*(2.2*30T*50)

|

None Hole

Musical Slot

|

White

Angel

|

12

|

26

|

φ350

14''

|

|

Normal

Silent

|

(43/41.5*2.9*8)

*(2.2*25T*60)

|

None Hole

U Slot

|

Super

Scud

|

13

|

27

|

φ400

16''

|

|

Normal

Silent

|

(40*3.6*10)

*(2.8*28T*60)

|

None Hole

U Slot

|

Super

Scud

|

13

|

28

|

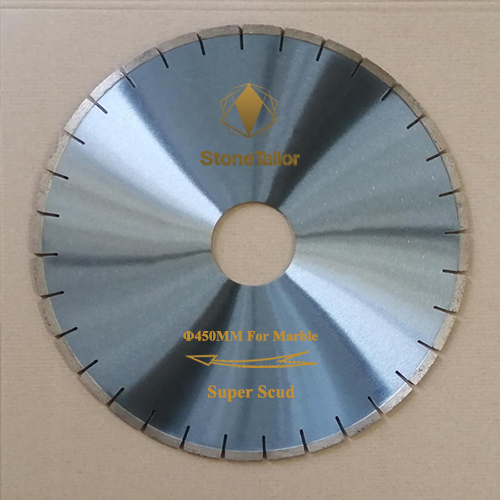

φ450

18''

|

|

Normal

Silent

|

(40*4.2*10)

*(3.0*32T*90/60)

|

None Hole

U Slot

|

Super

Scud

|

13

|

29

|

φ500

20''

|

|

Normal

Silent

|

(40*4.3*10)

*(3.0*36T*50)

|

None Hole

U Slot

|

Scud |

14

|

30

|

φ500

20''

|

|

Normal

Silent

|

(40*4.2*10)

*(3.0*36T*90/60)

|

None Hole

U Slot

|

Super

Scud

|

13

|

| 31 |

φ600

24''

|

|

Normal

Silent

|

(40*4.8*10)

*(3.6*42T*90/60)

|

None Hole

U Slot

|

Super

Scud

|

13

|

32

|

φ650

26''

|

|

Normal

Silent

|

(40*4.8*10)

*(3.6*40T*60)

|

None Hole

U Slot

|

Super

Scud

|

13

|

33

|

φ700

28''

|

|

Normal

Silent

|

(38*5.2*10)

*(4.0*40T*60)

|

None Hole

U Slot

|

Super

Scud

|

13

|

34

|

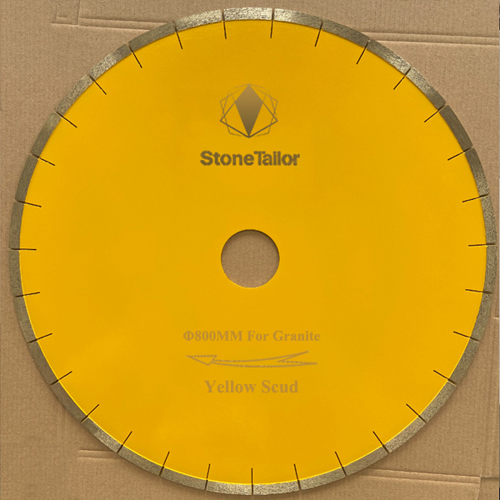

φ800

32''

|

|

Normal

Silent

|

(38*6.0*10)

*(4.5*46T*60)

|

None Hole

U Slot

|

Super

Scud

|

13

|

| Diamond Saw Blade For Sandstone 03 |

| ITEM |

DIA.MM |

PICTURE |

TYPE |

SPEC.MM |

HOLES/SLOT |

SERIES |

CODE |

35

|

φ350

14''

|

|

Normal

Silent

|

(40*3.3*15)

*(2.4*24T*50)

|

None Hole

U Slot

|

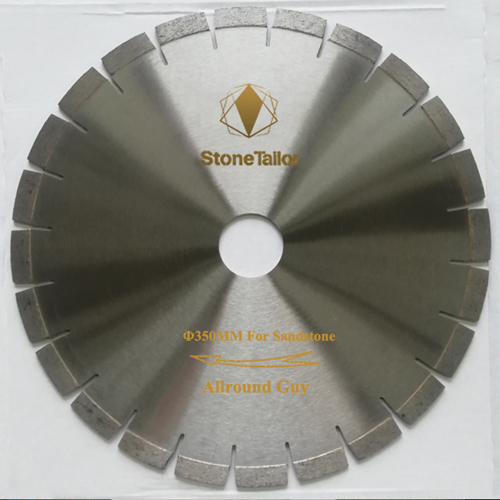

Allround

Guy

|

02

|

36

|

φ400

16''

|

|

Normal

Silent

|

(40*3.8*15)

*(2.8*28T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

37

|

φ450

18''

|

|

Normal

Silent

|

(40*4.0*15)

*(3.0*32T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

38

|

φ500

20''

|

|

Normal

Silent

|

(40*4.2*15)

*(3.0*36T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

39

|

φ600

24''

|

|

Normal

Silent

|

(40*4.5*15)

*(3.6*42T*50)

|

None Hole

U Slot

|

Allround

Guy

|

02

|

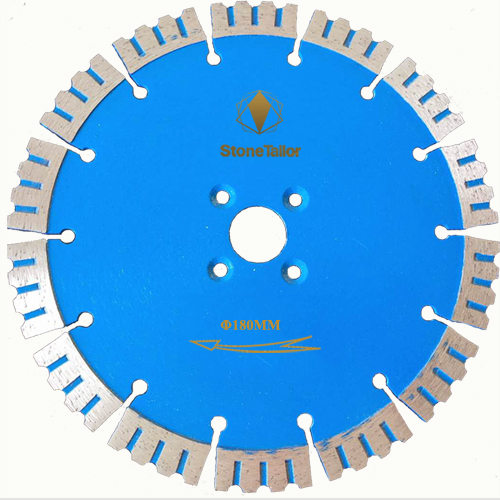

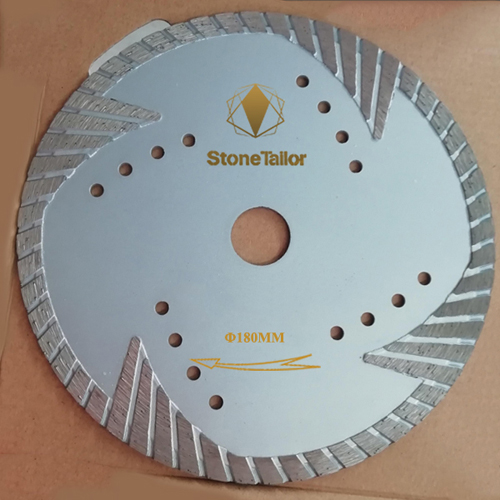

| Diamond Saw Blade For Hot-press 04 |

| ITEM |

DIA.MM |

PICTURE |

TYPE |

SPEC.MM |

HOLES/SLOT |

SERIES |

CODE |

40

|

φ110

4.5''

|

|

Protective

-teeth

|

2.0T*10X*1.2E*

9Z*22.23H

|

None Hole

U Slot

|

Allround

Guy

|

02

|

| 41 |

φ115

4.5''

|

|

Protective

-teeth

|

2.0T*15X*1.4E*

8Z*22.23H

|

None Hole

K Slot

|

Allround

Guy

|

02

|

42

|

φ125

5''

|

|

Segmented

T-teeth

|

2.2T*10X*1.2E*

10Z*22.23H

|

None Hole

U Slot

|

Allround

Guy

|

02

|

|

43

|

φ180

7''

|

|

Flower-teeth

|

2.4T*10X*1.6E*

14Z*22.23H

|

4 Holes

K Slot

|

Allround

Guy

|

02

|

|

44

|

φ180

7''

|

|

Triangular

-turbo

|

2.6T*10X*1.8E*

22.23H*Rim

|

12 Holes

Rim

|

Allround

Guy

|

02

|

|

45

|

φ180

7''

|

|

Rimmed

T-teeth

|

2.6T*10X*1.8E*

22.23H*Rim

|

15 Holes

Rim

|

Allround

Guy

|

02

|

|

46

|

φ230

9''

|

|

Protective

-teeth

|

2.6T*10X*1.8E*

21Z*22.23H

|

None Hole

U Slot

|

Allround

Guy

|

02

|

|

47

|

φ230

9''

|

|

Triangular

-turbo

|

2.8T*10X*2.0E*

22.23H*Rim

|

30 Holes

Rim

|

Allround

Guy

|

02

|

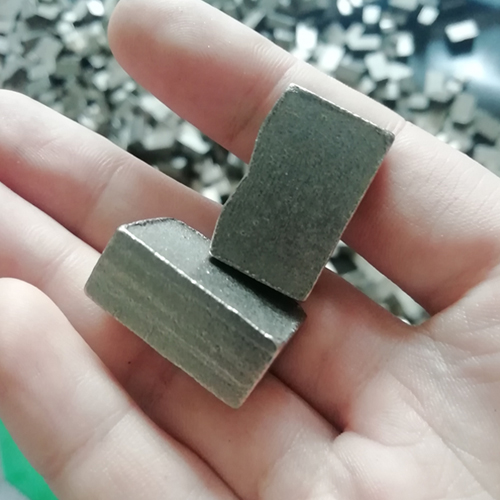

| Diamond Segments For Sandstone 05 |

| ITEM |

DIA.MM |

PICTURE |

THICKNESS |

SPEC.MM |

SEG. No |

SERIES |

CODE |

48

|

φ1600

64''

|

|

7.2

|

24*8.4/9.0*15/14

|

80 PCS

|

Allround

Guy

|

02

|

49

|

φ1600

64''

|

|

7.2

|

24*8.4/9.0*15/14

|

80 PCS

|

Allround

Guy

|

02

|

50

|

φ1600

64''

|

|

7.2

|

24*8.4/9.0*15 |

80 PCS

|

Allround

Guy

|

02

|

51

|

φ1600

64''

|

|

7.2

|

24*9.6/10.2*15/14 |

80 PCS

|

Allround

Guy

|

02

|

| Diamond Segments For Marble 06 |

| ITEM |

DIA.MM |

PICTURE |

THICKNESS |

SPEC.MM |

SEG. No |

SERIES |

CODE |

| 52 |

φ1600

64''

|

|

7.2/8

|

24*8.4/9.0*15 |

80 PCS

|

Allround

Guy

|

02

|

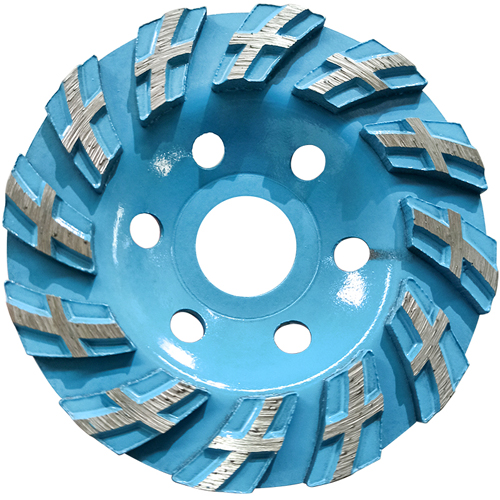

| For Cup Grinding Wheel 07 |

| ITEM |

DIA.MM |

PICTURE |

TYPE |

SPEC.MM |

HOLES/SLOT |

SERIES |

CODE |

53

|

φ100

4''

|

|

Cross-teeth

|

5.7*12*20/22.23

with Rings

|

Cross-teeth

Seg./11

|

Allround

Guy

|

02

|

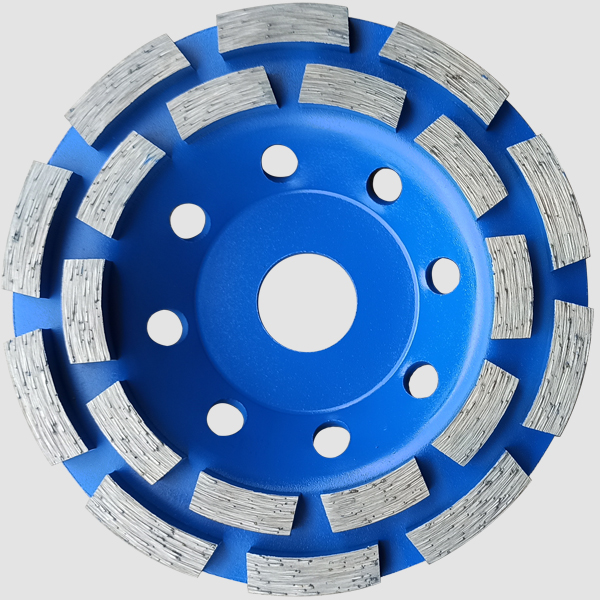

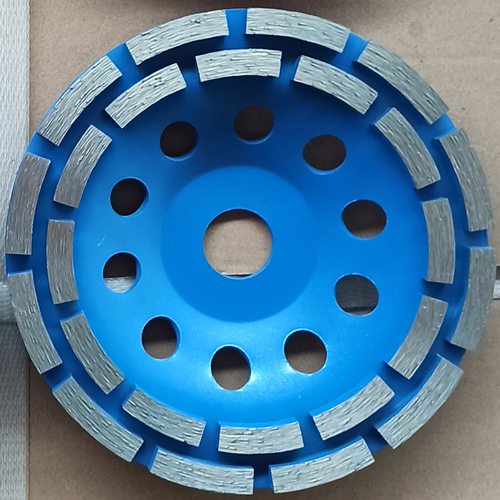

54

|

φ100

4''

|

|

Double-row

|

7*(8*2)

*22.23

|

Double-row

Seg./8*2

|

Allround

Guy

|

02

|

55

|

φ115

4.6''

|

|

Double-row

|

7*(9*2)

*22.23

|

Double-row

Seg./9*2

|

Allround

Guy

|

02

|

56

|

φ125

5''

|

|

Double-row

|

7*(10*2)

*22.23

|

Double-row

Seg./10*2

|

Allround

Guy

|

02

|

57

|

φ150

6''

|

|

Double-row

|

7*(12*2)

*22.23

|

Double-row

Seg./12*2

|

Allround

Guy

|

02

|

58

|

φ180

7''

|

|

Double-row

|

7*(12*2)

*22.23

|

Double-row

Seg./12*2

|

Allround

Guy

|

02

|

59

|

φ100

4''

|

|

Aluminuim

|

7.5*24

*M14

|

M14

&5/8-1

|

Allround

Guy

|

02

|

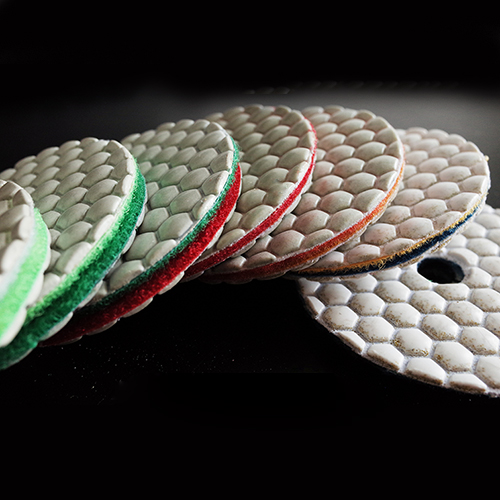

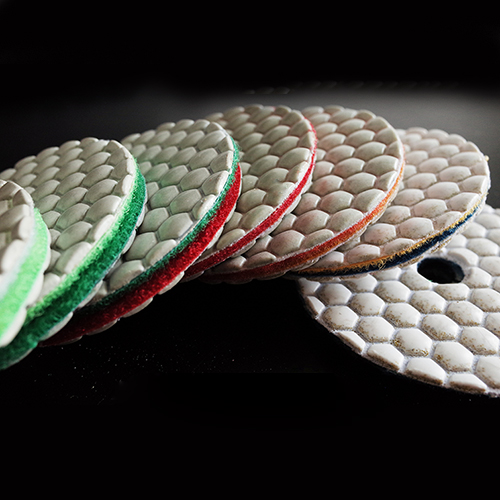

| For Polishing Pad 08 |

| ITEM |

DIA.MM |

PICTURE |

TYPE |

GRITS |

THICKNESS |

SERIES |

CODE |

| 60 |

φ100

4''

|

|

Convex-tooth

Dry

|

50# 100# 200#

400# 800# 1500#

3000# Buff#

|

2.5MM

|

Allround

Guy

|

02

|

61

|

φ100

4''

|

|

Flat-tooth

Dry

|

50# 100# 200#

400# 800# 1500#

3000# Buff#

|

2.5MM

|

Allround

Guy

|

02

|

62

|

φ100

4''

|

|

Flat-tooth

Wet

|

50# 100# 200#

400# 800# 1500#

3000# Buff#

|

3MM

|

Allround

Guy

|

02

|

-

Marble Blades Cutting Slabs

-

Marble Blades Cutting Slabs

-

Marble Blades Cutting Slabs

Saw Blades Cut

the Marble Stone use for Stairs

-

Saw Blades Cut

the Marble Stone use for Floor tile

-

Saw Blades Cut

the Marble Stone use for exterior wall

-

Saw Blades Cut

the Marble Stone Cabinet board

.jpg)

-

The first type of clients:The first type of clients:The structure of the stone that they are processing is complex.for example,for example,They cut varieties granite plate with larger quartz particles,high sand content,close coexists and high abrasiveness ,thus the segment easily get chipping in the cutting process.so They must choose the saw blade of high degree of sharpness and good abrasion in order to meet the needs of their daily stone processing

-

The second type of clients:The second type of clients:They come from all over the world,There are a large number of saw blades in their order.so they are cautious when they buy products from abroad every time,They pursue details extremely,From all aspects to test the saw blade,whether it's sharpness or longevity,they want to be better.then they came to China to look for a kind of saw blade with superb performance in order to meet all their requirements perfectly.

-

The third type of clients:The third type of clients:They have a wide range of customers, huge number from different parts of the country,They need to buy a lot of saw blades frequently,so they need a kind of saw blades which can cut different stones stablely.at the same time,the saw blades must keep a large stock to ensure that their customers are satisfied with the quality of the product, without delay their purchase cycle

-

The fourth category of customers:The fourth category of customers: Compared to the cost of saw blade, they are more valued safety and quality of the saw blade, their losses are huge for any safety accident, so their demand is no fall teeth or out of shape.

-

The fifth category of customers:The fifth category of customers:They have huge stone quantity, and the consumption of saw blades is extremely large, the biggest challenge that they faced with is how to smoothly complete a project with limited time under the reasonable cost. They need a sharp and long lifespan saw blade to help them solve the problem.

-

The sixth category of customers:The sixth category of customers: Stone factory is the permanent place that they stay across the country, and their clients target in high-end stone, while they asked for saw blades with high performance cost, not only the cutting effect is stable, lifespan should also be excellent.

.jpg)

Mr. Chen use Red Queen to cutting high-grade and super hard marble

“Having cutting marble for 10 years with many marble saw blades, we have tried many brands for better effect, but once we try Yintian Red queen out, we set it as our only brand for high-end marble cutting immediately, Yintian Red queen is the best!” Mr. Chen praised. There was a time when he didn’t find a satisfying supplier, and always disappointed at the chipping and breaking of the marble, leaving along the high expenses of the raw board, they have a less good reputation due to cutting effect. But all of these went away after his 3 months testing Yintian Red queen, he also introduce the blades to his business clients as its remarkable quality.

Choose the Wear-resistant and sharp Red Queen to cutting marble

Every time when Mr. Du was asked to introduce the marble diamond saw blade, Yintian White angel would always be his answer, not only high effienct, but also great sharpness, White angel won the preference of him. While cutting Nizwz K3 and Altman those stone with fragile feature, the board is straight with no chipping.”As a result of customers’ evaluation, I have a lot of new customers,the perfect cutting performance,long spanlife of White Angle stabilize these customers and driving my other affiliate business.Thank you very much for Yintian.Mr.Du also said he will tell this to his brother who sold diamond tools in another city,Yintian White Angle can bring more customers, and quickly cooperate with Yintian, so that the business will certainly be hot up.

Mr. Wu who come from Huangmei favored Yintian Red Queen series marble saw blade

“Bargin Blue is the most cost-effective and affordable.”Mr.Wu told the product consultant admiringly in the return call.Mr. Huang is a stone shop owner,he is more concerned about the price,Yellow Scud series saw blade have a good cutting performance for cutting medium and high hardness stone and it’s the best choice to cut the special granite which is loose and fragile such as Angola Black, African Persa etc. “To meet customer requirements with High feeding speed and high cutting efficiency” Before Yintian marble saw blade is not used ,we always buy the generla saw blade from the market, there is no discount in price and the cutting effect is not even up to the requirements of ordinary stone cutting.When Yintian product consultant called me I just try to buy a few pieces of saw blade for testing,I did not expect the price of the blade cutting effect is too surprising,The stone is perfect after cutting,reduce the rate of waste stone material and reached the requirements of the price at beginning.

.png)

.jpg)

.png)

.jpg)

.png)

.jpg)

.png)

.jpg)

.png)

.jpg)

.png)

.jpg)

.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

- comments in total【Write a Review】Customer Reviews